Optical mode cleaner

A cleaner and optical mode technology, applied in lasers, laser parts, laser parts, etc., can solve the problems of cavity temperature control and stability need to be further improved, and achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

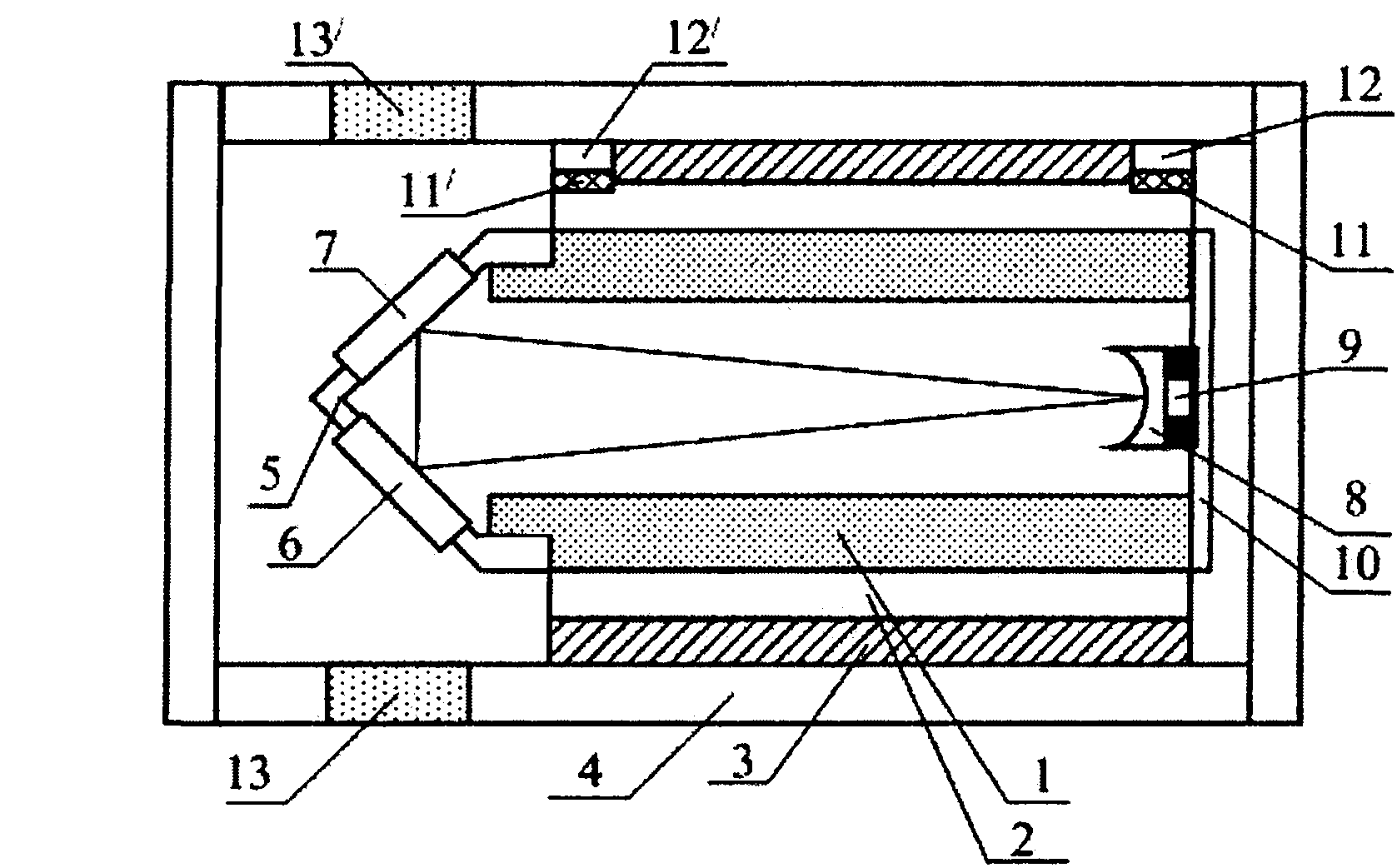

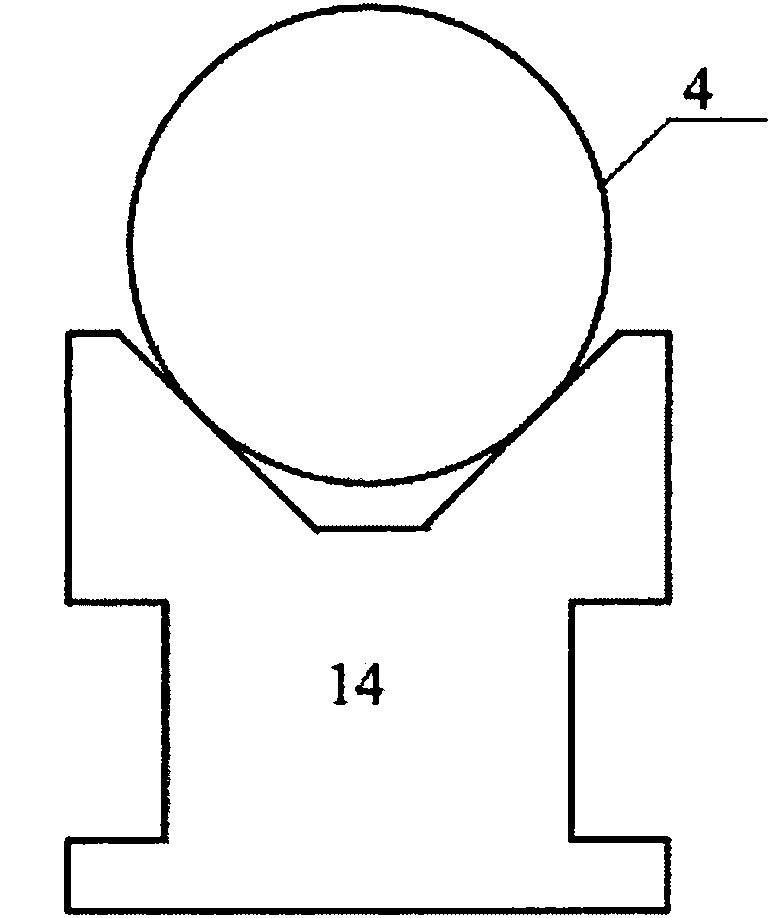

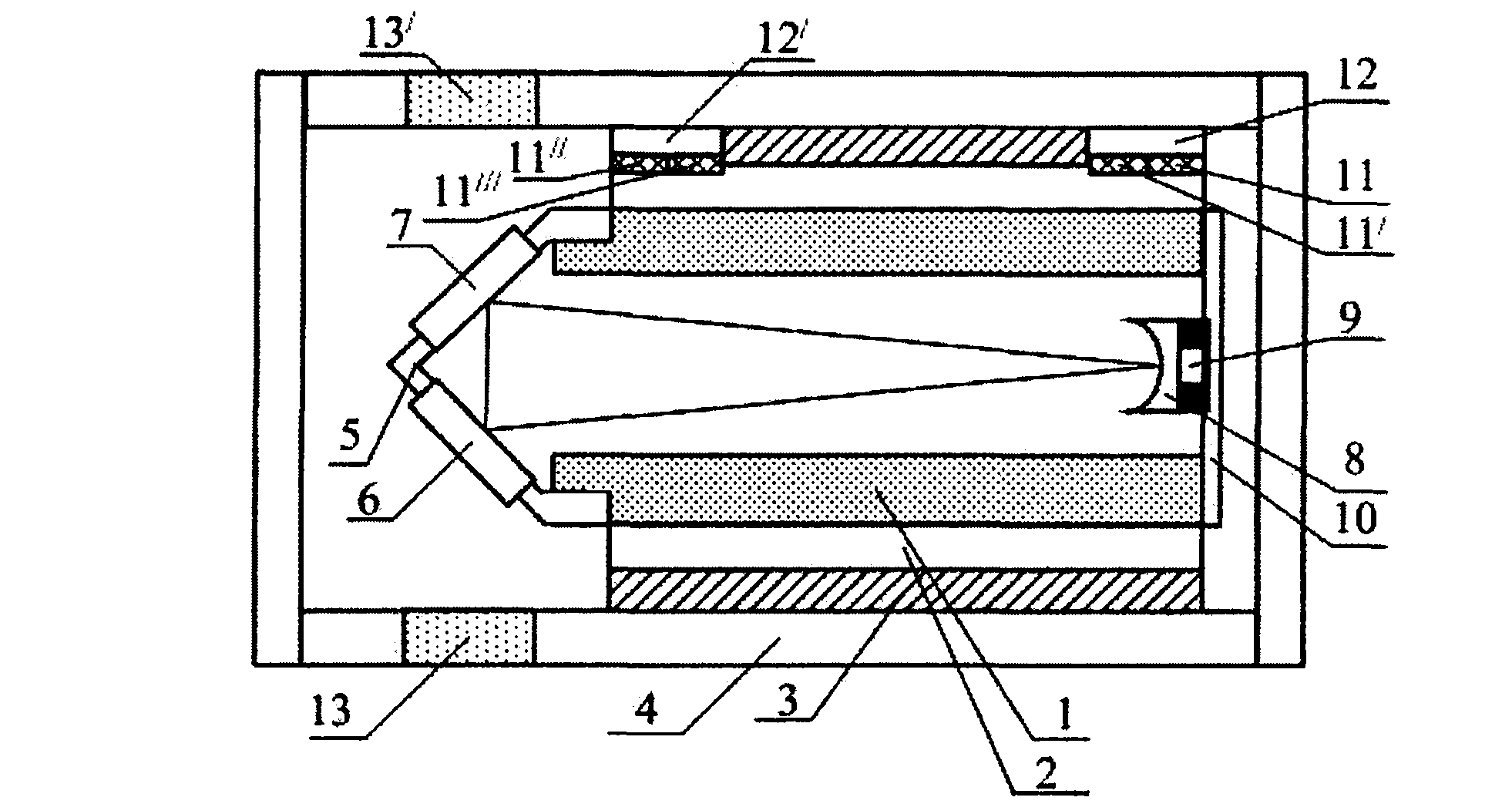

[0020] An embodiment of the present invention, such as figure 1 As shown, the three-mirror annular optical resonant cavity includes a cylindrical cavity 1, a triangular cone-shaped cone 5 and a circular bottom plate 10. The cylindrical cavity 1 is an Invar cylinder with an inner diameter of 25 mm and an outer diameter of 40 mm. One end of the body 1 is closely connected with the cone 5, and the other end is fixed with the circular bottom plate 10 by screws, and indium foil is added on the contact surface to adjust the closure of light in the optical cavity, forming a sealed overall cavity. Plane mirrors 6 and 7 are respectively fixed on two slopes of cone 5, and concave mirror 8 and piezoelectric ceramics 9 are fixed at the central position of circular base plate 10; the reflectivity of plane mirrors 6 and 7 is 99.7%, and the reflection The ratio is 99.95%. Plane mirrors 6 and 7 choose plane mirrors with a diameter of 25mm, and concave mirror 8 chooses a concave mirror with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com