Preparation method of composite strengthening anti-cracking cloth

A composite reinforcement and anti-cracking technology, which is applied in the direction of road building reinforcements, textiles, papermaking, braids, etc., can solve the problem that the combination performance of the grid and the road surface is not very ideal, it cannot effectively prevent water penetration, and it cannot be continuously waterproofed Layer and other problems, to prevent reflective cracks and water damage, improve the overall strength value, prevent and delay other cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

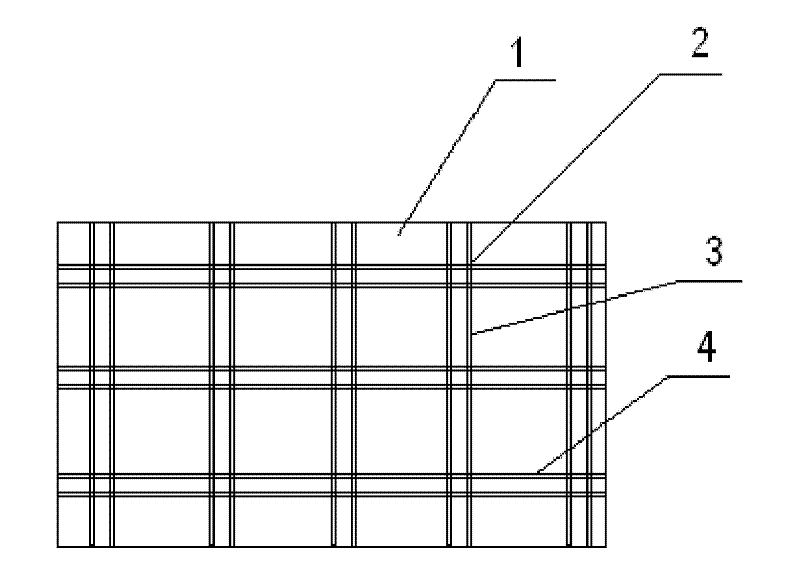

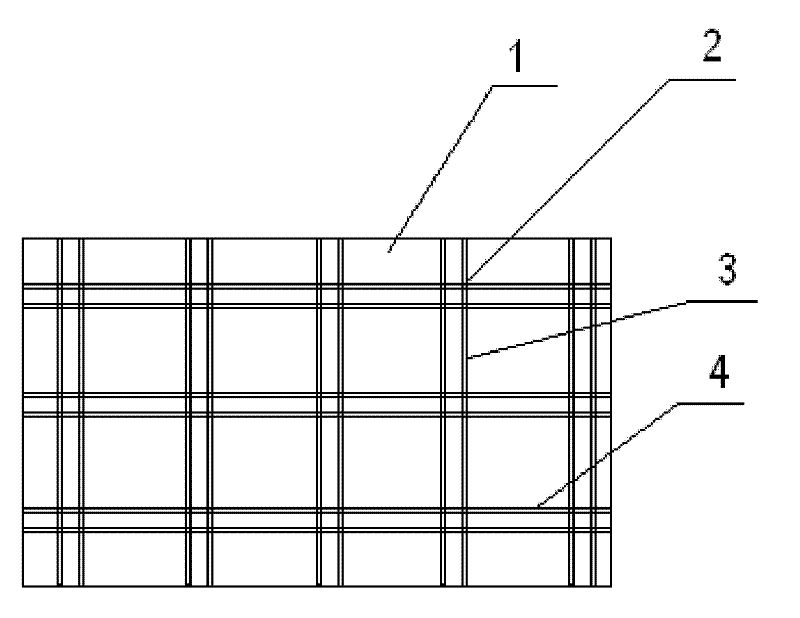

[0049] Such as figure 1 As shown, the composite reinforced anti-crack cloth is composed of a geotextile 1 and a glass fiber geogrid 2 through warp knitting, the geotextile 1 is a glass fiber polyester anti-crack cloth, and the glass fiber polyester anti-crack cloth The gram weight is 120g / m 2 , the thickness is 0.66~0.68mm, the mass ratio of polyester fiber and glass fiber in the glass fiber polyester anti-crack cloth is 30:70, the density of warp yarn 3 of glass fiber geogrid is 2 / mesh, weft yarn 4 The density is 2 / mesh. The linear density of the binding yarn used in weaving is 220dtex, the distance per circle is 4.23mm, and the strength of warp yarn 3 and weft yarn 4 is 0.41N / tex. The knitting is a warp knitting method.

[0050] Tested according to the standard "SL / T-235-1999", the weight per unit area of the obtained composite reinforced anti-cracking cloth is 375g / m 2 , the longitudinal breaking strength reaches 53KN / m, the transverse breaking strength reaches 51KN / m...

Embodiment 2

[0052] The composite reinforced anti-cracking cloth described in Example 1 was dipped in the modified asphalt solution in which No. AH-70 road petroleum asphalt and water were uniformly mixed in a mass ratio of 1:20, and then dried in an oven. The oven is divided into four areas: A, B, C, and D, and the temperatures are set at 100°C, 105°C, 120°C, and 130°C, respectively. Before impregnation, the composite reinforced anti-cracking cloth should be smooth and wrinkle-free.

[0053] According to the standard "SL / T-235-1999", the mass per unit area of the composite reinforced anti-cracking cloth obtained after impregnation and drying is 390-400g / m 2 , the longitudinal breaking strength reaches 55-58KN / m, the transverse breaking strength reaches 53-55KN / m; the longitudinal and transverse breaking elongation is 1.9-2.7%, the longitudinal and transverse trapezoidal tear strength is 1000N, and the CBR bursting strength reaches 3.5KN. This product has been used in Quanxia Expressway...

Embodiment 3

[0055] The composite reinforced anti-crack cloth is composed of geotextile 1 and glass fiber geogrid 2 through warp knitting, the geotextile 1 is a glass fiber polyester anti-crack cloth, and the weight of the glass fiber polyester anti-crack cloth is 160g / m 2 , the thickness is 1.0~1.08mm, the mass ratio of polyester fiber and glass fiber in the glass fiber polyester anti-crack cloth is 25:75, the density of warp yarn 3 of glass fiber geogrid is 2 / mesh, weft yarn 4 The density is 2 / mesh. The linear density of the binding yarn adopted during weaving is 170dtex, the distance per circle is 4.23mm, and the strength of warp yarn 3 and weft yarn 4 is 0.50N / tex. The knitting is a warp knitting method. The composite reinforced anti-crack cloth obtained by weaving is dipped in the modified asphalt solution mixed uniformly with AH-70 road petroleum asphalt and water at a mass ratio of 1:15, and then dried in an oven. The oven is divided into four areas: A, B, C, and D, and the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com