Reverse flux-weakening control type intelligent permanent magnet contactor with no position sensor

A weak field control and sensor technology, used in relays, circuit devices, electrical components, etc., can solve the problems of large displacement or speed sensors, increased failure probability, and increased costs, to improve electrical and mechanical life, permanent magnet suction force. Reduce, reduce the effect of a bounce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

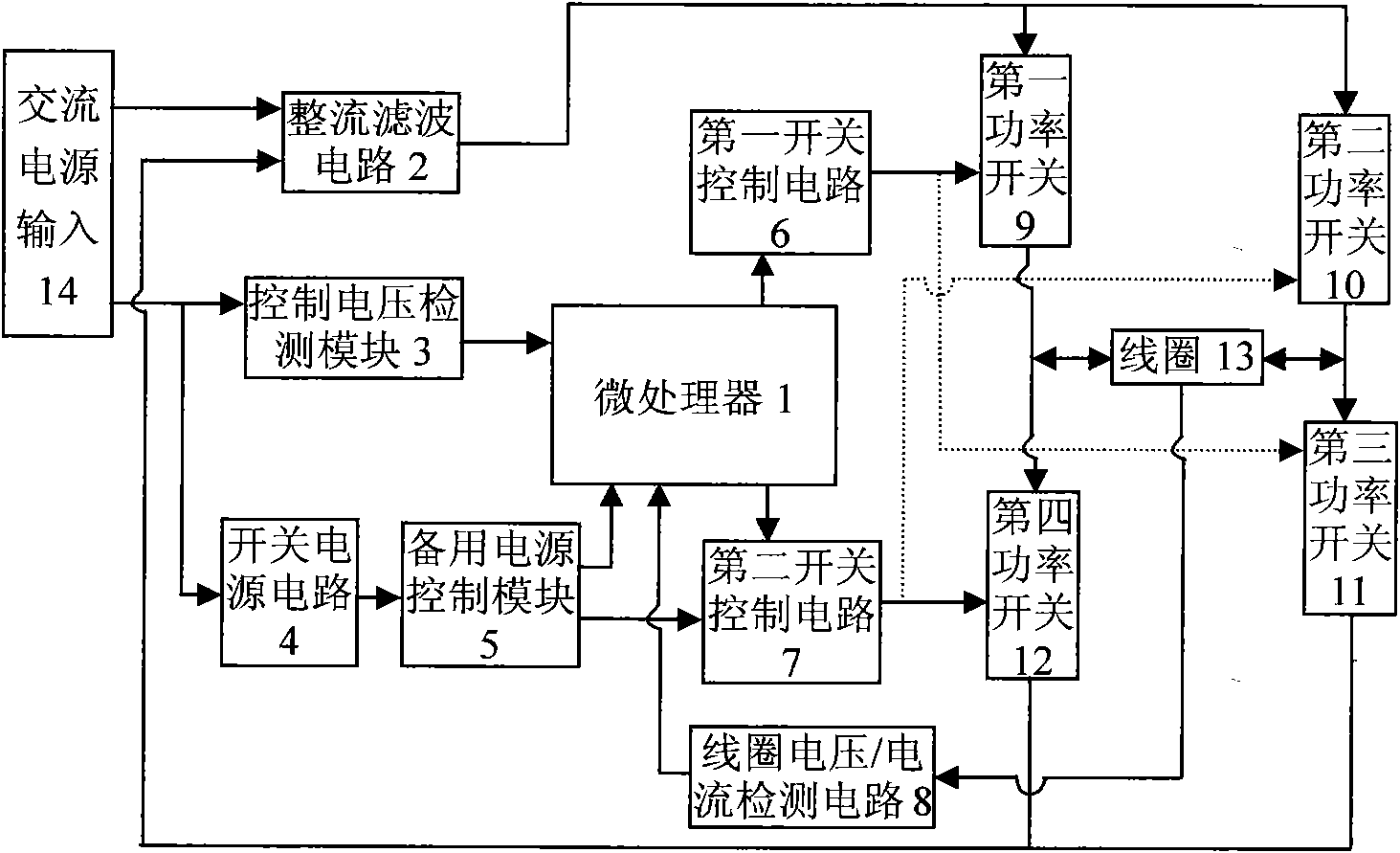

[0025] like figure 1 As shown, the intelligent permanent magnet contactor without position sensor reverse field weakening control of the present invention mainly includes a microprocessor 1, a rectification filter circuit 2, a control voltage detection module 3, a switch control circuit, a power switch, and a coil voltage / current detection Circuit 8, switching power supply circuit 4, backup power supply control module 5, etc. Wherein the first switch control circuit 6 drives the first power switch Q1 and the third power switch Q3 to conduct to realize the forward magnetization of the coil; the second switch control circuit 7 drives the second power switch Q2 and the fourth power switch Q4 to conduct to realize Reverse field weakening of the coil. The first path of the AC power input 14 passes through the rectifying and filtering circuit 2 to provide the required smooth DC voltage for the coil. The second path of the AC power input 14 is connected to the input terminal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com