Production method of arc-shaped solar panel

A technology of solar panels and production methods, applied in the manufacture of circuits, electrical components, final products, etc., can solve problems such as hindering the development of photovoltaic solar technology, inability to use flat-panel solar cells, and restricting the use range of solar panels to achieve production quality Easy to control, low added value of single cost, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

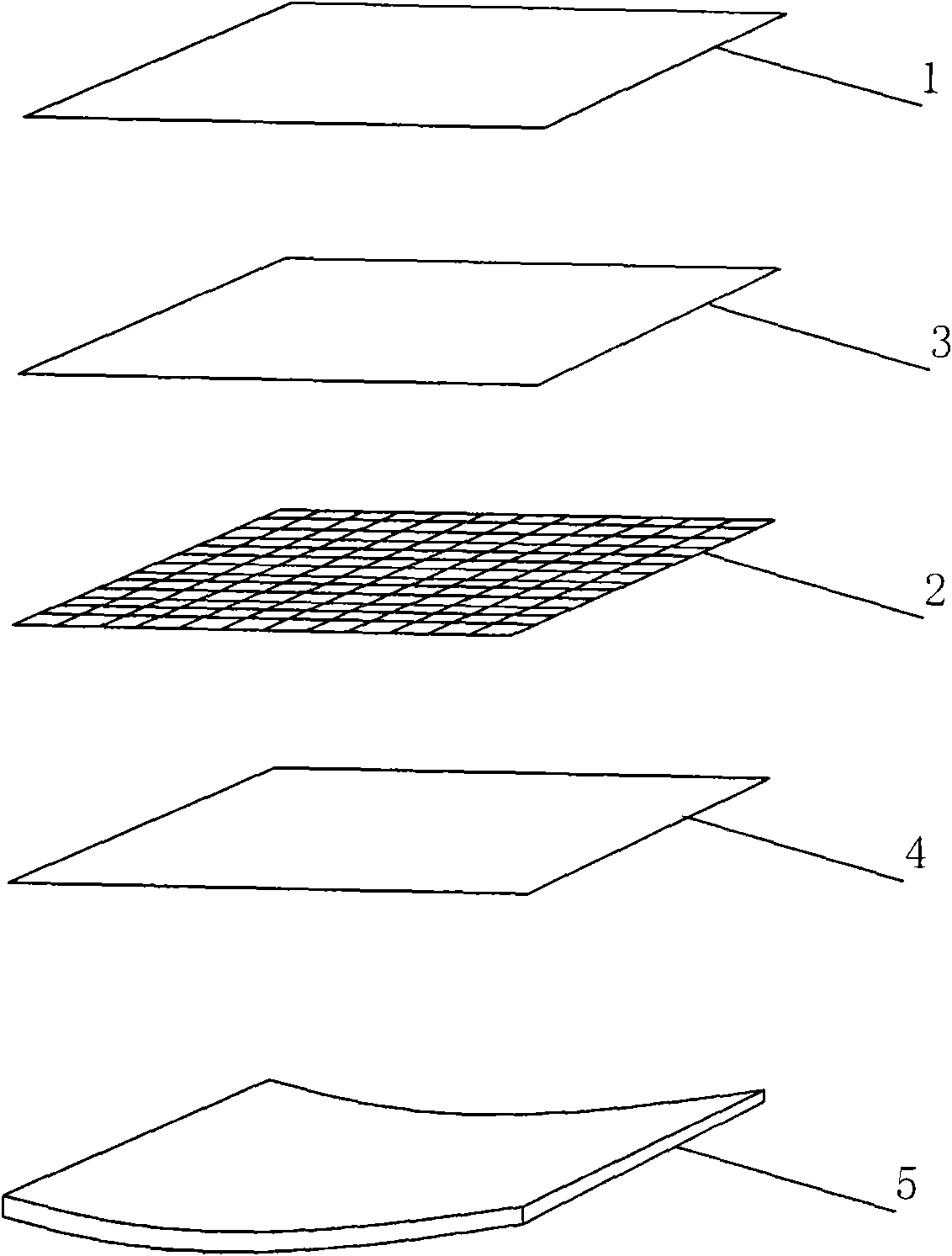

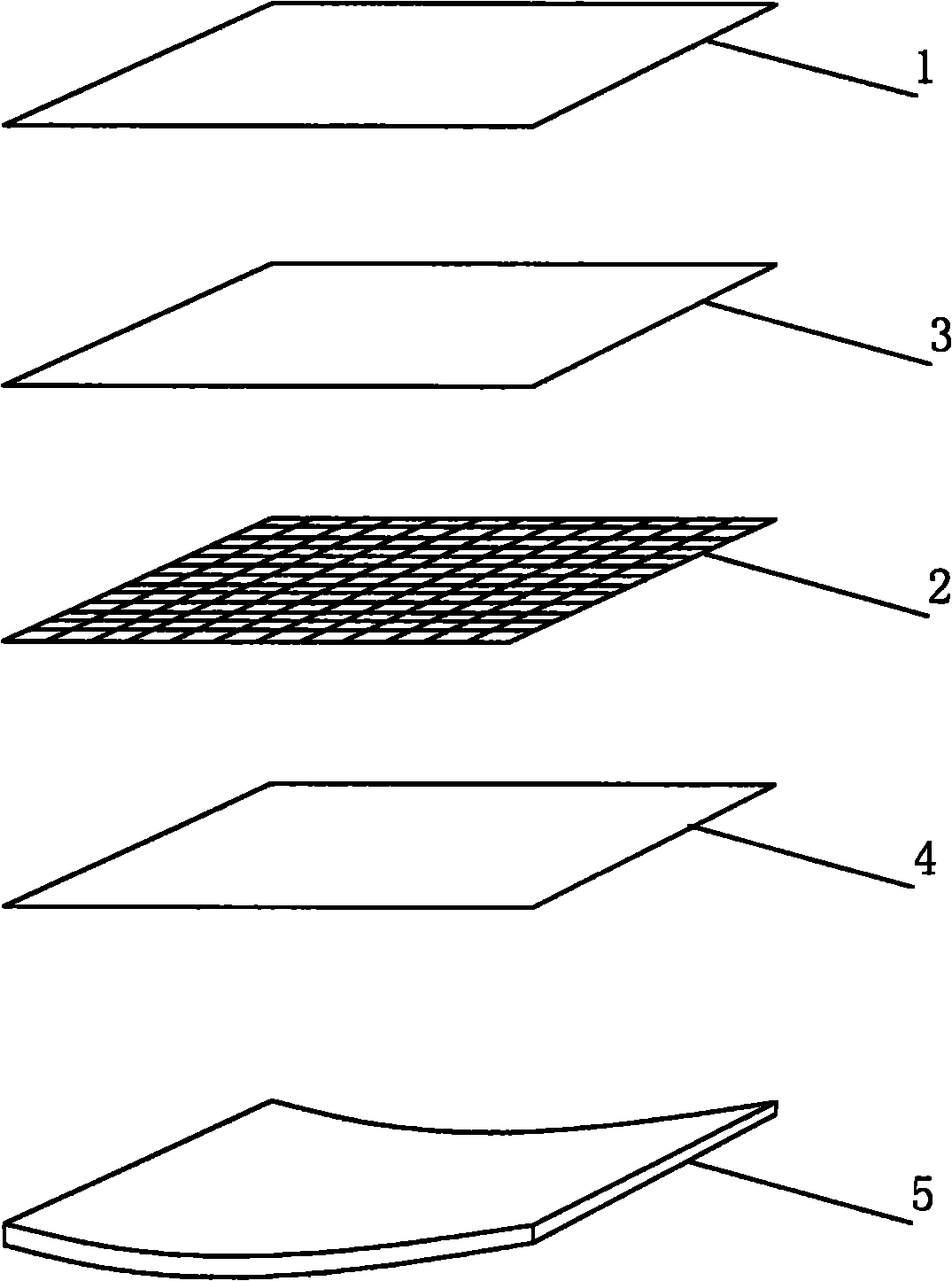

[0016] Such as figure 1 Shown, the production method of curved solar panel, the method steps are as follows,

[0017] a. Weld single-crystal silicon or polycrystalline silicon cells in series and form cell layer 2;

[0018] b. The arc-shaped tempered glass layer 5, the adhesive material layers 3 and 4, the battery sheet layer 2, and the back sheet material layer 1 are sequentially arranged from top to bottom as the back sheet material 1, the adhesive material layer 3, and the battery sheet layer 2 , the bonding material layer 4, and the arc-shaped glass layer 5 are stacked in sequence and the electrodes are drawn out;

[0019] c. Carry out arc-shaped lamination on the stack in step b in the lamination equipment through the special mold for arc-shaped lamination. 0.6~1.0Mpa, lamination temperature is 110℃~120℃, after lamination for 18min~20min, semi-finished products of curved solar panels are obtained;

[0020] d. After the arc-shaped lamination in step c is completed, fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com