Laser trimming method of zeropoint resistor of pressure chip of ceramic pressure sensor

A pressure sensor and pressure technology, applied in the field of sensors, can solve problems such as poor precision, low yield, and low efficiency, and achieve the effects of cost reduction, production efficiency improvement, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] like figure 1 , 2 shown.

[0023] A laser trimming method for the zero resistance of a pressure chip of a ceramic pressure sensor, comprising the following steps:

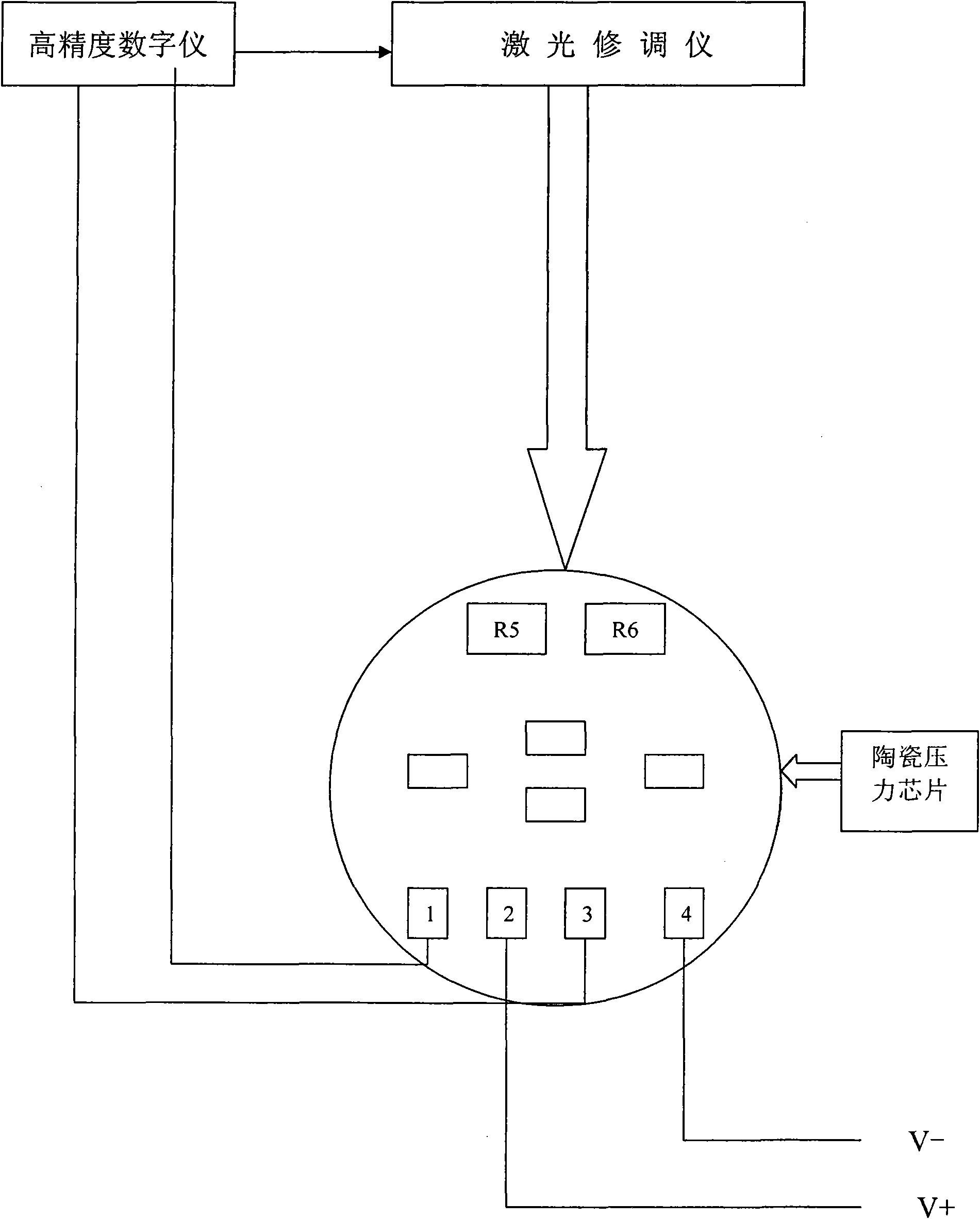

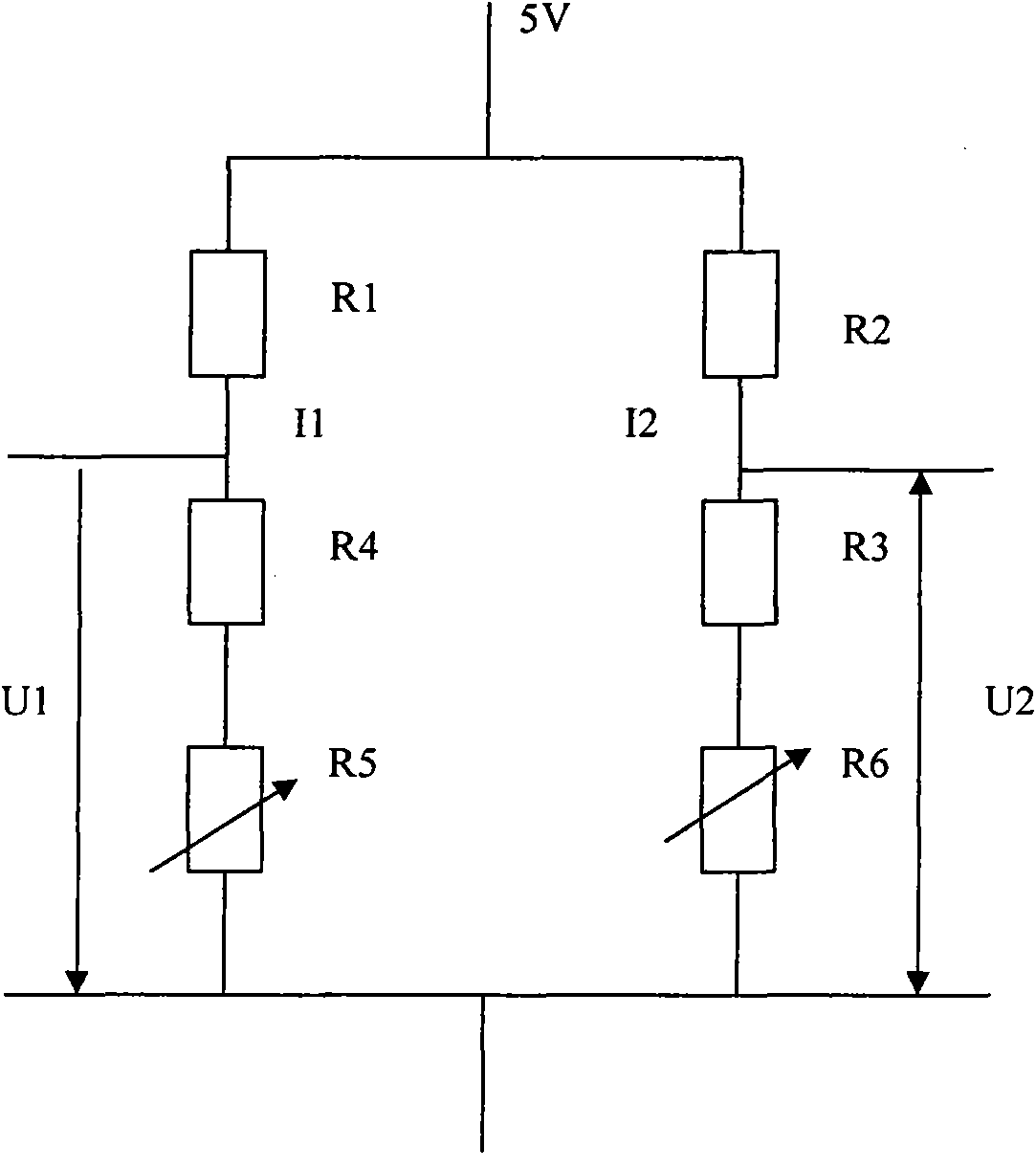

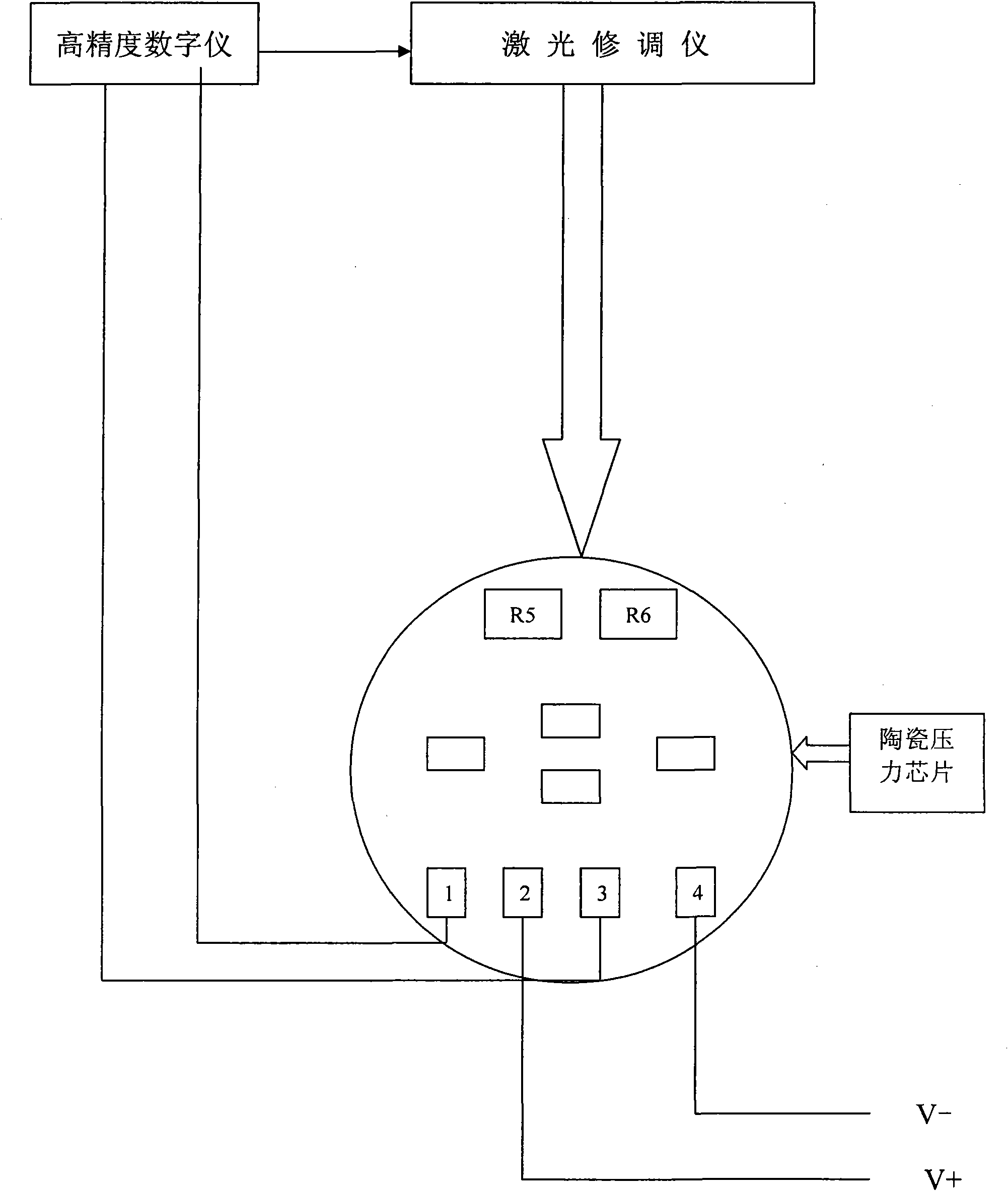

[0024] First, connect a trimmable resistor in series to each of the two bridge arms of the Wheatstone bridge; and press figure 1 The ceramic pressure chip, high-precision digital voltmeter and laser trimmer are connected as shown in the figure. In actual implementation, special tooling can be designed to position the ceramic pressure chip, and each measurement point is also connected by pressure contact contacts; Resistors R1 and R4 form a bridge, an adjustable resistor R5 is connected in series on one side of the resistor R4, and another bridge is formed by resistors R2 and R3, and an adjustable resistor R6 is connected in series on the side of the resistor R3, as figure 2 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com