Method for preparing polyaniline nanometer wires by using ultrasonic radiation

A technology of ultrasonic radiation and polyaniline, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of cumbersome reaction process, high cost, unfavorable mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

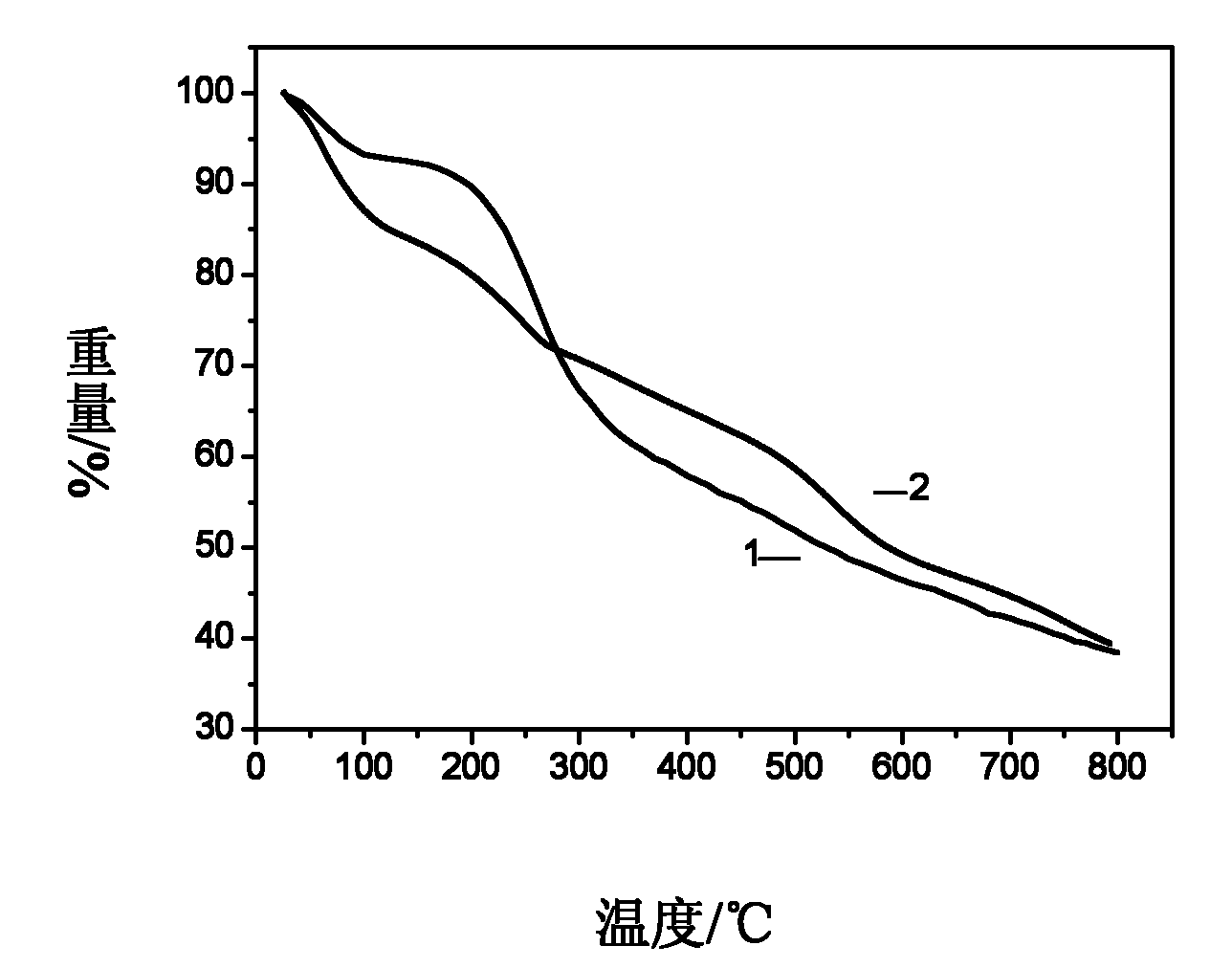

Embodiment 1

[0018] Add 200ml of 1mol / l hydrochloric acid (HCl) into a 250ml three-neck flask, stir for 30min, then take 1ml of aniline (ANI), and dropwise add it to the reaction solution at a rate of 0.02ml / min. After continuing to stir for 1 hour, 50 ml of a solution containing 2.5 g of ammonium persulfate was taken and added dropwise to the reaction solution at a rate of 1 ml / min. The reaction was carried out at 20° C. for 8 hours under continuous stirring. During the whole process of the reaction, it is accompanied by ultrasonic irradiation (300W). After the reaction, the HCl-doped PANI nanorods were obtained after suction filtration, washing with dilute hydrochloric acid, absolute ethanol, and deionized water, and vacuum drying at 45°C.

Embodiment 2

[0020] Add 200ml of 1mol / l hydrochloric acid (HCl) into a 250ml three-neck flask, stir for 30min, then take 1ml of aniline (ANI), and dropwise add it into the reaction solution at a rate of 0.05ml / min. After continuing to stir for 1 hour, 50 ml of a solution containing 2.5 g of ammonium persulfate was added dropwise to the reaction solution at a rate of 3 ml / min. The reaction was carried out at 24°C for 6 hours under continuous stirring. During the whole process of the reaction, it is accompanied by ultrasonic irradiation (300W). After the reaction, the HCl-doped PANI nanorods were obtained after suction filtration, washing with dilute hydrochloric acid, absolute ethanol, and deionized water, and vacuum drying at 45°C.

Embodiment 3

[0022] Add 200ml of 1mol / l hydrochloric acid (HCl) into a 250ml three-neck flask, stir for 30min, then take 1ml of aniline (ANI), and dropwise add it into the reaction solution at a rate of 0.05ml / min. After continuing to stir for 1 hour, 50 ml of a solution containing 2.5 g of ammonium persulfate was added dropwise to the reaction solution at a rate of 3 ml / min. The reaction was carried out at 16° C. for 10 hours under continuous stirring. During the whole process of the reaction, it is accompanied by ultrasonic irradiation (300W). After the reaction, the HCl-doped PANI nanorods were obtained after suction filtration, washing with dilute hydrochloric acid, absolute ethanol, and deionized water, and vacuum drying at 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com