Low-temperature stickiness knock test equipment of asphalt and aggregate and test method thereof

A test equipment and adhesion technology, applied in the direction of flow characteristics, analysis materials, measuring devices, etc., can solve the problems of unfavorable low temperature adhesion control indicators, reduced test accuracy, eccentric impact of steel balls, etc., to achieve simple structure and operation. Convenience and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

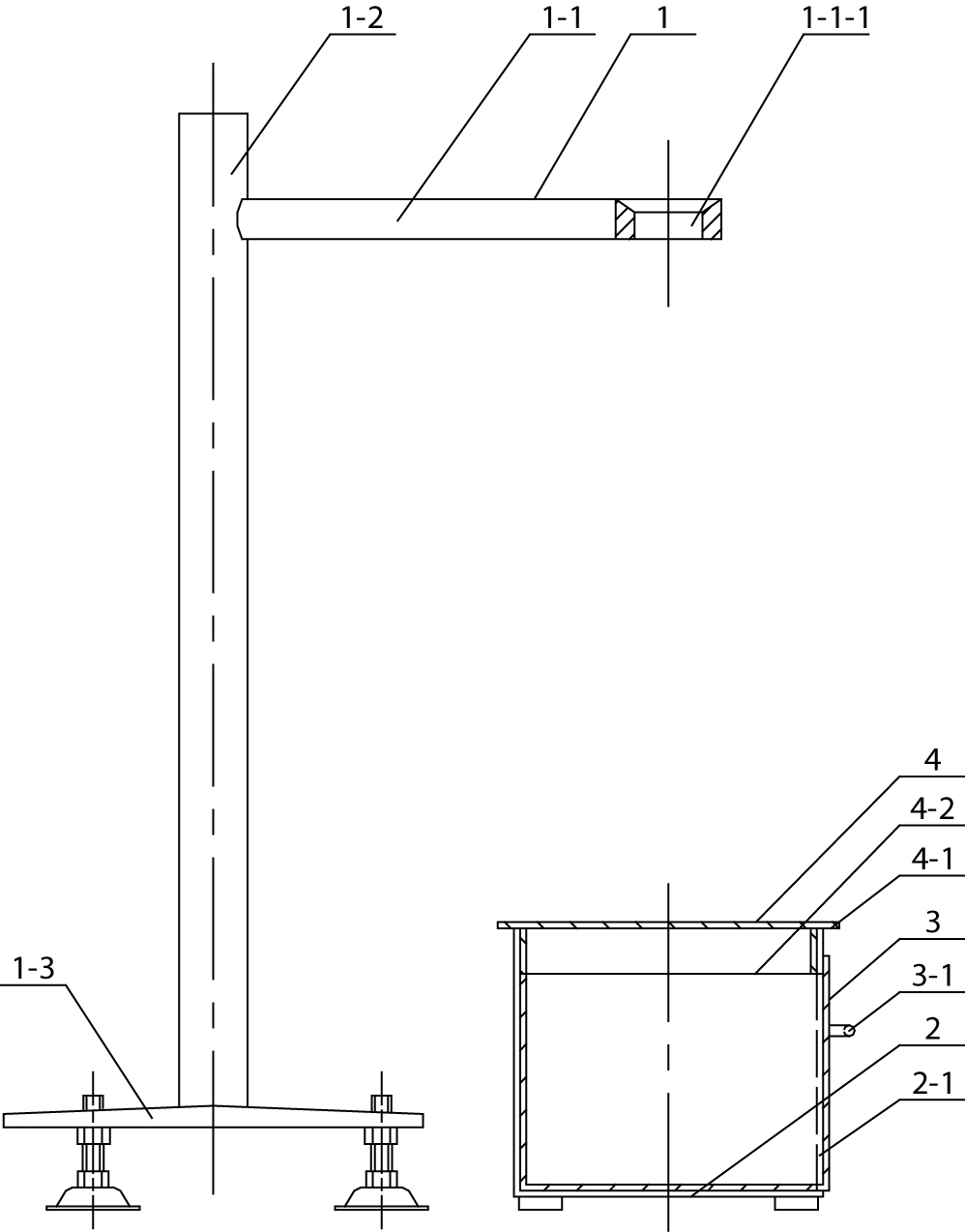

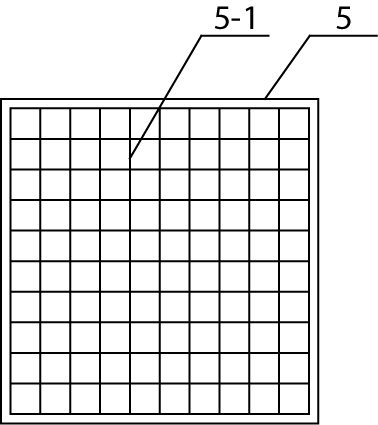

[0016] Specific implementation mode one: combine Figure 1 to Figure 6 Describe the low-temperature adhesion percussion test equipment for asphalt and aggregates of this embodiment, which includes a steel ball support frame 1, a specimen frame body 2, a crushed stone collection tank 3 and a specimen forming tank 4, and the crushed stones are collected The tank 3 is a tank body with an open upper end, a handle 3-1 is provided on one side of the gravel collection tank 3, the specimen frame body 2 is a tank body with an open upper end, and the middle and lower part of one side surface of the specimen frame body 2 is An opening 2-1 is provided, and the main body of the gravel collection tank 3 is arranged in the specimen frame body 2 through the opening 2-1, and the bottom surface of the specimen forming groove 4 is placed on the specimen frame body 2 upwards, and the steel ball The axes of the through hole 1-1-1 on the support frame 1, the test piece frame body 2, the gravel coll...

specific Embodiment approach 2

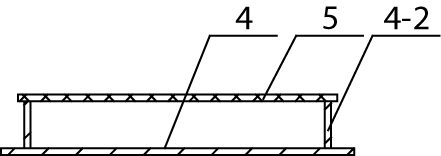

[0017] Specific implementation mode two: combination Figure 4 Describe the low-temperature adhesion knocking test equipment for asphalt and aggregates in this embodiment. The test piece forming groove 4 is a groove body with a closed frame 4-2 around it, and the bottom surface of the test piece forming groove 4 extends beyond the frame 4-2. 2 outside form a horizontal convex edge 4-1, when the test piece forming groove 4 is placed upside down on the test piece frame body 2, the closed frame 4-2 is located in the test piece frame body 2, and the horizontal convex edge 4-1 is located in the test piece frame body 2 the upper end of the side. Other components and connections of this embodiment are the same as those of Embodiment 1.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 and Figure 4 The low-temperature adhesive percussion test equipment for asphalt and aggregates in this embodiment is described. The height of the closed frame 4-2 of the test piece forming groove 4 is 8mm. The other components and connections of this embodiment are the same as those of Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com