High-precision surface evening method for large-sized high-bearing capability steel structure slideways

A steel structure, large-scale technology, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of high construction cost, high cost, unsuitable leveling, etc., and achieve low material and personnel investment, high compressive strength, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

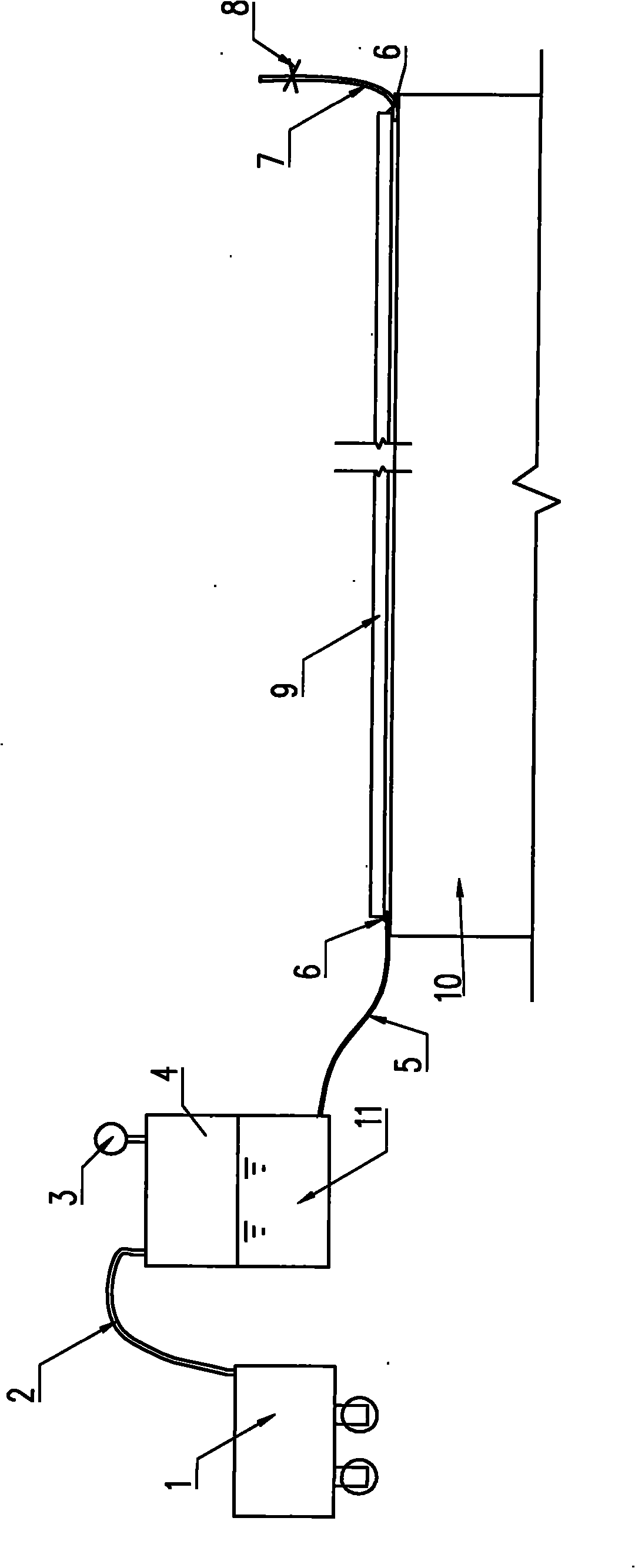

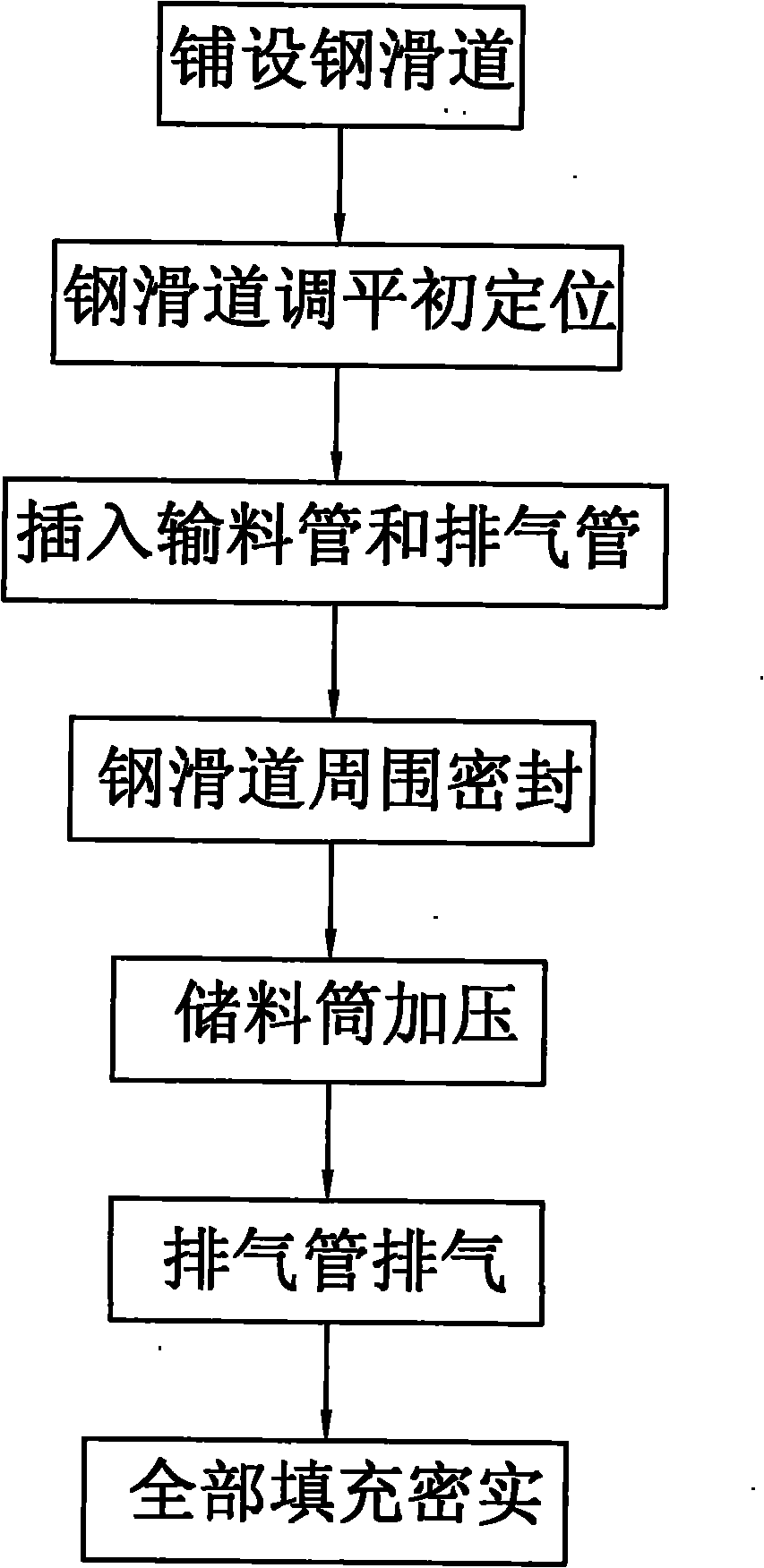

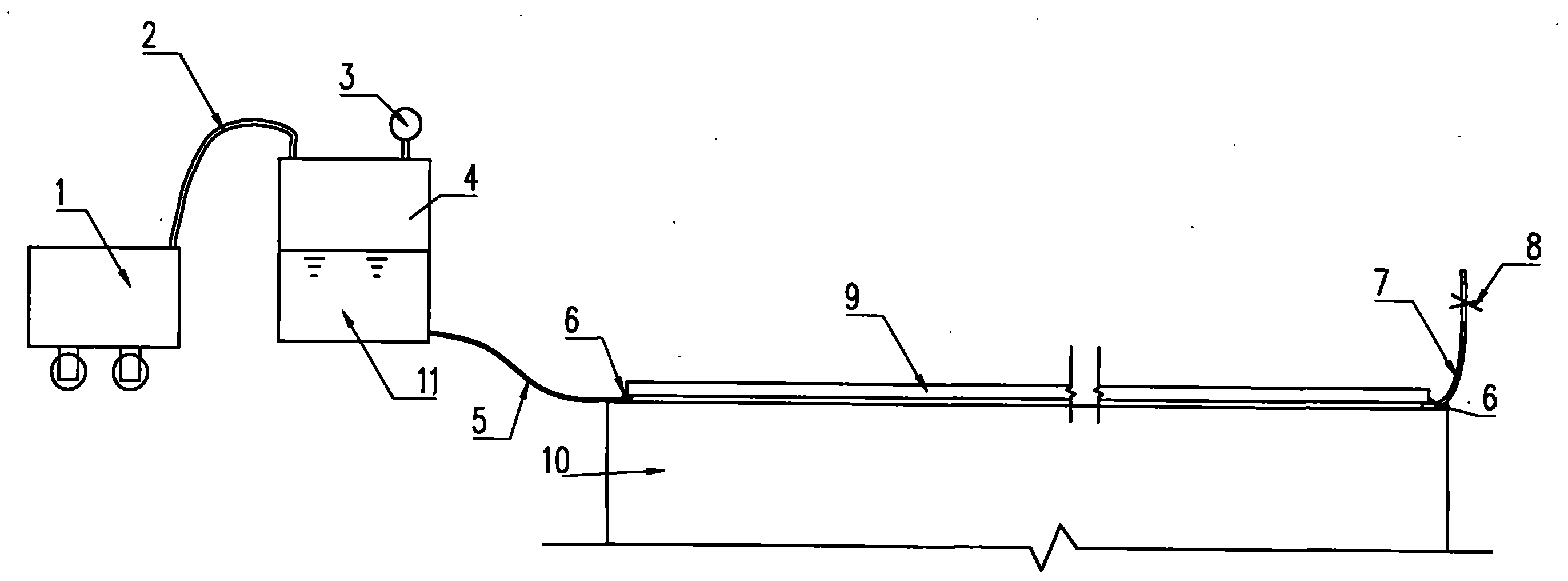

[0019] figure 2 For the construction flowchart of the present invention, in conjunction with figure 2 Detailed description of the specific implementation method: a method for high-precision surface leveling of a large-size, high-bearing-capacity steel structure slideway, including the following steps:

[0020] (1) Lay a large-scale steel structure slideway 9 on the installed steel structure slideway beam 10, and measure the flatness of the large-size steel structure slideway 9;

[0021] (2) In the case of a small space under the large-size steel structure slideway 9, according to the measured flatness, use the method of copying the lower part of the large-size steel structure slideway 9 and partially pressurizing the upper part to accurately level the slideway , for initial positioning;

[0022] (3) Insert one end of the feeding pipe 5 and one end of the exhaust pipe 7 respectively under the two ends of the large-size steel structure slideway 9, the discharge pipe 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com