Block type polymer dispersant and preparation method thereof

A block type polymer and block polymer technology, which is applied in the treatment of dyed polymer organic compounds, chemical instruments and methods, fibrous fillers, etc., can solve the adverse effects of paint film appearance, hardness and aging resistance, etc. Poor stability and other problems, to achieve the effect of shortening grinding time, preventing pigment flocculation and precipitation, and increasing transparency and covering power

Inactive Publication Date: 2010-10-20

NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

View PDF4 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When using traditional small molecule dispersants, the stability of the system is poor, and it also has adverse effects on the appearance, hardness and aging resistance of the paint film.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

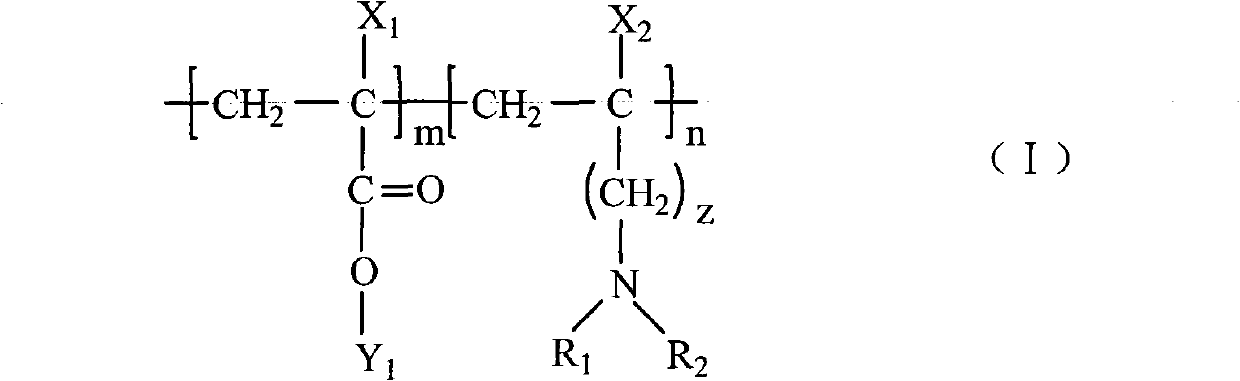

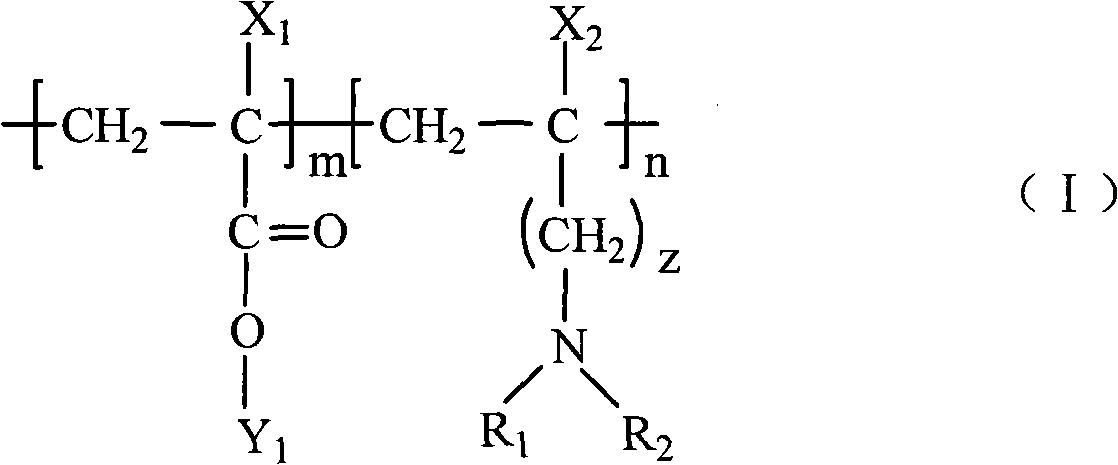

The invention discloses a block polymer dispersant and a preparation method thereof. The structure of the block polymer dispersant is shown in the following formula (I). The invention also discloses a synthesis method for preparing the block type polymer dispersant by single electron transfer / living radical polymerization. The invention has the following advantages: 1) the block type polymer dispersant prepared by the single electron transfer / living radical polymerization is light in color and nearly colorless, can be directly for use, and has a simple synthesis process; 2) the block type polymer dispersant can quickly humidify the pigment particles and shorten the milling time; 3) the steric effect of the polyitaconate deflocculates the pigment particles, and can prevent the pigment from flocculating and precipitating in the storage process; and 4) the deflocculated pigment particles are small, thereby achieving high glaze and color intensity, and increasing transparency and hiding power.

Description

technical field The invention relates to a novel pigment polymer dispersant, and also relates to a preparation method of the dispersant. Background technique In coatings, inks and other industries, the dispersion of pigments is an important part of manufacturing technology. Pigments form solid-liquid dispersions in paints and inks. The dispersion system is thermodynamically unstable, and aggregation may occur during paint making, storage, construction and application, and even film formation. In order to obtain a uniform and stable dispersion, it is often necessary to use a dispersant. When using traditional small molecule dispersants, the stability of the system is poor, and it also has adverse effects on the appearance, hardness and aging resistance of the paint film. In recent years, polymer dispersants have become a new generation of high-efficiency dispersants, which have a significant effect on the dispersion of pigments, especially on wettability and stability, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01F17/52B01F17/36B01F17/16C08F297/06C09C3/10C09C1/00C09C1/56C09B67/20C09K23/52C09K23/16C09K23/36

CPCC08F293/005C08F2438/01

Inventor 张方志

Owner NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com