Single-electrical signal-stimulated rotation ultrasonic motor

An ultrasonic motor, single electrical signal technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. problems, to achieve the effect of reducing installation requirements, reducing control difficulty, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

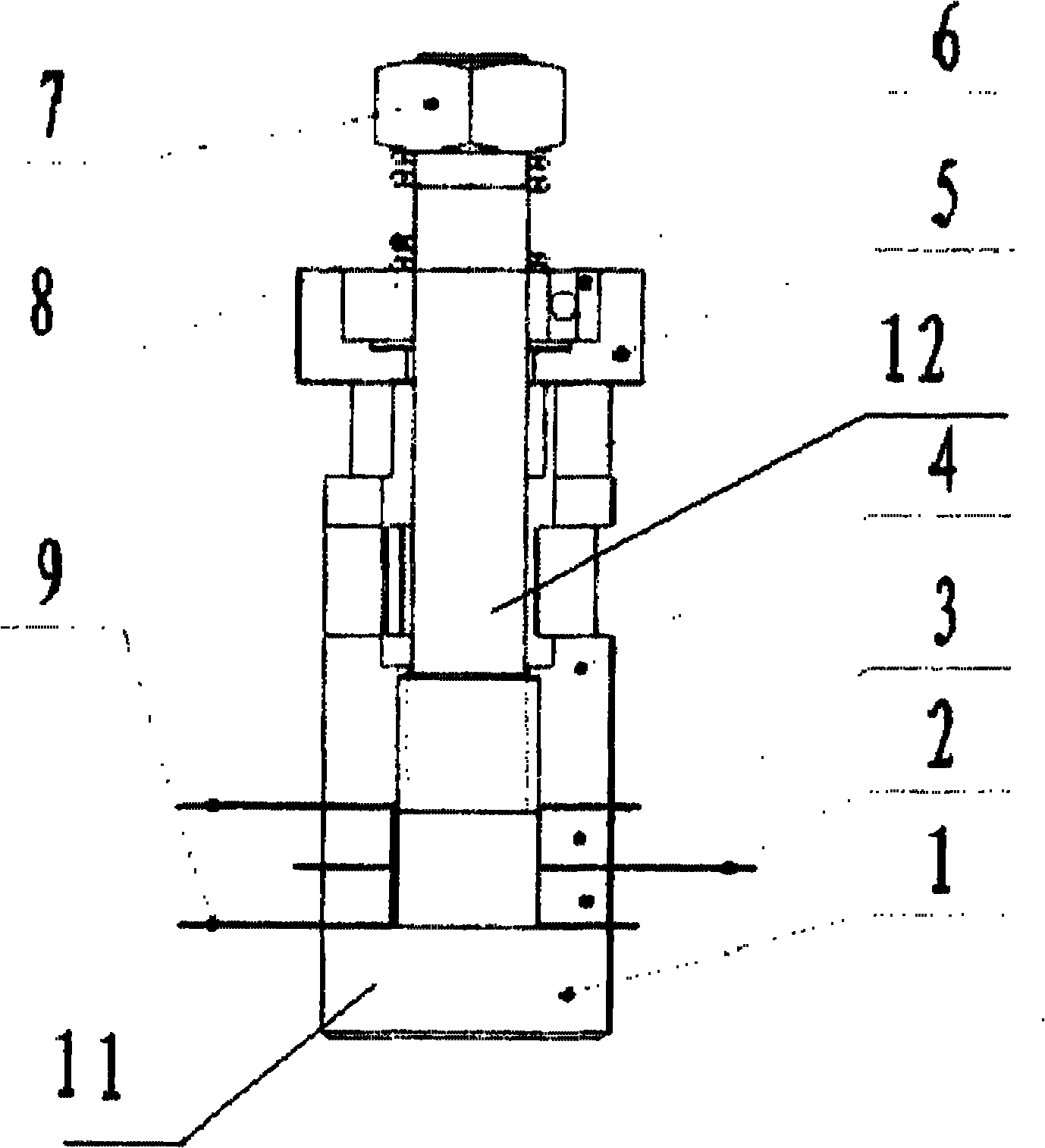

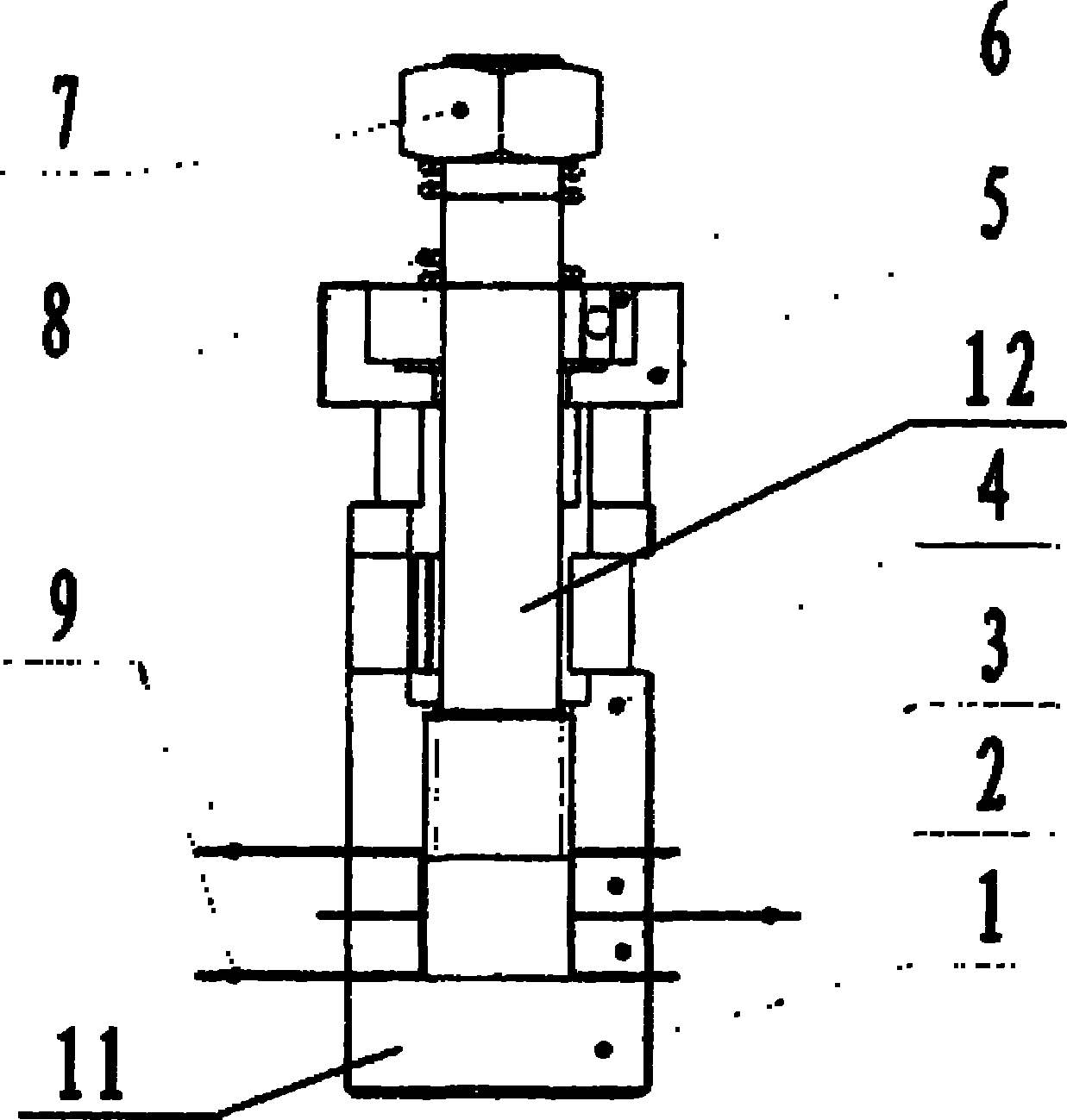

[0023] Such as figure 1 As shown, the ultrasonic motor excited by a single electric signal of the present invention includes a mandrel 1 and a group of piezoelectric ceramic sheets 3, a window-shaped dislocation mode converter 4, a friction disc 5, a bearing 6, The spring 8 and the nut 7, the piezoelectric ceramic sheet 3 are connected with the electrode sheets 2 and 9, the mandrel 1, the piezoelectric ceramic sheet 3, the electrode sheets 2 and 9, and the window-shaped dislocation mode converter 4 constitute the stator part of the ultrasonic motor , The friction disc 5 and the bearing 6 constitute the rotor part of the ultrasonic motor, and the spring 8 and the nut 7 constitute the positive pressure preload adjustment mechanism of the rotor and the stator part of the ultrasonic motor.

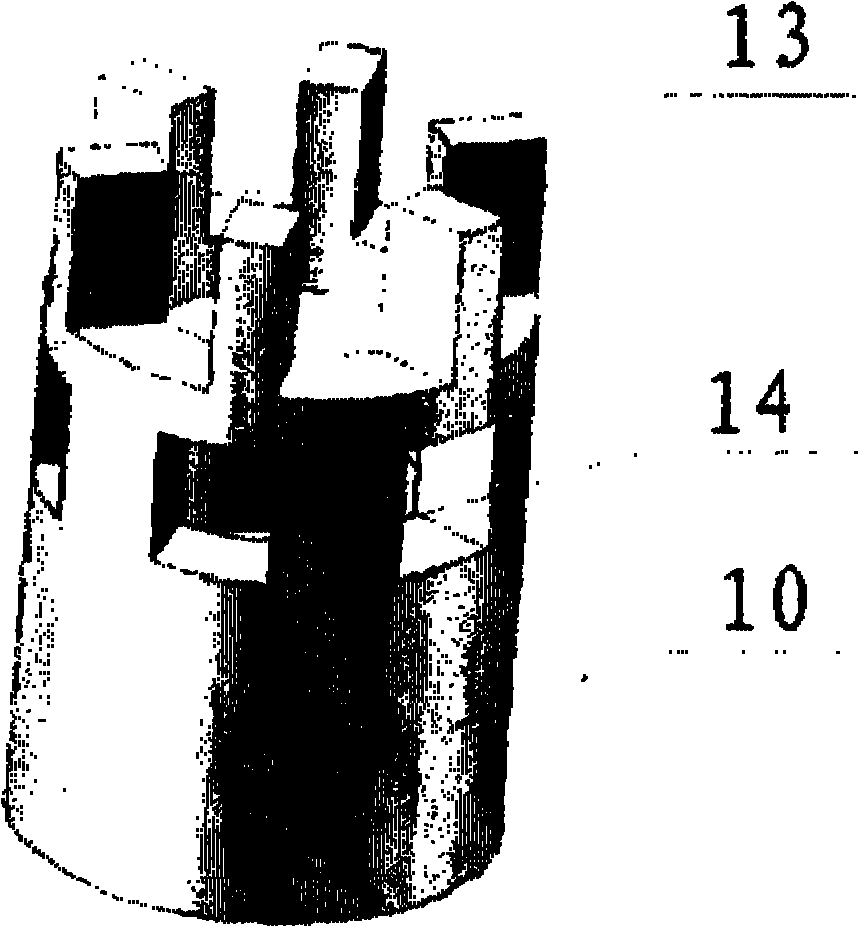

[0024] Wherein, the window-shaped dislocation mode converter 4 is composed of two parts: a lower cylinder part 10 and an upper window-shaped dislocation part, wherein the window-shaped disloca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com