Cleaning ball and processing method thereof

A processing method and technology of cleaning balls, which are applied in the field of sanitary cleaning appliances, can solve the problems of easy pollution of the environment, high strength of steel wires, and mold generation, and achieve the effects of flexible expansion and contraction, high mechanical strength, and moderate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

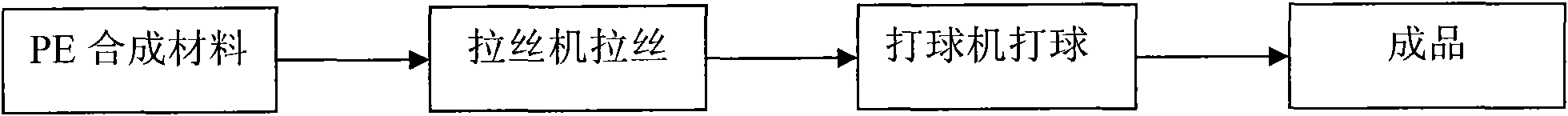

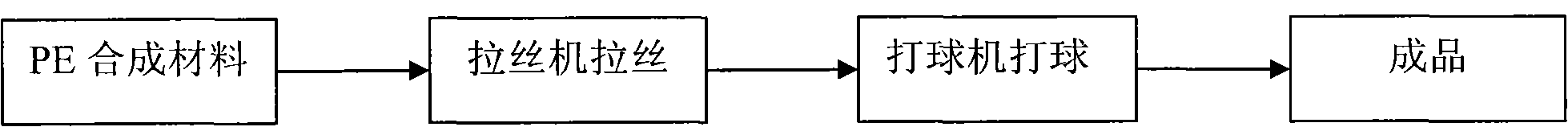

[0011] Referring to the accompanying drawings, the cleaning ball of the present invention is made of polypropylene material through processing.

[0012] For the convenience of users, the diameter of the cleaning ball is no more than 15cm.

[0013] In order to obtain the cleaning ball of the present invention, the present invention adopts the following processing methods:

[0014] Put the polypropylene material into the wire drawing machine for wire drawing, and pull out the filaments with a width of 10-20mm and a thickness of 1-5mm, so that it feels good to use, and then use the drawn filaments to play with a ball-playing machine.

[0015] Contrast situation between existing cleaning ball and the use effect of the present invention

[0016] name

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com