Curable composition for dental applications

一种固化性组合物、化合物的技术,应用在牙科、牙科制剂、牙科假体等方向,能够解决复合树脂、修复体脱落的危险性高、不能得到满意粘接性、粘接强度下降等问题,达到牢固粘接、粘接耐久性优异、高粘接强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0480] Hereinafter, in order to demonstrate this invention concretely, although an Example and a comparative example are given and demonstrated, this invention is not limited to these examples at all. In addition, the kinds of various components used in the examples and comparative examples, and the test and evaluation methods of various physical properties are as follows.

[0481]

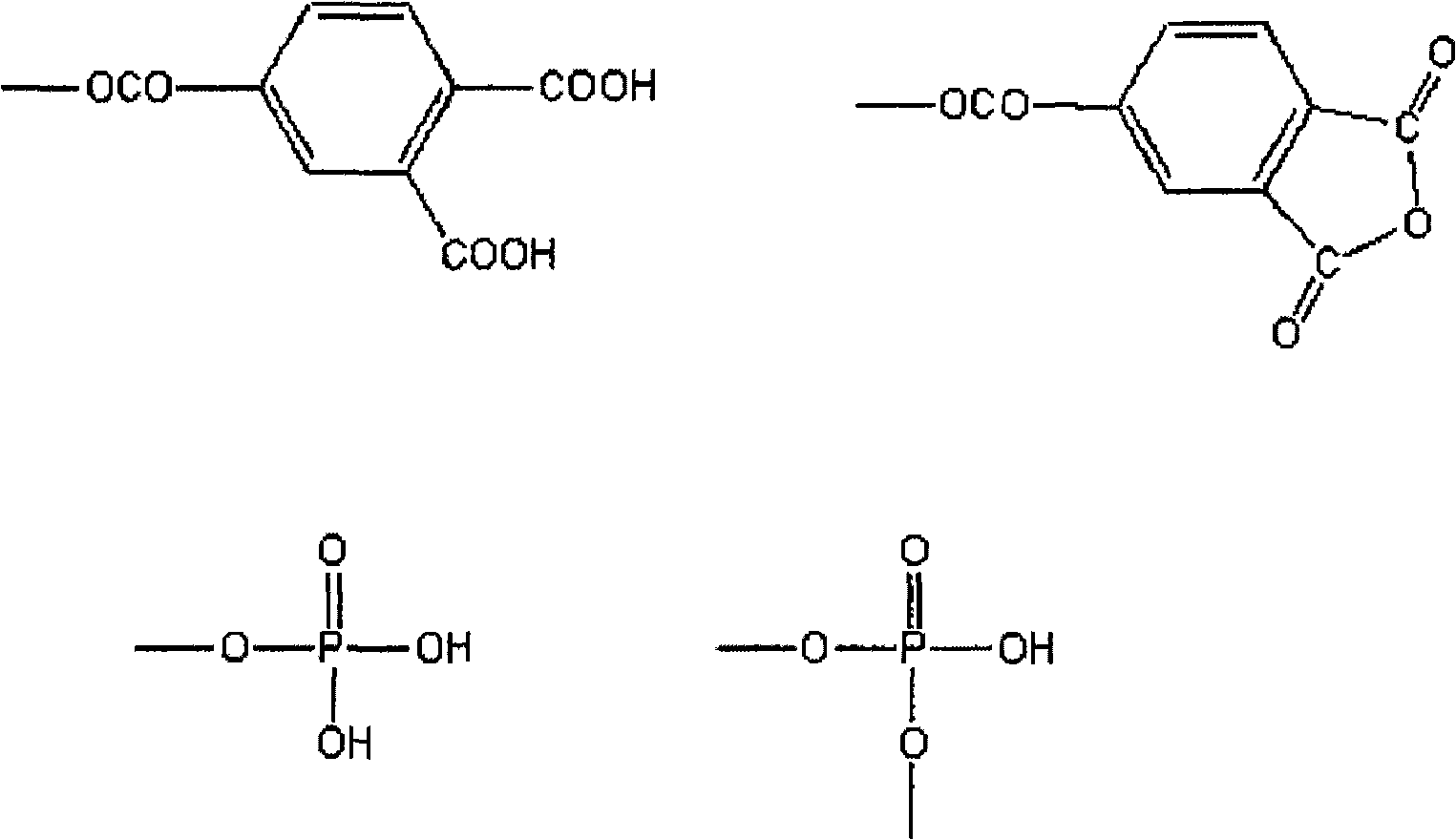

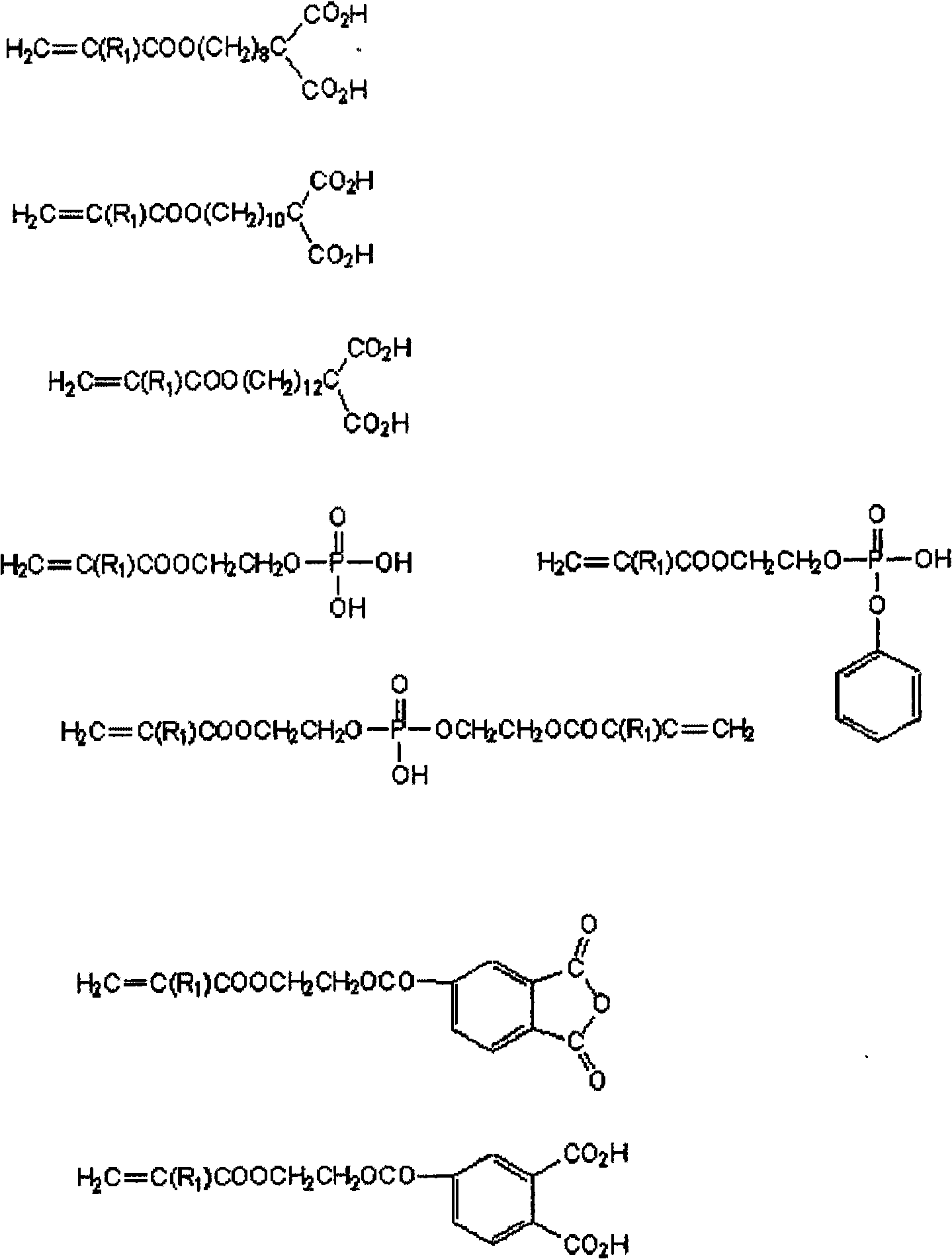

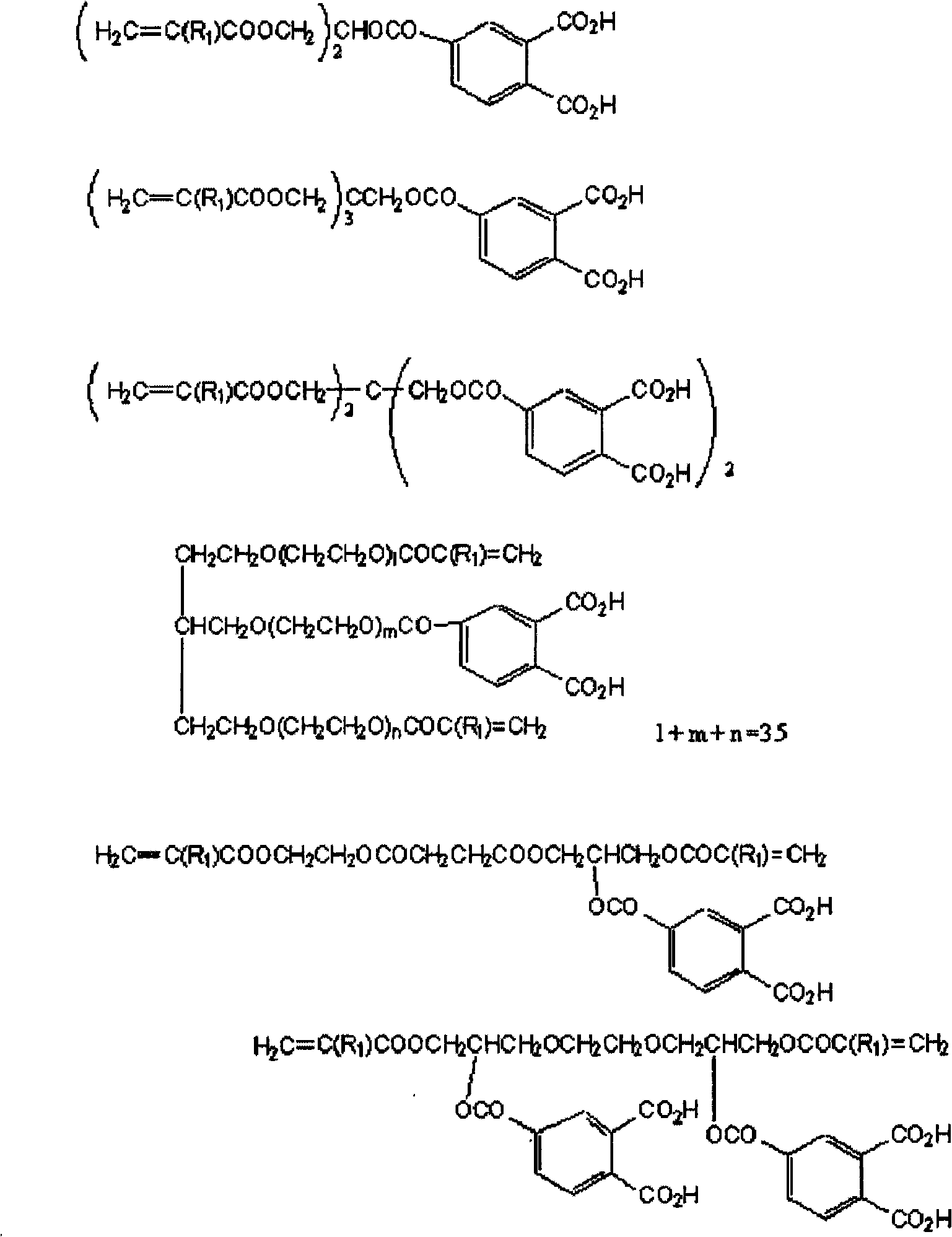

[0482] [(a-1) Acidic group-containing polymerizable monomer (acidic monomer)]

[0483] PM:

[0484] Mixture of 2-methacryloyloxyethyl dihydrogen phosphate and bis(2-methacryloyloxyethyl) hydrogen phosphate

[0485] MDPs:

[0486] 10-Methacryloxydecyl dihydrogen phosphate

[0487] MAC-10:

[0488] 11-Methacryloyloxy-1,1-undecanedicarboxylic acid

[0489] In addition, the above-mentioned acidic monomer (a-1) also functions as a reactive species in the aryl borate-based chemical polymerization initiator component.

[0490] [(a-2) Polymerizable monomer not containing an acidic group (non-acidi...

manufacture example 1

[0579] Fluoroaluminosilicate glass powder (Tokuso Aionoma manufactured by Tokuyama Denko Co., Ltd.) was pulverized to an average particle size of 0.5 μm with a wet continuous ball mill (Niyumimil manufactured by Mitsui Mining Co., Ltd.). 1 g to 20 g of 5.0 N hydrochloric acid was used to treat the surface of the filler for 40 minutes to obtain a polyvalent metal filler (F-1).

[0580] 0.1 g of the obtained polyvalent metal filler (F-1) was immersed and kept in 10 ml of a 10% by weight aqueous solution of maleic acid at a temperature of 23° C. for 24 hours, and analyzed by ICP (inductively coupled plasma) emission spectrometry. The amount of dissolved polyvalent metal ions.

[0581] As a result, the amount of dissolved ions in 24 hours of the polyvalent metal filler (F-1) was 10meq / g-filler (Al 3+ =6.7, La 3+ =2.8, Ca 2+ = 0.5).

manufacture example 2

[0583] A polyvalent metal filler (F-2) was obtained in exactly the same manner as in Production Example 1 except that the treatment time with 5.0N hydrochloric acid was changed to 20 minutes.

[0584] As a result of the ICP emission spectrometry, the amount of ions dissolved in 24 hours of the polyvalent metal filler (F-2) was 25meq / g-filler (Al 3+ =16.7, La 3+ =6.9, Ca 2+ = 1.4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com