Improved preparation method of rebamipide intermediate

A technology for rebamipide and intermediates, which is applied in the field of preparation of improved rebamipide intermediates, can solve problems such as low product purity, low reaction yield, and increased cost, and achieve high product purity and increase product yield. The effect of high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

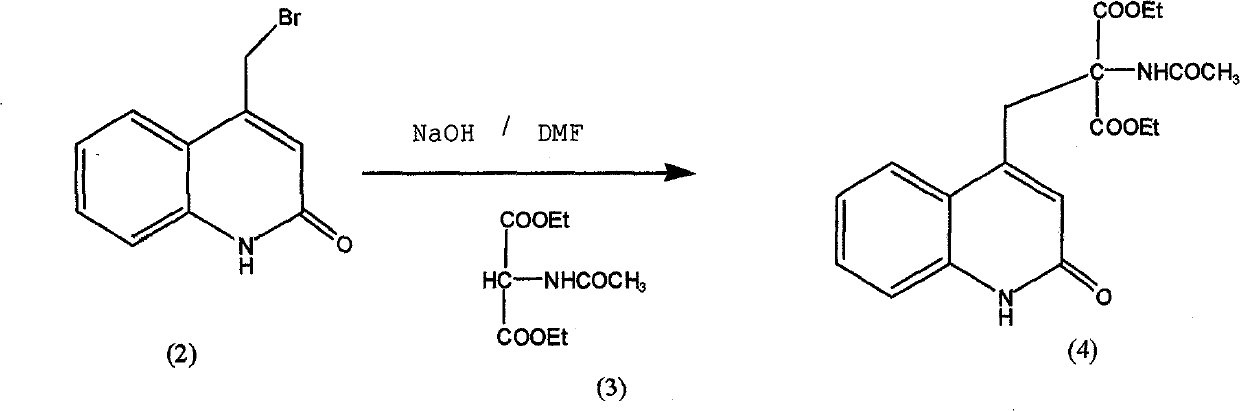

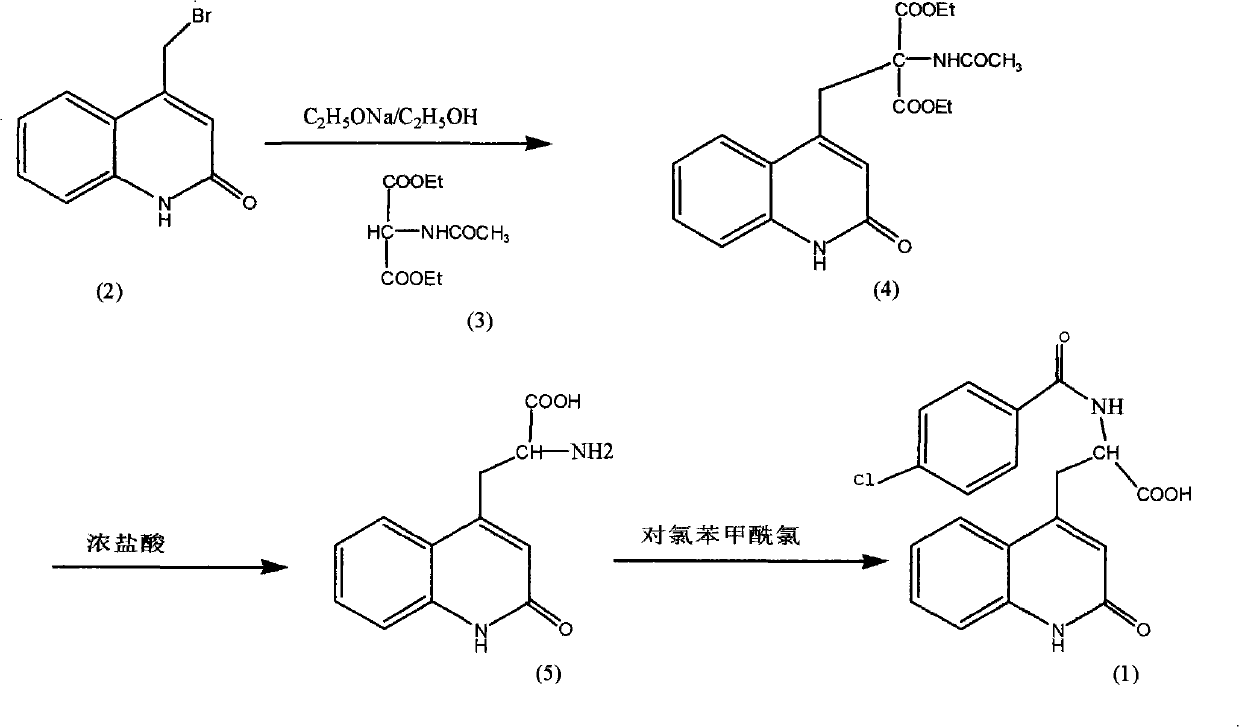

Method used

Image

Examples

Embodiment 1

[0015] Under a water bath, add 75mL of DMF to a 250mL three-neck flask, cool to 20°C, slowly add 2.8g of NaOH under stirring, continue stirring for 30 minutes after adding, cool down to 10-15°C, add 13.5g of intermediate (3) at one time, add Stir for another 30 min, then add 12.4 g of intermediate (2), and stir for 2 hours at 15°C. The temperature was raised to 30° C., and the reaction was continued for 3 hours.

[0016] Cool in an ice-water bath to 10° C., stir for 1 hour, a large amount of precipitation occurs in the middle, filter, and wash the filter cake with water until the pH is neutral to obtain 17.5 g of white powder with a yield of 90% and a purity of 98.83% (HPLC).

Embodiment 2

[0018] Under a water bath, add DMF1500mL to a 3000mL three-necked flask, cool to 20°C, slowly add 56.0g of NaOH under stirring, continue stirring for 45 minutes after adding, cool down to 10-15°C, add 270g of intermediate (3) at one time, Stir for another 30 min, then add 248 g of intermediate (2), and stir for 2 hours at 15°C. The temperature was raised to 30° C., and the reaction was continued for 3 hours.

[0019] Cooled to 10°C in an ice-water bath, stirred for 1 hour, a large amount of precipitation occurred in the middle, filtered, and the filter cake was washed with water until the pH was neutral to obtain 345.7 g of white powder with a yield of 88.7% and a purity of 98.64% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com