Method for connecting and positioning column and carriage of machine tool

A sliding seat and column technology, which is applied in the field of connection and positioning between the mobile column and the sliding seat of large CNC machine tools, can solve the problems of reducing the stability and rigidity of the machine tool, long production cycle of the machine tool, time-consuming and labor-intensive, etc., to reduce the difficulty of processing , Improve production stability, cancel the effect of scraping and grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

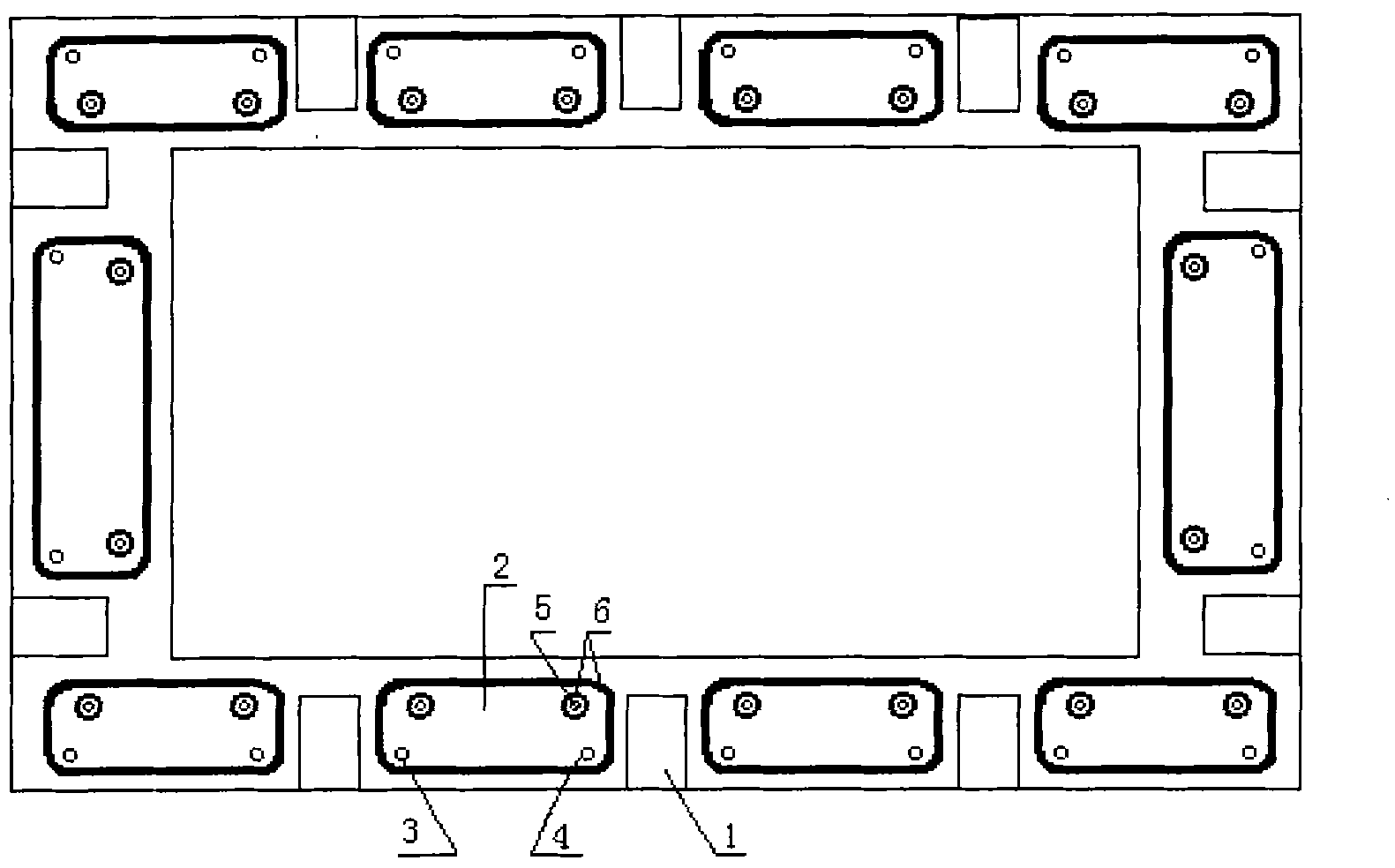

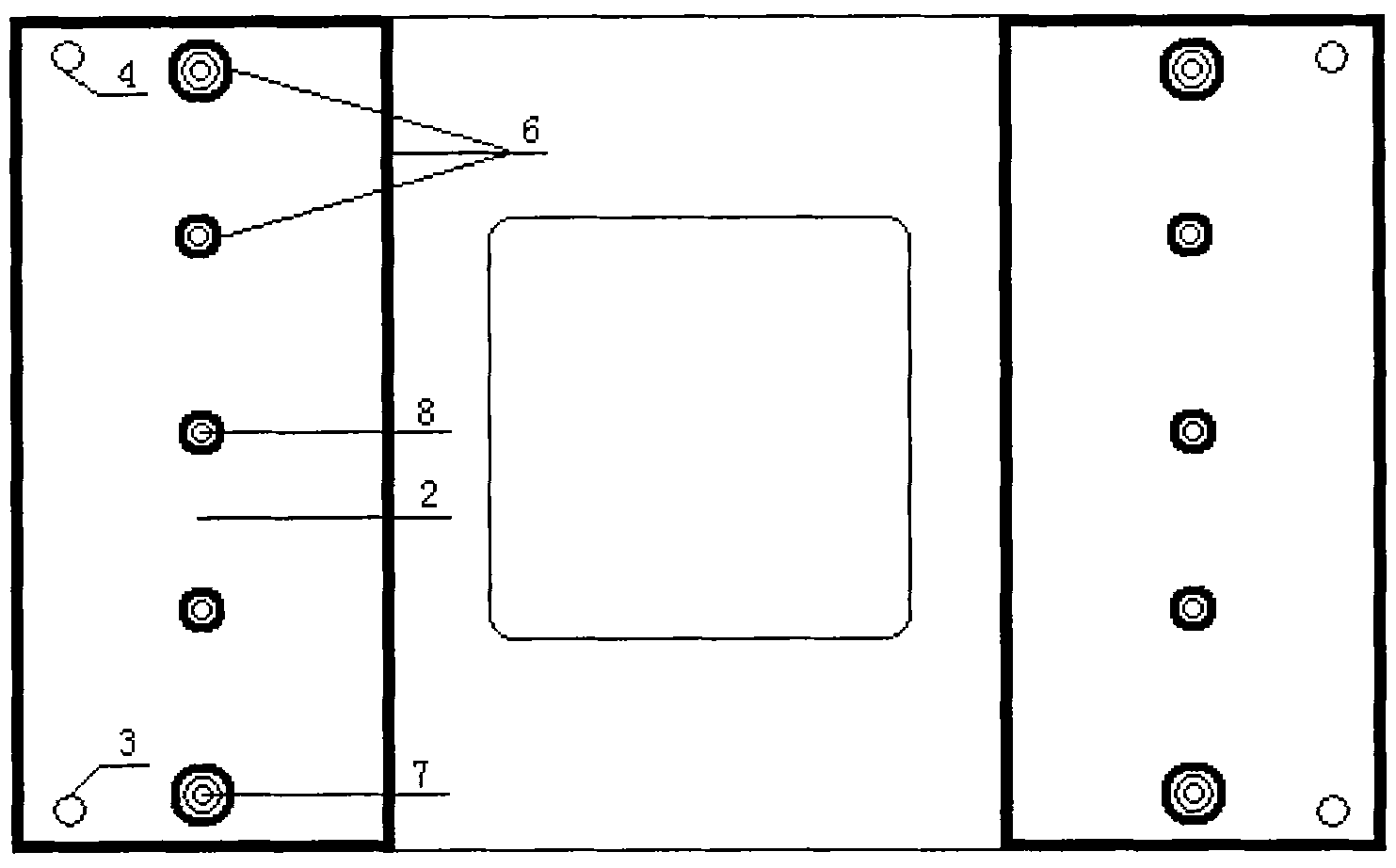

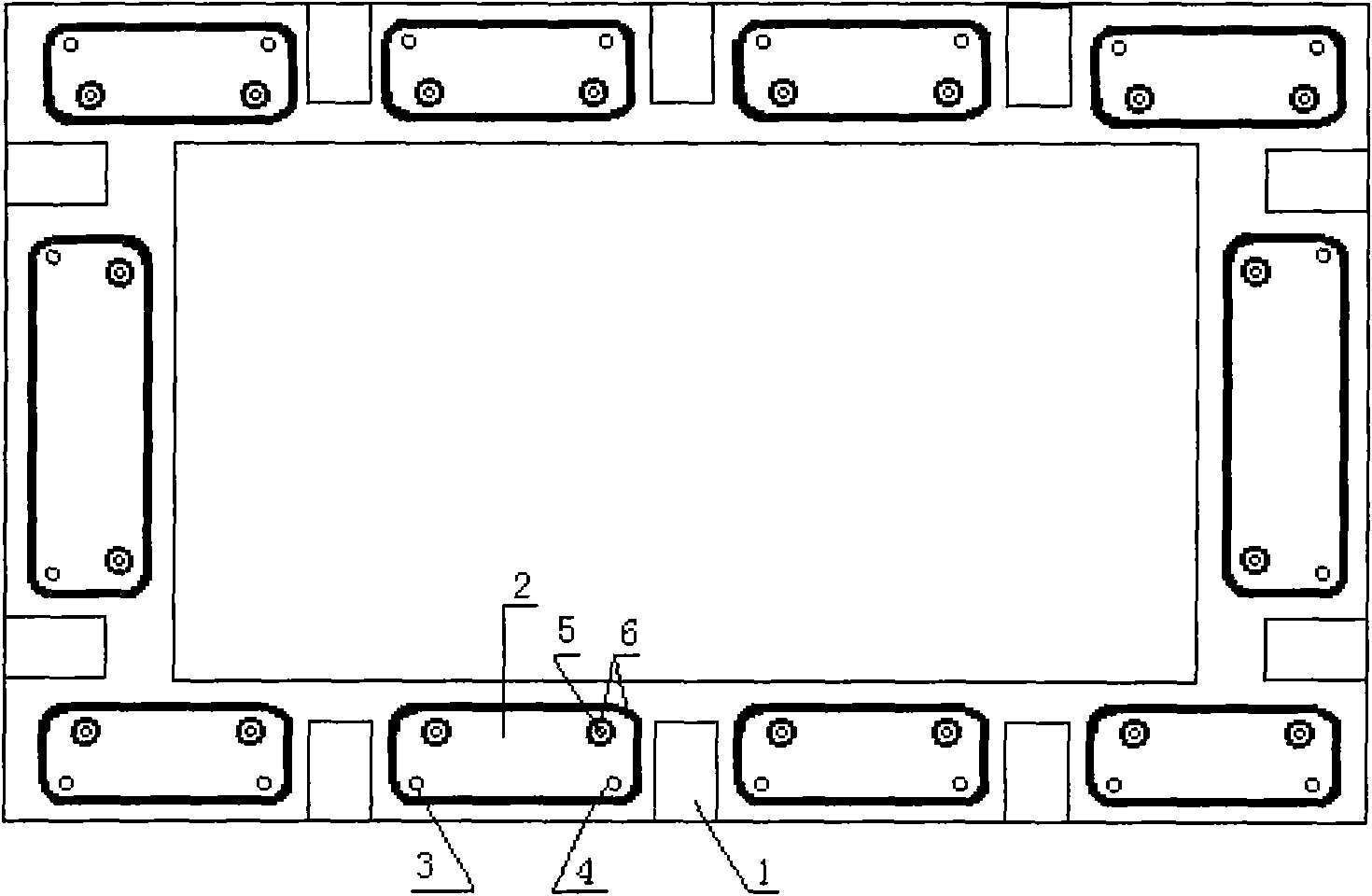

[0016] The present invention will be further described below in conjunction with the accompanying drawings: the method for connecting and positioning the column of the machine tool and the sliding seat is to properly process several injection chambers 2 on one side of the column of the machine tool. The glue hole 3 and the glue outlet hole 4; between the glue injection chamber 2, place and adjust the position of the wedge iron 1 properly. Before the column is connected with the sliding seat, clean the inside of the glue injection cavity with a cleaning agent, such as acetone, trichlorethylene, etc. If you want to facilitate disassembly, you can spray or wipe the release agent on the surface where the sliding seat and the column are fastened. Use EPDM foamed rubber strips (oil-resistant foamed rubber) or foamed plastics of appropriate width as the sealing strip 6, and glue a circle around the inside of the injection cavity. Instant adhesive can be used for bonding. The sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com