Preparation method of nanometer silicon quantum dots and application thereof in film solar batteries

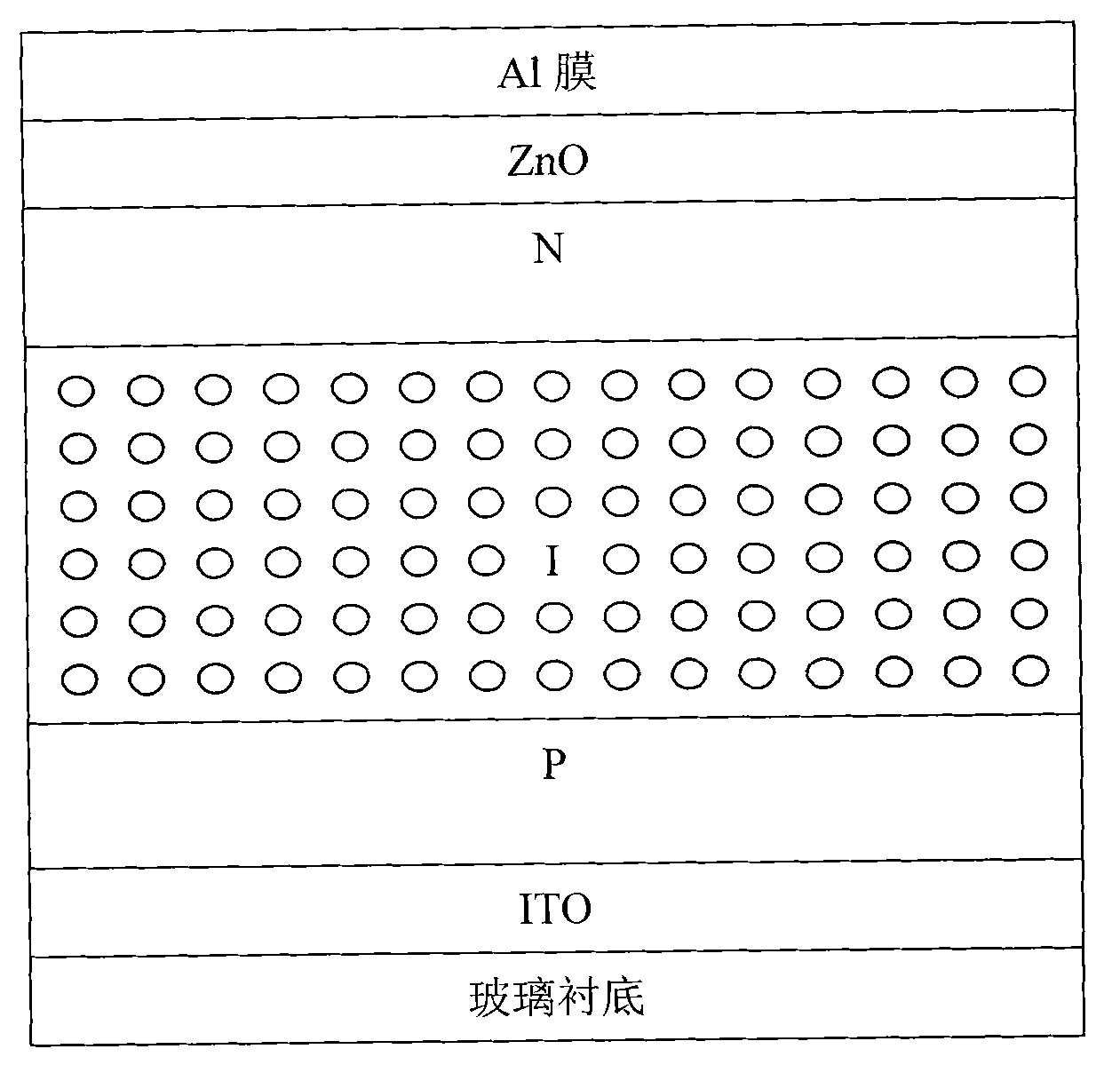

A technology of nano-silicon quantum dots and thin-film solar cells, which is applied in the manufacture of circuits, electrical components, and final products, and can solve the problems that the efficiency of nano-silicon or microcrystalline silicon thin-film solar cells has not been greatly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

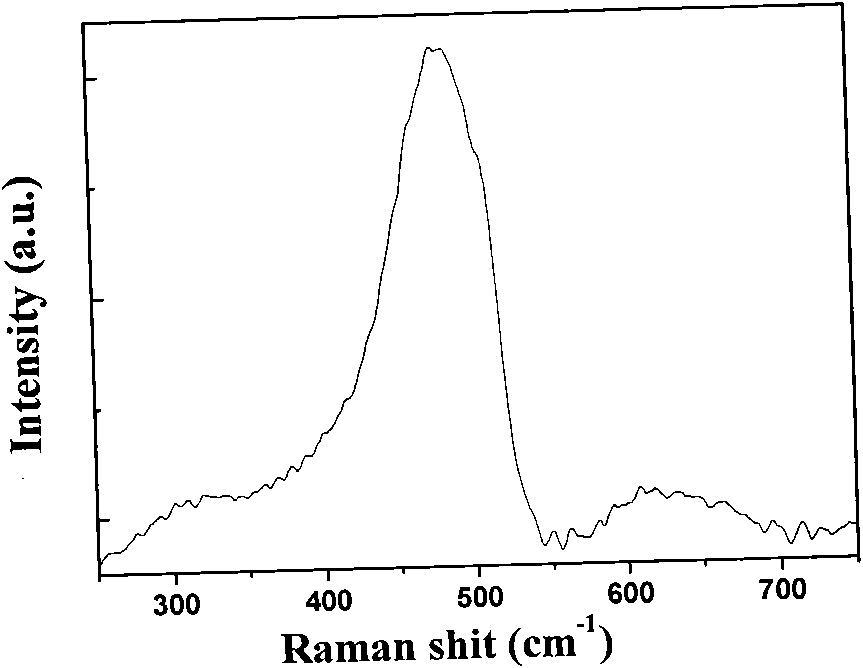

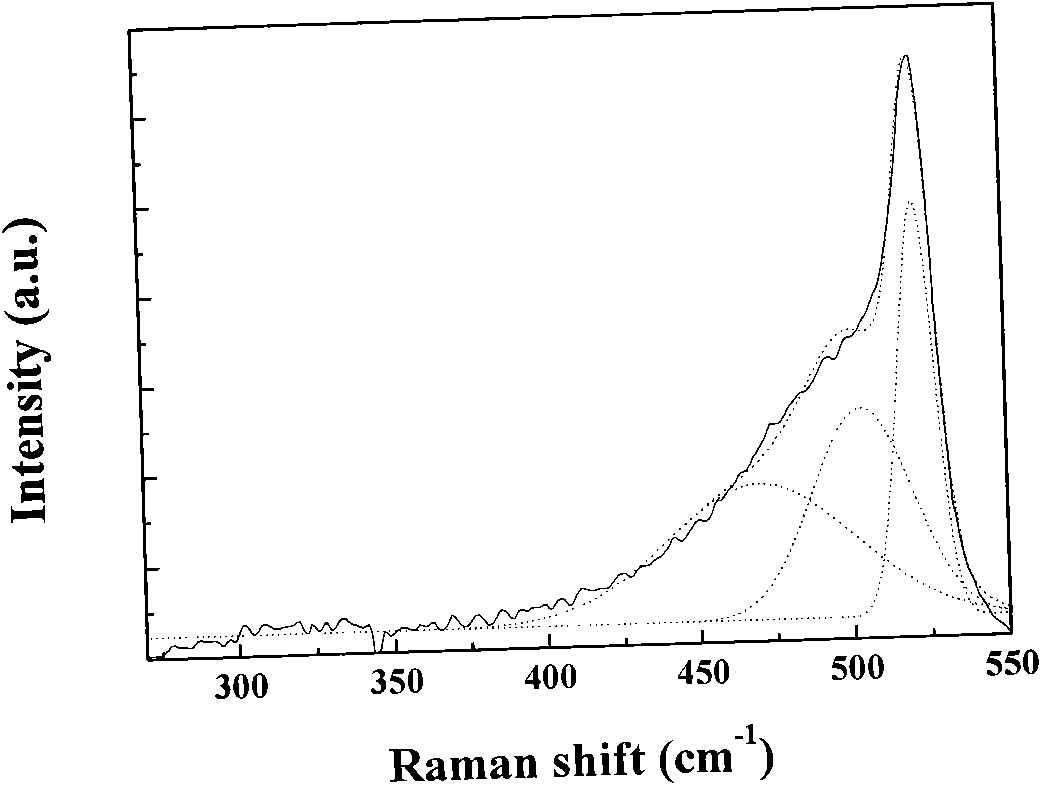

[0024] Preparation of Nano-Silicon Quantum Dots

[0025] 1. Growth of amorphous silicon on glass by PECVD method

[0026] Background vacuum 1.0×10 -4 Pa, the RF frequency is 13.56MHz, the RF power is 120W, and the deposition temperature is 180°C. The dilution ratio of the silane used is 5%, the silane flow rate is 30 sccm, the hydrogen gas flow rate is 30 sccm, and the growth thickness of amorphous silicon is about 500 nm.

[0027] 2. Use double beams to scan layer by layer to crystallize the amorphous silicon film.

[0028] The specific parameters of the femtosecond laser are: the central wavelength of the output of the titanium sapphire regenerative amplifier laser is 800nm, and the 400nm linearly polarized light whose polarization direction is perpendicular to the fundamental frequency of 800nm light can be obtained through frequency doubling of the KDP crystal. The polarization state of the second laser is converted to circular polarization, and the laser energy incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com