Vibrating table short circuit ring cooling structure and preparation method thereof

A cooling structure and short-circuit ring technology, which is applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve equipment safety hazards, water leakage and other problems, and achieve low cost, simple processing technology, and high-efficiency cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

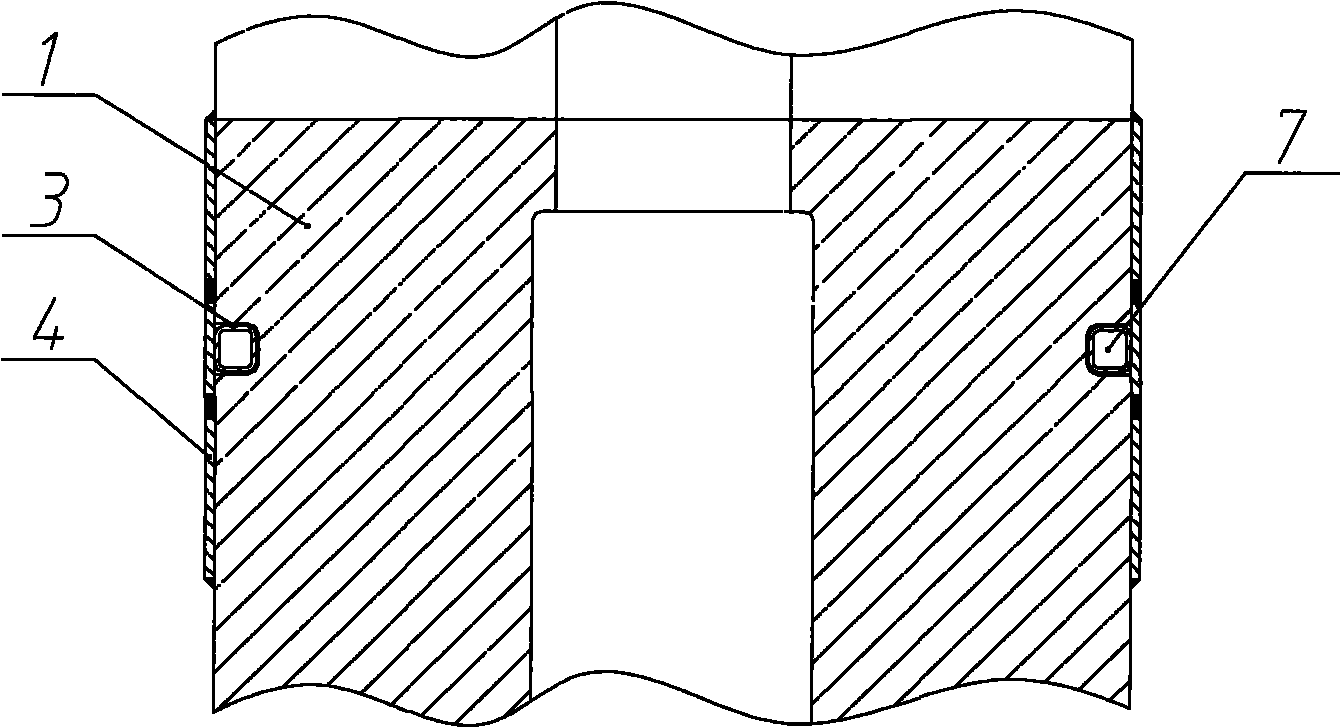

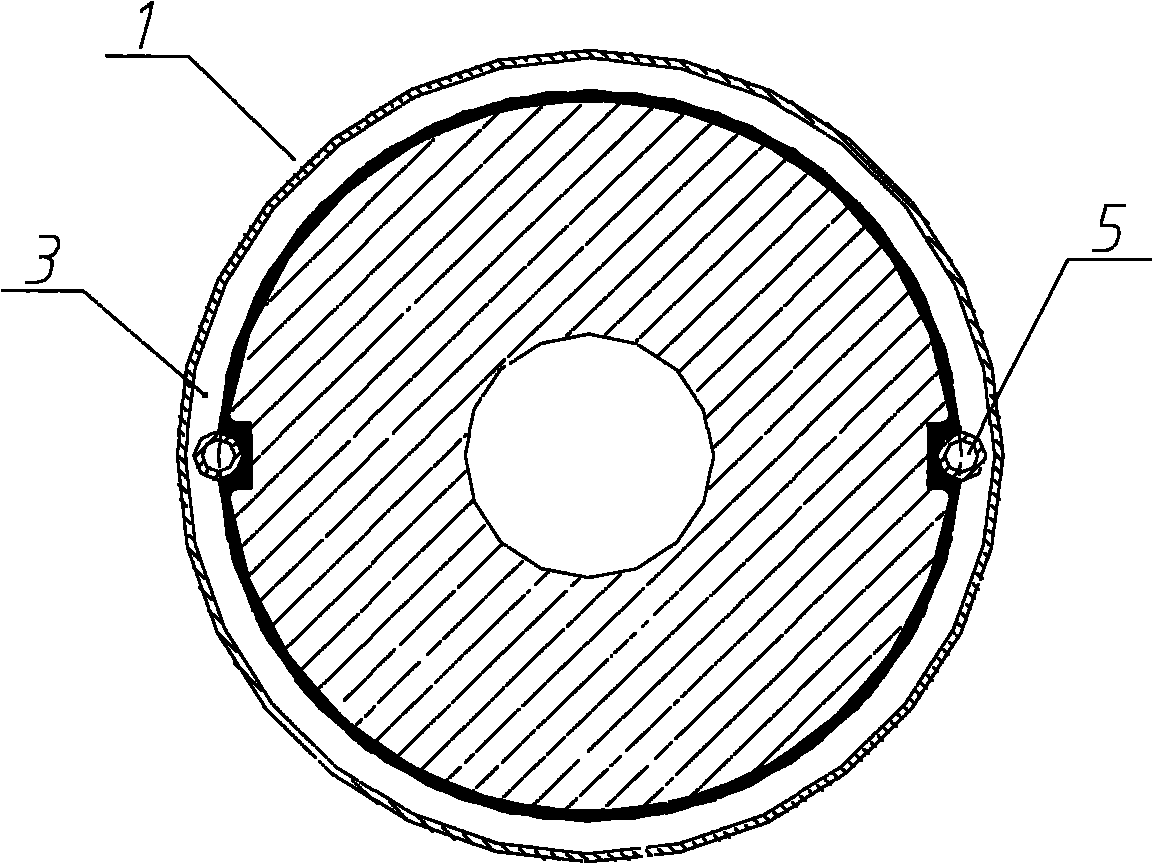

Embodiment 1

[0031] Example 1 as Figure 2~3 As shown, the short-circuit ring cooling structure of the vibrating table includes a short-circuit ring 4 arranged on the central magnetic pole 1. Two deep holes 8 are arranged in the central magnetic pole along the axial direction, and a cooling water pipe 5 with a closed upper end is respectively arranged in the deep holes. , and one of the cooling water pipes communicates with the peripheral cooling water supply equipment to form a water inlet channel, while the other cooling water pipe forms a return water channel, and an annular groove 3 is opened on the outer wall of the central magnetic pole 1, and the two cooling water pipes pass through it. An opening provided on the upper pipe wall communicates with the annular groove 3, and the annular groove wall is fixedly connected with the corresponding cooling water pipe wall by all-copper surfacing welding. The width of the short-circuit ring is greater than that of the annular groove, and the in...

Embodiment 2

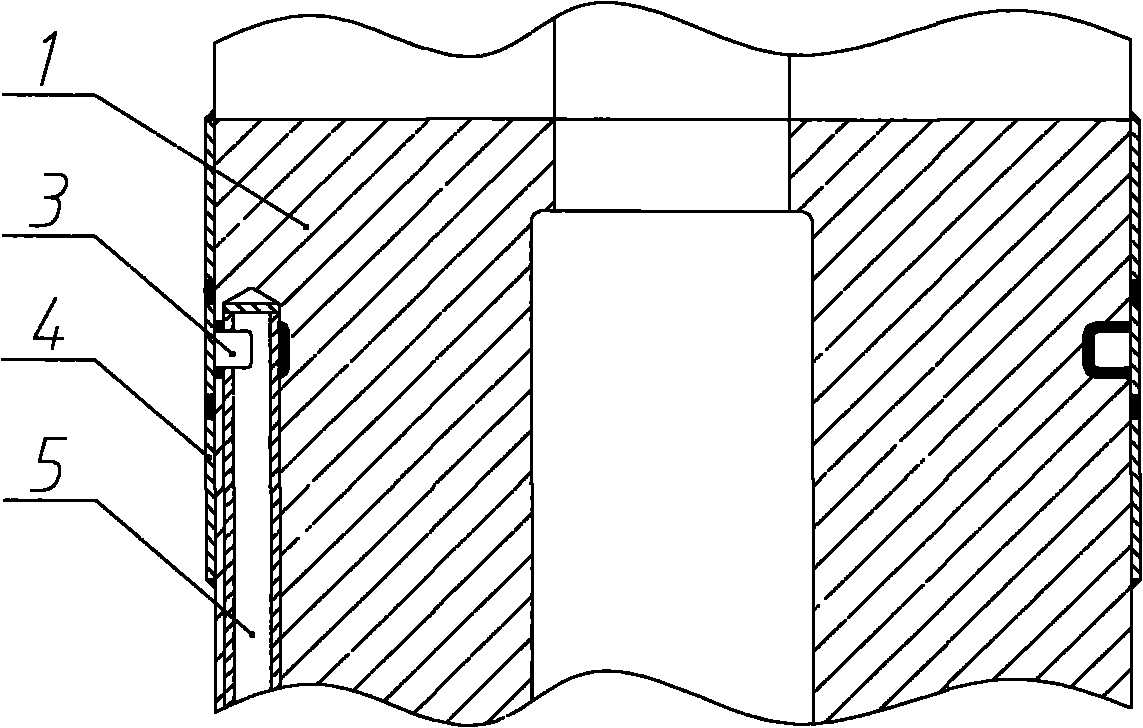

[0038] Example 2 as Figure 5-6 As shown, the short-circuit ring cooling structure of the vibrating table includes a short-circuit ring 4 arranged on the inner wall of the magnetic cylinder 2, two deep holes are arranged in the inner wall of the magnetic cylinder along the axial direction, and an annular groove 3' is opened on the inner wall of the magnetic cylinder. A cooling water pipe 5 with a closed upper end is respectively arranged in the deep holes, and the two cooling water pipes communicate with the annular groove 3' through an opening provided on the upper pipe wall, and the annular groove wall is fully copper stacked with the corresponding cooling water pipe wall. One of the cooling water pipes is also connected with the external cooling water supply equipment. The width of the short-circuit ring 4 is greater than the width of the annular groove, and the parts on the inner wall corresponding to the edges of both sides of the annular groove are sealed with the inner w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap