Automatic control system for sintered mixture moisture

An automatic control system and sintering mixture technology, which is applied in the direction of control/regulation system, non-electric variable control, humidity control, etc., can solve the problem that the water content of the sintering mixture is difficult to control stably, and it is difficult to guarantee the improvement accuracy and reduce the The effect of labor intensity and small fluctuation

Inactive Publication Date: 2010-10-20

CHONGQING UNIV

View PDF7 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above factors make it difficult to control the water content of the sinter mixture stably at an appropriate value

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

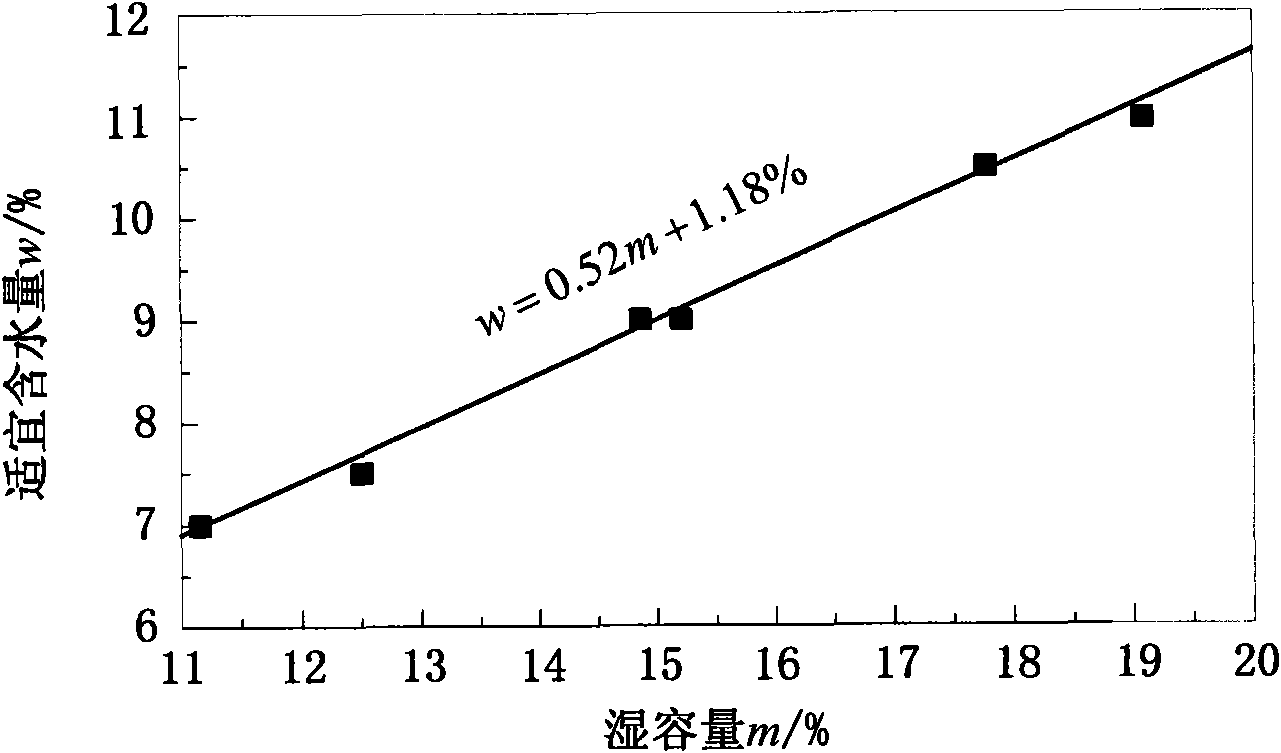

[0043] Taking certain iron ore powder as an example, the granulation effect is controlled by the sintering mixture moisture automatic control system of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

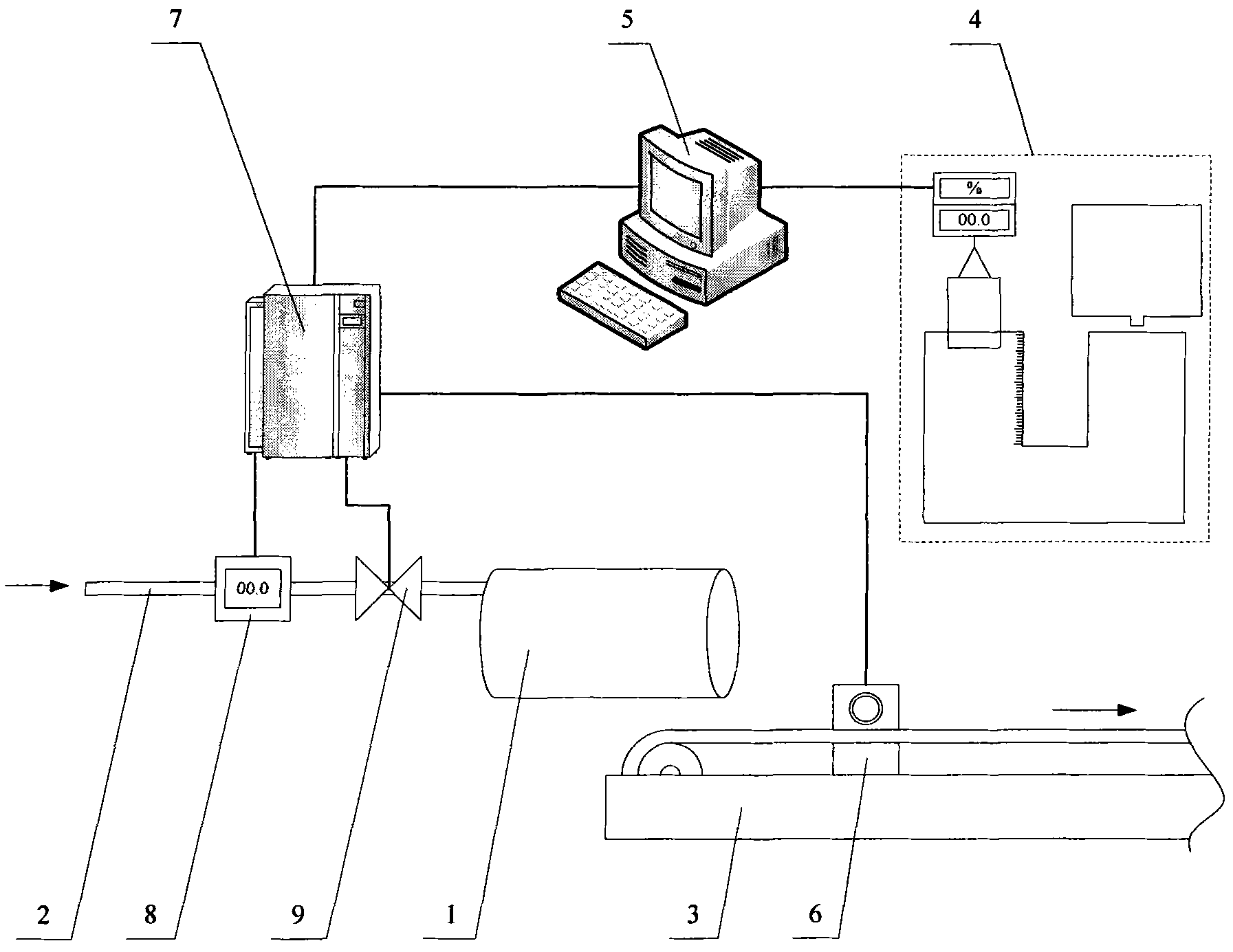

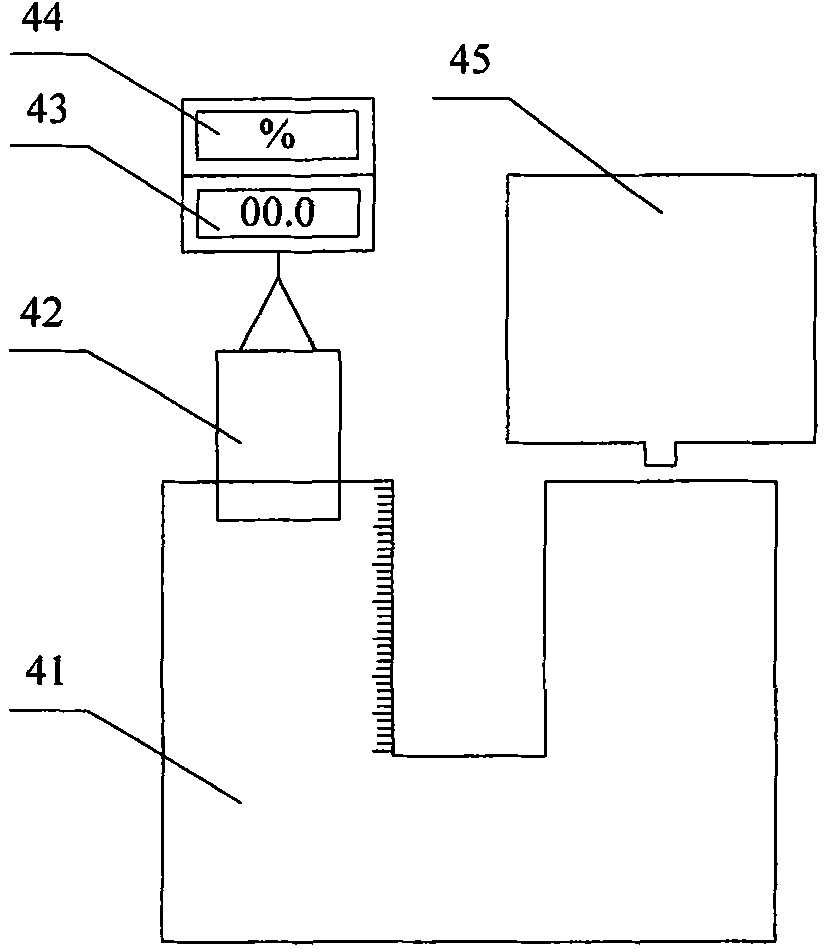

The invention provides an automatic control system for sintered mixture moisture. By measuring the wet capacity of the sintered mixture, predicting proper water content of the sintered mixture according to the wet capacity and adjusting and controlling the water adding amount of a granulating process according to the proper water content prediction value and the on-line detected practical water content to finally stabilize the water content of the sintered mixture at a proper value, the system realizes automatic control of the optimal water distribution quantity of the granulating process and on-line real-time control, effectively overcomes the defect that the water distribution quantity precision manually controlled at present is difficultly ensured, and greatly reduces the labor intensity of operators; and meanwhile, the system has the advantages of short control and stabilizing time and low fluctuation, and effectively overcomes the defect of water distribution quantity error caused by objective factors such as climatic change and the like.

Description

technical field [0001] The invention belongs to the field of iron and steel metallurgy, and in particular relates to an automatic control system for moisture content of sintering mixture. Background technique [0002] In the field of iron and steel metallurgy, iron ore powder, coke, flux, etc. are mixed with water, and the pellets of the mixture with a certain particle size distribution are obtained through the granulation of the cylinder mixer. Sinter for ironmaking. In the granulation process, the amount of water distribution has an important influence on the pelletizing behavior of the mixture and the particle size distribution of the final mixture pellets: with the increase of moisture, the air permeability of the mixture increases and the productivity increases; If the water content is too large, an over-wet zone will be formed on the sintering section, which will increase the resistance of the material layer and increase energy consumption; if the water content is too...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05D22/02

Inventor 吕学伟白晨光潘成邱贵宝张生富扈玫珑

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com