Process for treating domestic rubbish and wastes of agriculture and animal husbandry by low-pressure oxidation degradation method

A domestic waste and oxidative degradation technology, which is applied in the fields of solid waste removal, climate change adaptation, organic fertilizer, etc., can solve the problems of severe chemical reaction conditions, environmental pollution, etc., and achieve the effect of effective treatment and reduction of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

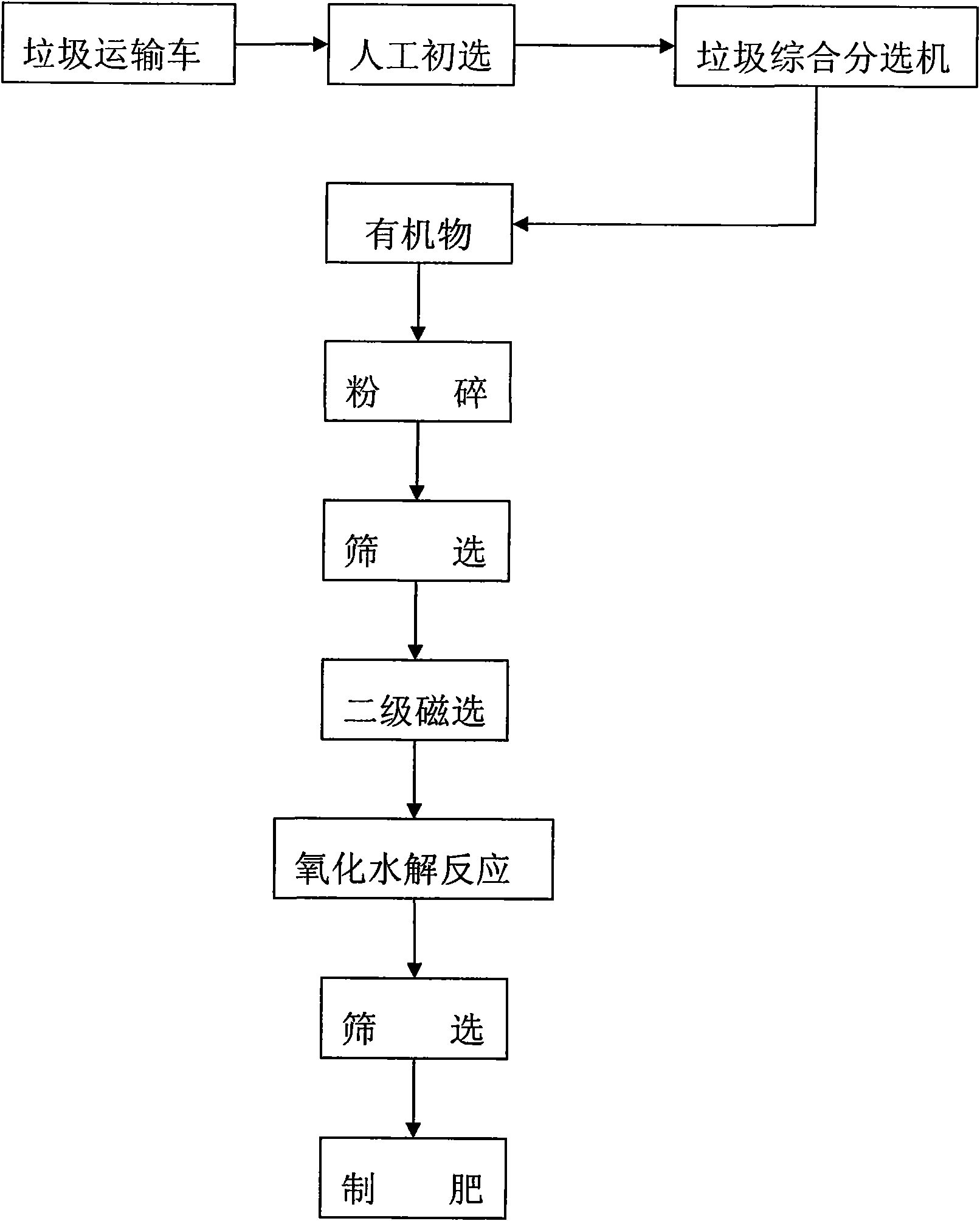

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The raw materials are 50wt% domestic garbage, 50wt% agricultural and animal husbandry waste and biomass waste. The ferromagnetic materials and the raw materials with a particle size of 8mm≤Φ≤68mm are sent to the oxidation kettle through the magnetic separation of the second-level automatic magnetic separation device. When the raw materials enter the oxidation kettle, they are preheated to 60 ℃ the volume percentage of oxygen is 30% oxygen-enriched air, and adding concentration is 10wt% and the weight ratio of raw material is 100:5 P 2 o 3 , so that it is fully mixed with the material; when the volume of the raw material reaches 75% of the volume of the oxidation kettle, stop feeding, stop feeding the oxygen-enriched air when the pressure reaches 0.1Mpa, start to heat up, and the temperature rises from room temperature to 145 within 5 minutes ℃, the pressure is controlled at 0.5Mpa, heat preservation and pressure holding for 12 minutes, and the starches ar...

Embodiment 2

[0023] Embodiment 2: The raw material is 100wt% domestic waste. Take the organic matter in the household garbage and put it into the oxidation kettle. When the raw material enters the oxidation kettle, the oxygen-enriched air preheated to 50°C is introduced into the oxygen-enriched air, and the concentration of 6wt% P 2 o 3 , so that it is fully mixed with the material; the P 2 o 3 The weight ratio with the raw material is 100:4; the volume percentage of oxygen in the oxygen-enriched air is 25%;

[0024] When the raw material volume reaches 80% of the oxidation kettle volume, stop feeding, stop feeding the oxygen-enriched air when the pressure reaches 0.2Mpa, start to heat up, the temperature rises to 145°C from room temperature in 5 minutes, and the pressure control is 0.6Mpa, After heat preservation and pressure for 12 minutes, the starches are degraded; then continue to heat up from 145°C to 205°C within 5 minutes, the pressure is controlled to 1.0Mpa, heat preservation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com