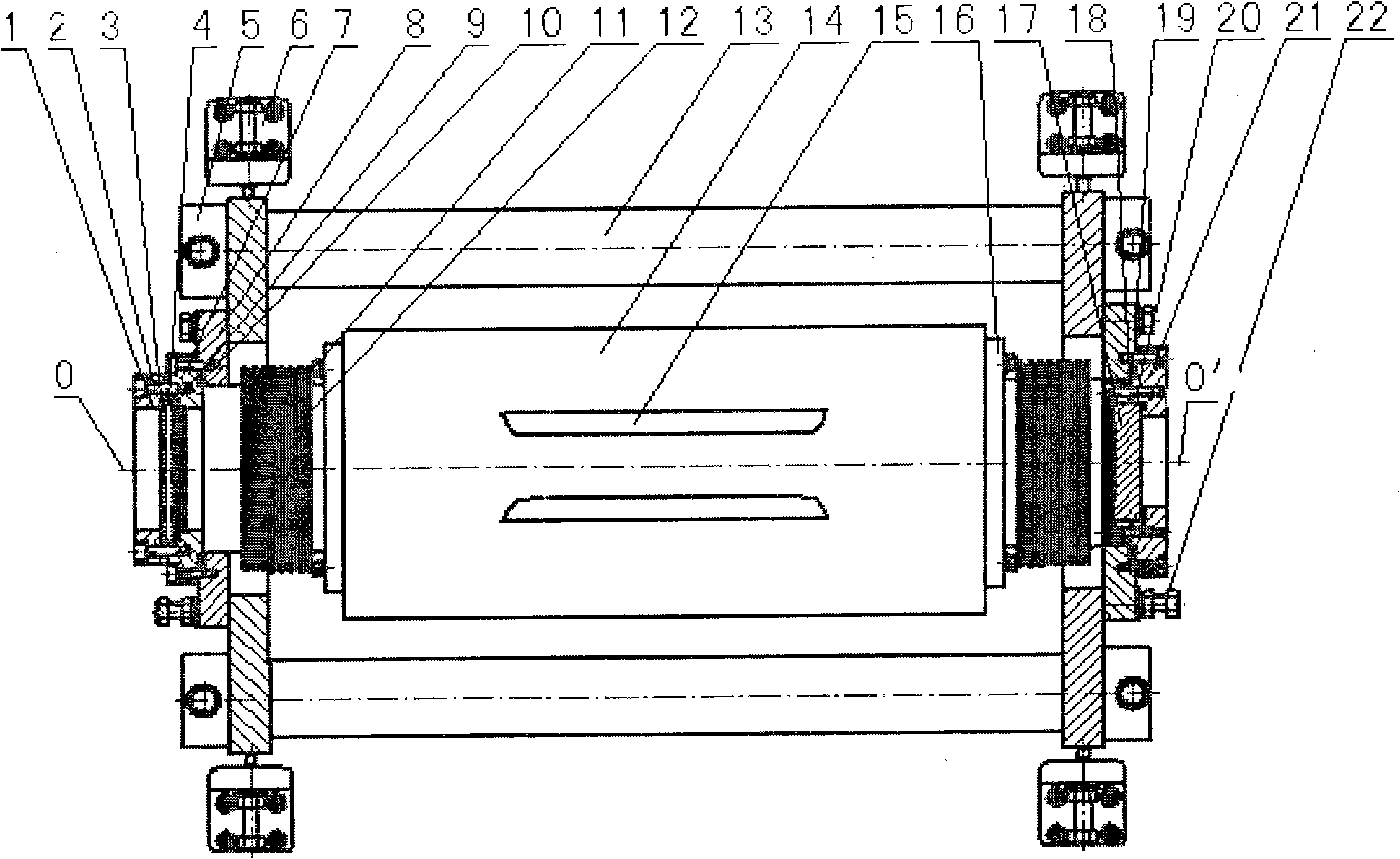

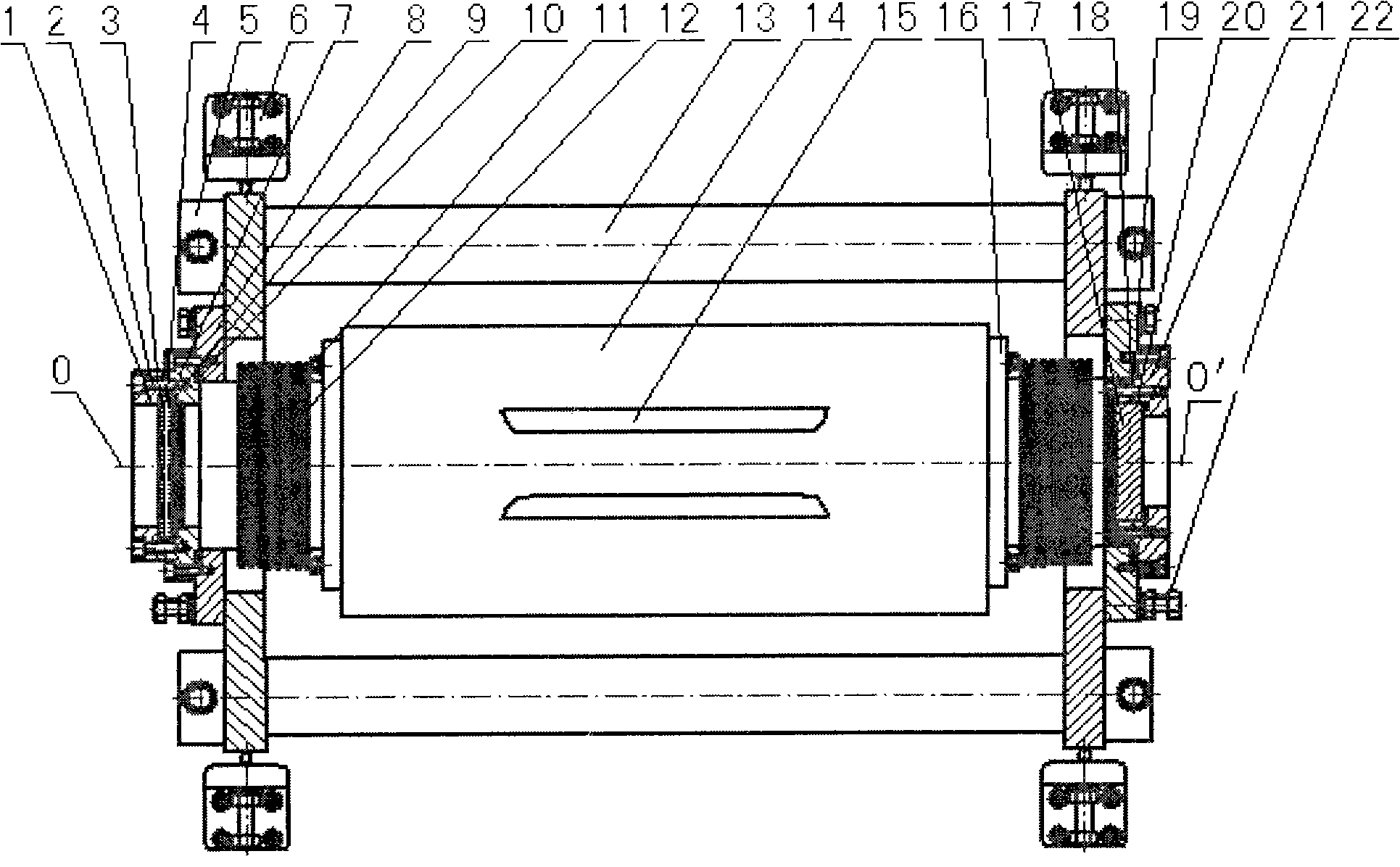

Optical resonator of high-power CO2 gas laser

An optical resonant cavity and high-power technology, which is applied in the direction of lasers, laser components, phonon exciters, etc., to achieve simple technical structure, easy installation and debugging, small and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0015] The gas CO of the present invention 2 The laser optical resonator device includes: output reflector gland 1; M6 socket head cap screw 2; indium steel washer 3; output reflector (output window) 4; upper and lower displacement adjustment block 5; left and right displacement adjustment block 6; Output reflector seat 7; bellows large flange 8; medium O-ring 9; large O-ring 10; M6 hex bolt 11; bellows 12; high stability optical bracket 13; laser discharge chamber 14; discharge electrode 15 ; Bellows small flange 16; total reflection mirror 17; total reflection mirror gland 18; small O-ring 19; total reflection mirror seat 21;

[0016] The optical element total reflection mirror is a concave mirror with a diameter of 76.2mm, the radius of curvature R is 18m, and the concave surface is plated with gold, and the total reflection rate is 99.8%; The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com