Filter back washing water recovery processing method and membrane filtration system thereof

A technology for backwashing water and recycling treatment, which is applied in the fields of water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing water purification load, stabilizing water quality, and improving water quality safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described below in conjunction with embodiment:

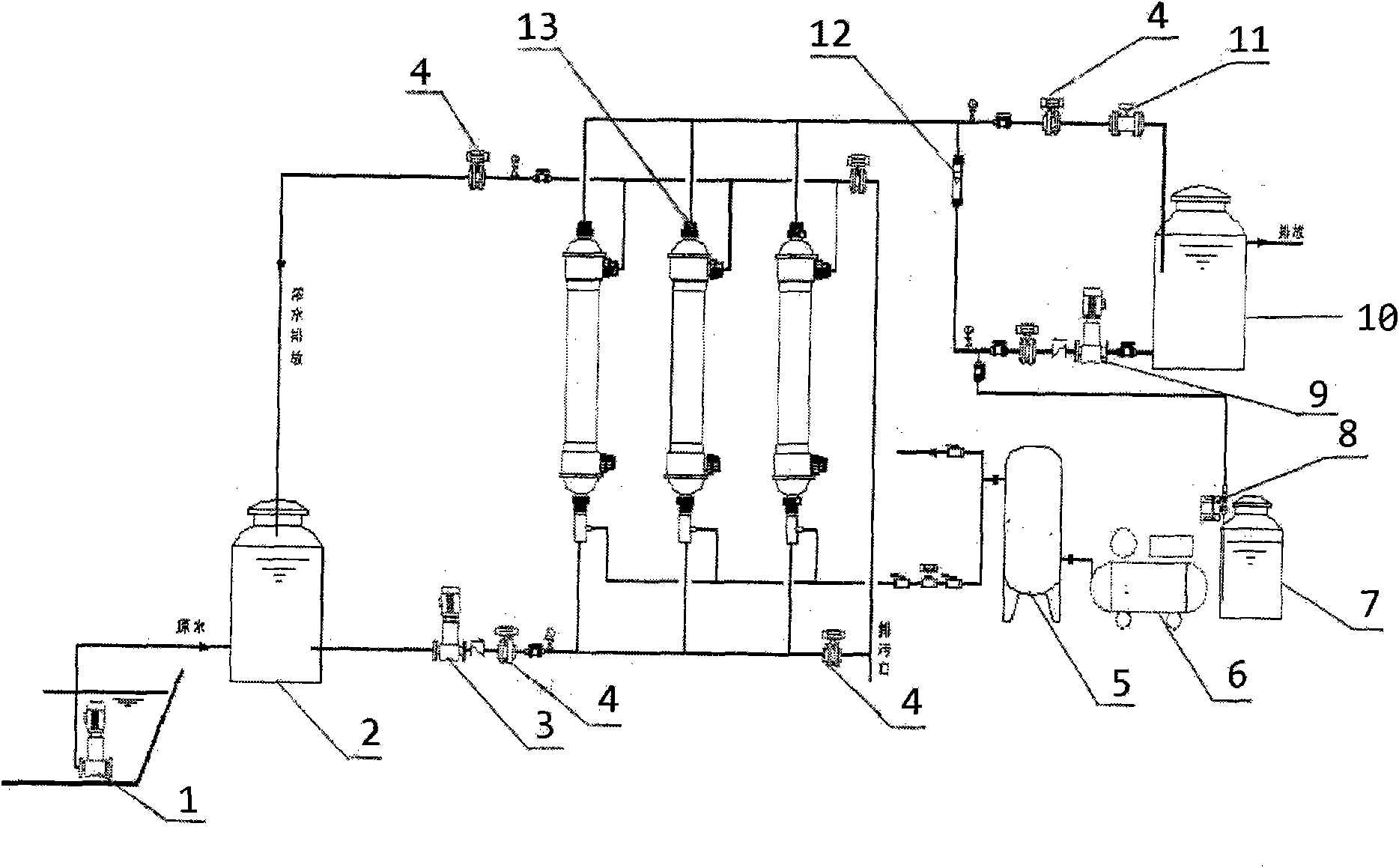

[0023] The method for recovering and treating backwash water in a filter tank of the present invention includes A: a pretreatment process, B: a membrane filtration process, and C: a disinfection process.

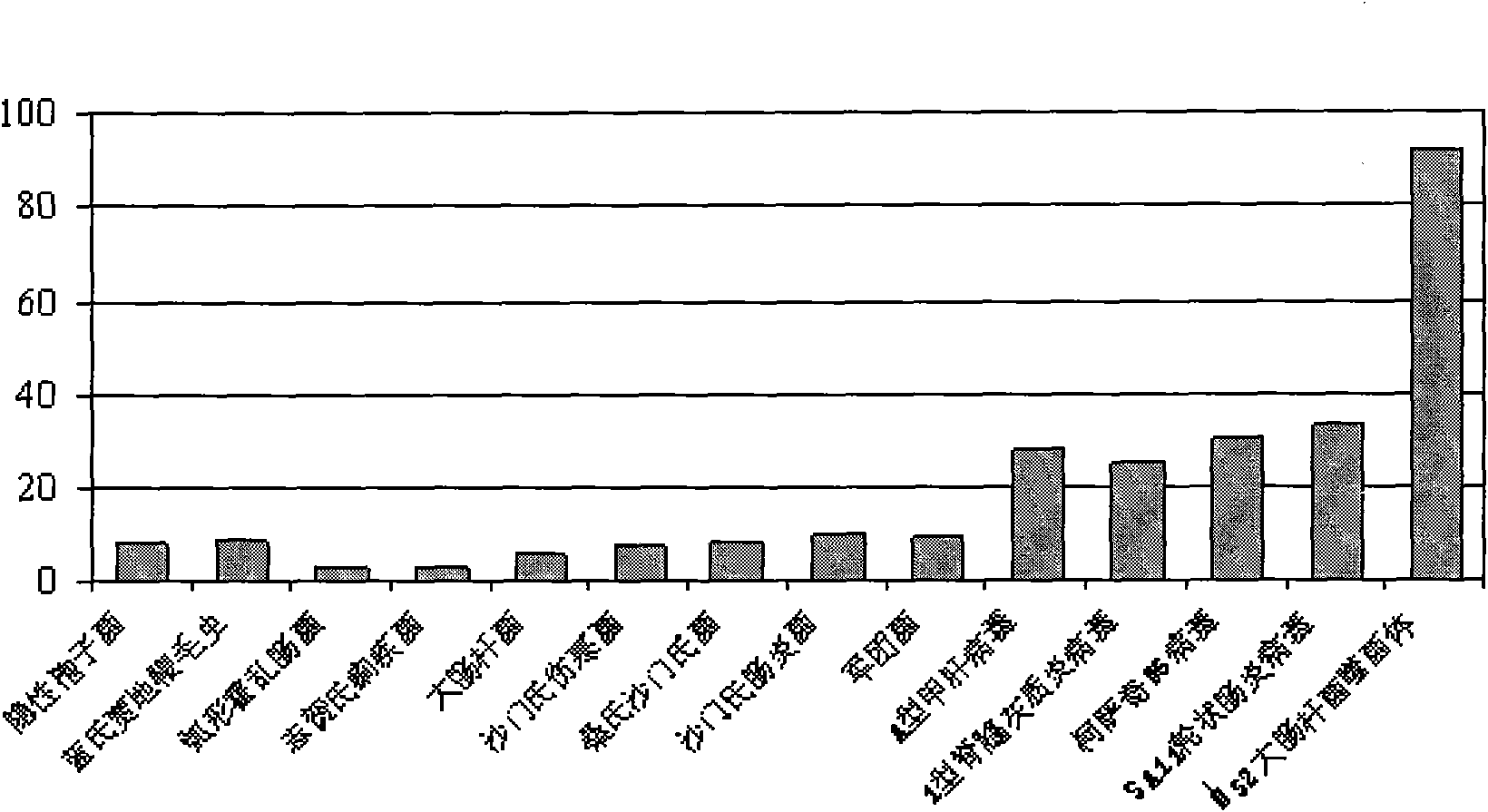

[0024] The A: The purpose of the pretreatment process is to remove particulate matter and reduce the load of pollutants entering subsequent units. It can be used in both batch recovery and continuous recovery. The more commonly used methods are sedimentation, micro-sand assisted sedimentation or air flotation. The pretreatment process can be used alone, but when the sedimentation effect is not good when used alone, a coagulant can be added during the pretreatment, the purpose of which is to help improve the separation effect. It has been proved that the proper application of pretreatment can obtain satisfactory turbidity and particle removal rate, including two insects. The preferred coagulan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com