Refrigerator with double capillary tubes and multiple refrigerating loops

A technology of refrigeration circuit and capillary tube, which is applied in the field of refrigerators with double capillary tubes and multiple refrigeration circuits, can solve the problems of low refrigeration efficiency and achieve the effects of increasing refrigerant density, energy efficiency ratio and evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

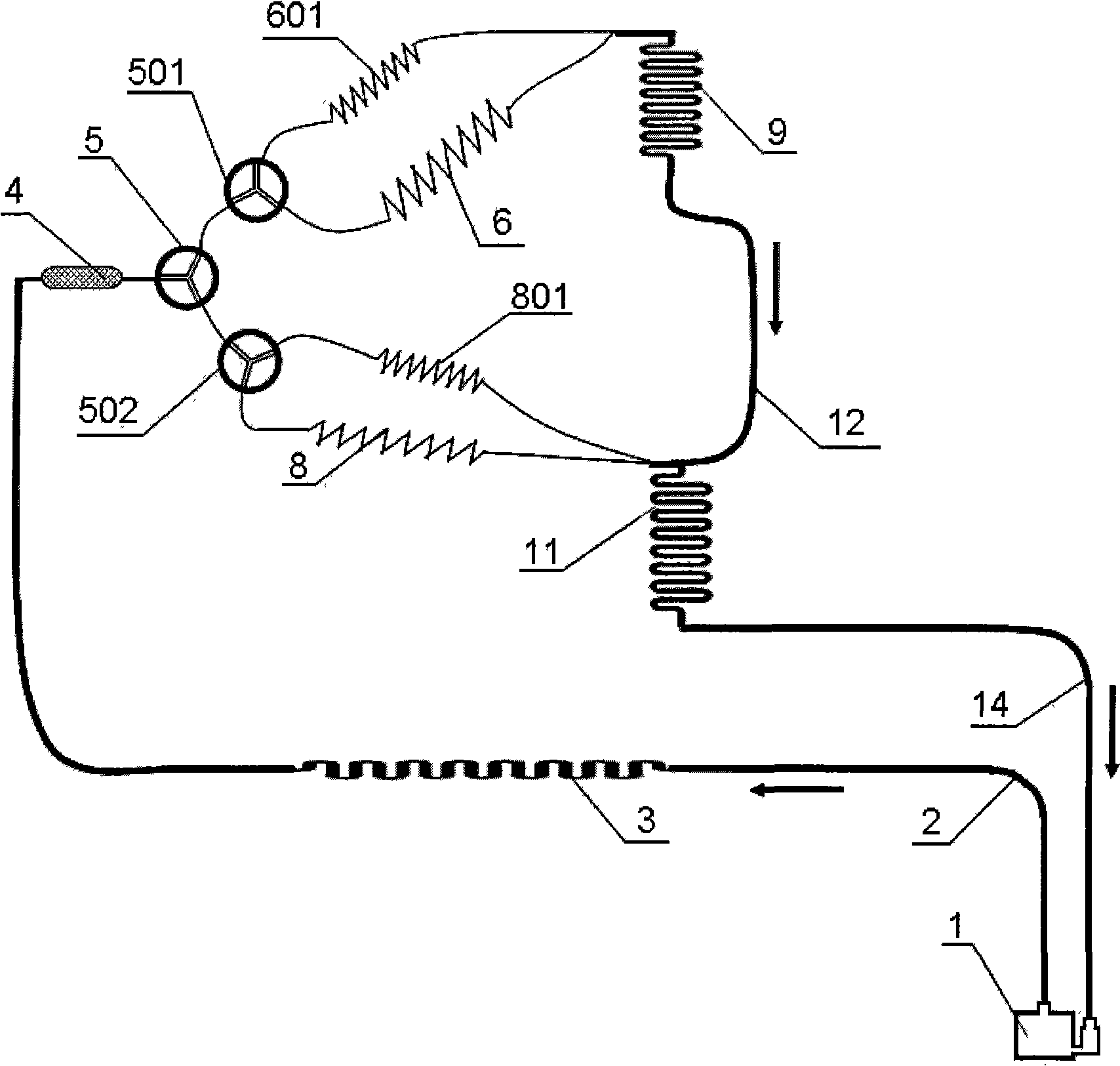

[0032] image 3 It is a schematic diagram of a refrigerator with double capillary tubes and multiple refrigeration circuits in the present invention.

[0033] Such as image 3 As shown, a refrigerator with double capillary tubes and multiple refrigeration circuits of the present invention includes a compressor 1, a compressor exhaust pipe 2, a condenser 3, a dry filter 4, a first two-position three-way solenoid valve 5, a second two-position Three-way solenoid valve 501, third two-position three-way solenoid valve 502, first capillary 6, third capillary 8, fourth capillary 601, sixth capillary 801, refrigerating chamber evaporator 9, freezing chamber evaporator 11, refrigeration- Freezing connection pipe 12, air return pipe 14, program controller (not shown).

[0034] One end of the compressor exhaust pipe 2 is connected to the compressor 1, and the other end is connected to the condenser 3; one end of the dry filter 4 is connected to the condenser 3, and the other end is co...

no. 2 approach

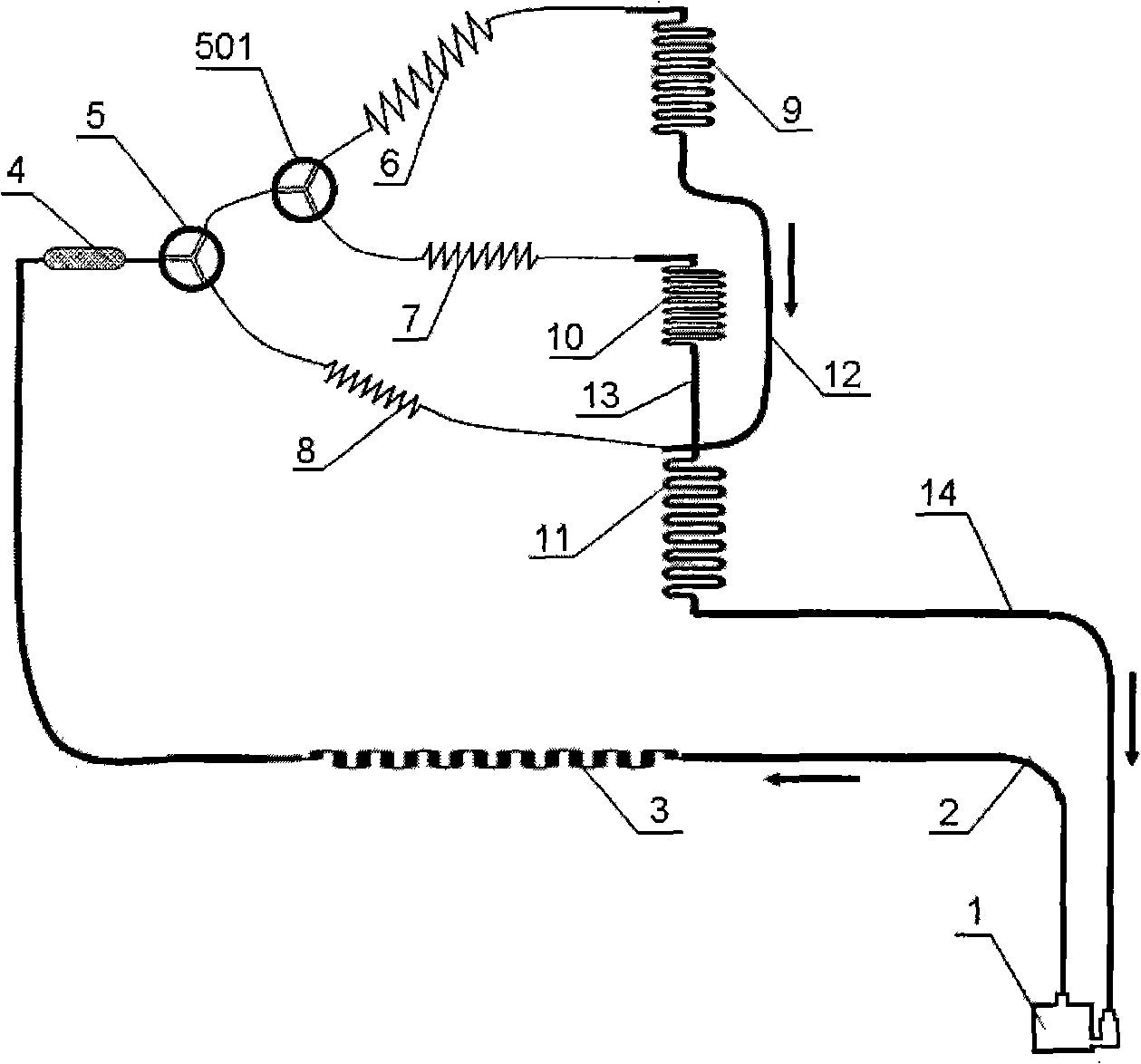

[0043] Figure 4 It is a schematic diagram of the second embodiment of a refrigerator with double capillary tubes and multiple refrigeration circuits in the present invention. The second embodiment is basically the same as the first embodiment, except that the variable temperature chamber evaporator 10, the variable temperature-freezing connecting pipe 13, the fourth two-position three-way solenoid valve 503, the fifth two-position three-way solenoid valve 504, and the second two-position three-way solenoid valve 504 are added. Capillary 7 and fifth capillary 701.

[0044] ① When the refrigerator and freezer are to be refrigerated at the same time, if the temperature detected by the ambient temperature sensor is high, the first two-position three-way solenoid valve 5, the second two-position three-way solenoid valve 501 and the fourth two-position solenoid valve 501 are activated. The three-way solenoid valve 503 is used to connect the first capillary 6 (longer capillary) wit...

no. 3 approach

[0048] Figure 5 It is a schematic diagram of a third embodiment of a refrigerator with double capillary tubes and multiple refrigeration circuits in the present invention. The third embodiment is basically the same as the first embodiment except that a condenser fan 15 is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com