Plane surface shape measurement method of optical fiber point-diffraction phase-shifting interferometer

A point diffraction phase shift and measurement method technology, applied in the field of optical precision measurement, can solve the problems of large additional aberration and affect measurement accuracy, and achieve the effect of reducing aberration and improving the measurement accuracy of plane surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] The method for measuring the plane shape of an optical fiber point diffraction phase-shifting interferometer comprises the following steps:

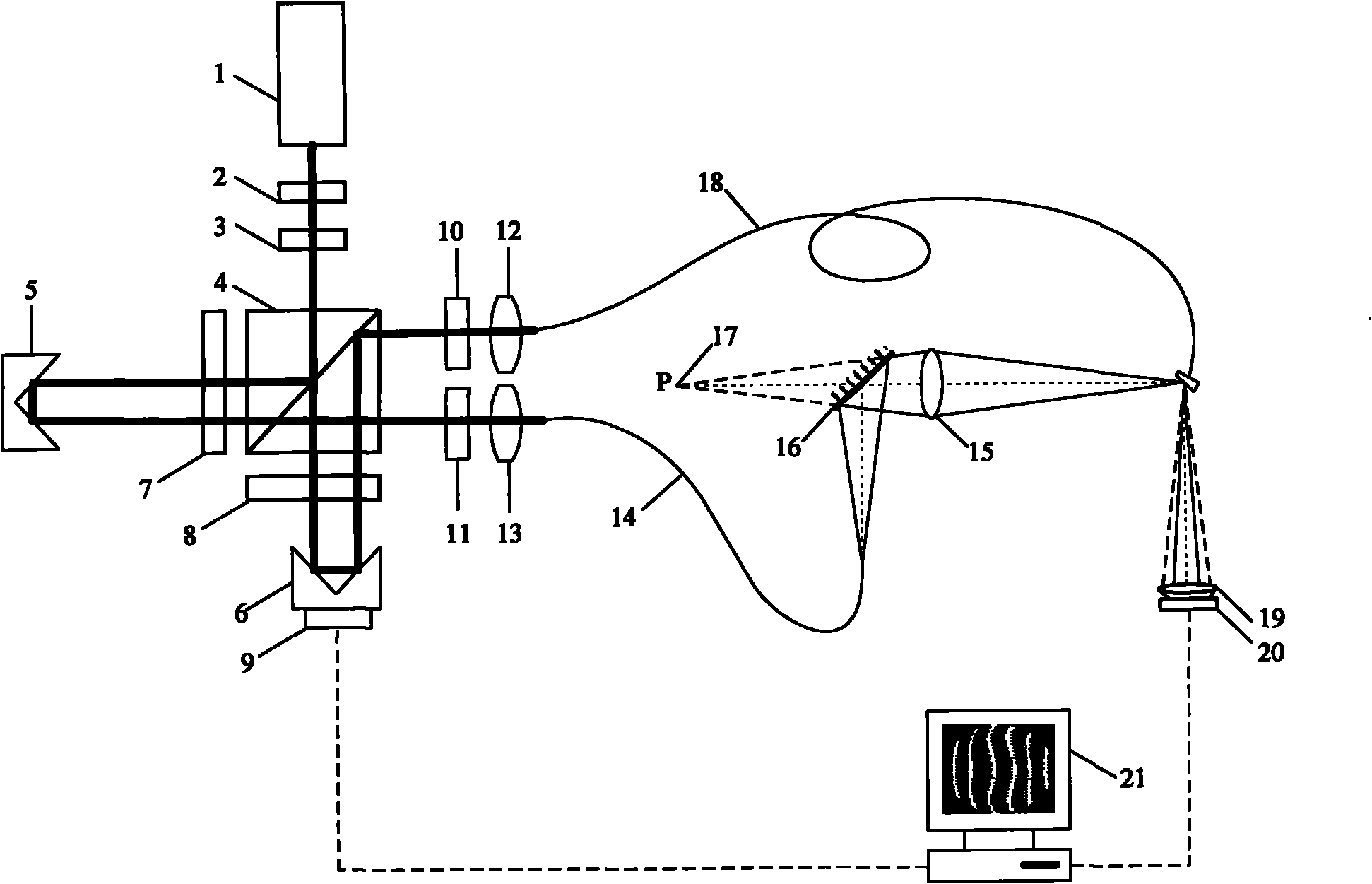

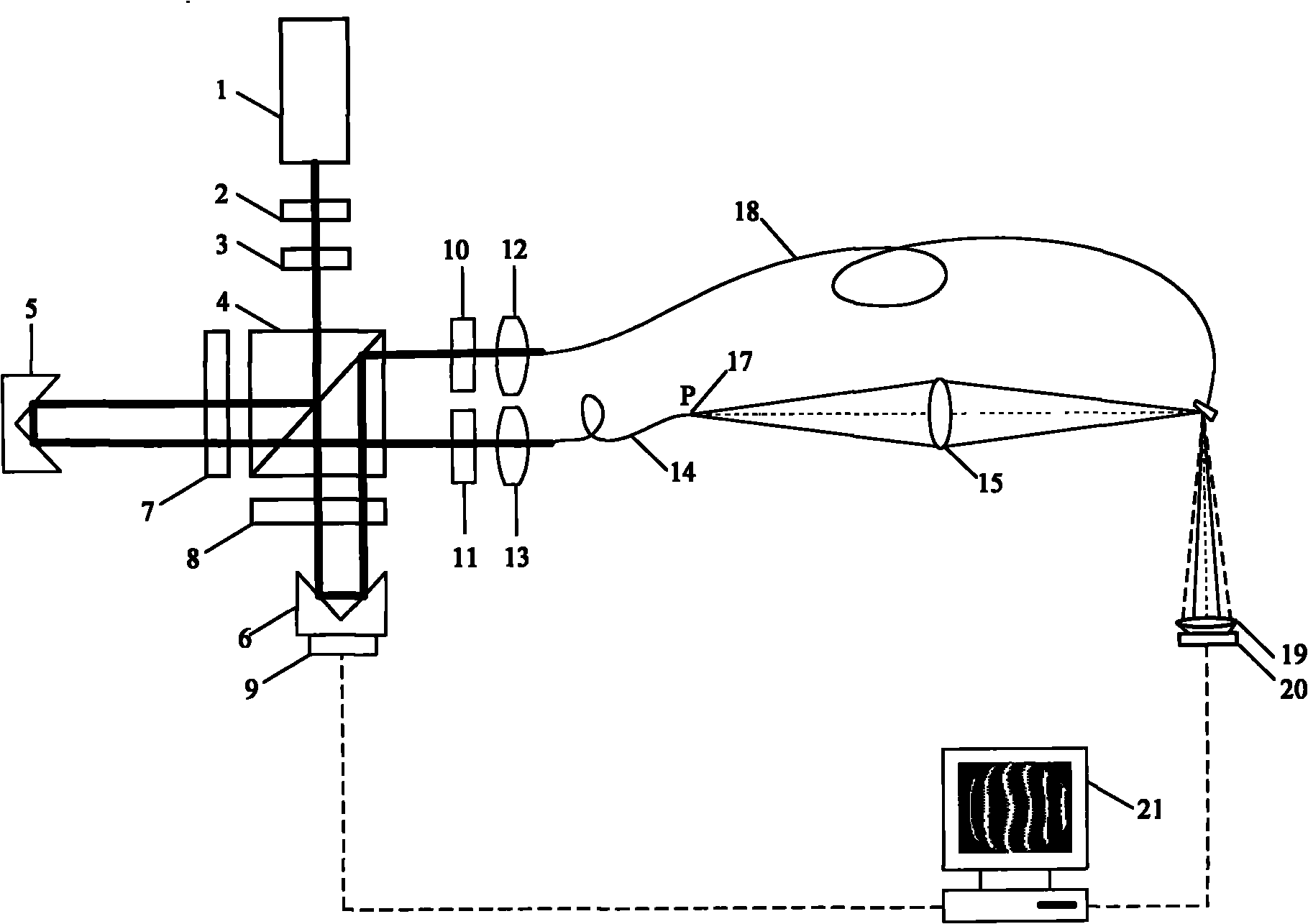

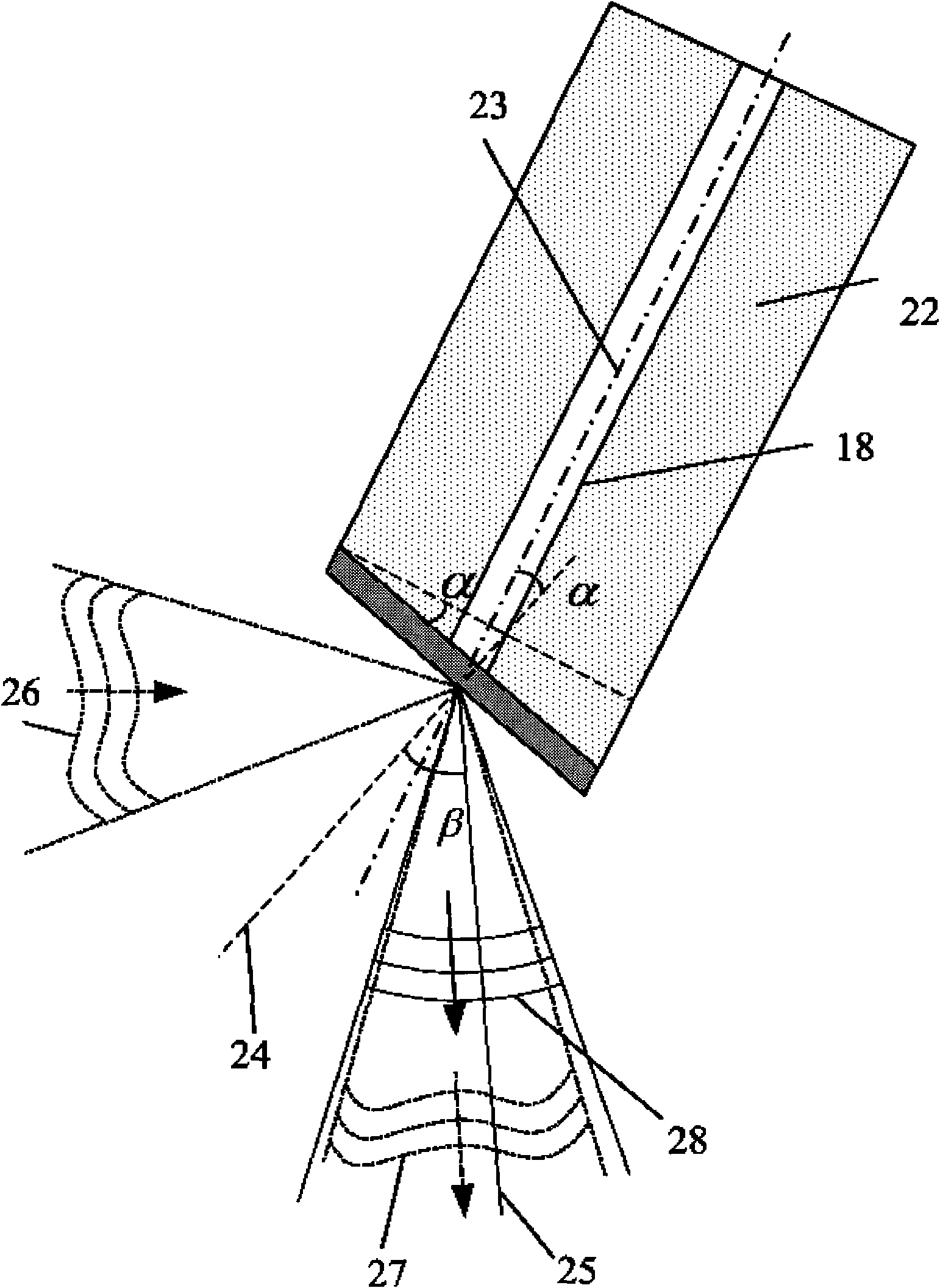

[0031] In the first step, deploy a set of measurement devices, such as figure 1 , figure 2 As shown, it includes: spectroscopic system, measuring optical fiber 14, auxiliary positive lens 15, measured plane mirror 16, reference optical fiber 18, imaging lens 19, CCD camera 20, computer 21;

[0032] Among them, the beam splitting system includes a laser 1, an adjustable neutral density filter 2, a 1 / 2 wave plate 3, a polarizing beam splitting prism 4, a first right-angle prism 5, a second right-angle prism 6, and a first 1 / 4 wave plate 7. The second 1 / 4 wave plate 8 , the piezoelectric ceramic 9 , the first polarizer 10 , the second polarizer 11 , the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com