Preparation method of porous magnetic fluorescent nanosphere

A technology of fluorescent nanometers and nanospheres, which is applied in the field of materials, can solve problems such as difficulty in finding pores, and achieve the effect of increasing surface area and easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing porous magnetic fluorescent nanospheres, comprising the steps of:

[0029] Fe was first synthesized by thermal decomposition of iron oleate at a high temperature of 320°C 3 o 4 magnetic nanoparticles, the as-synthesized Fe 3 o 4 The particles were then dried at 40°C.

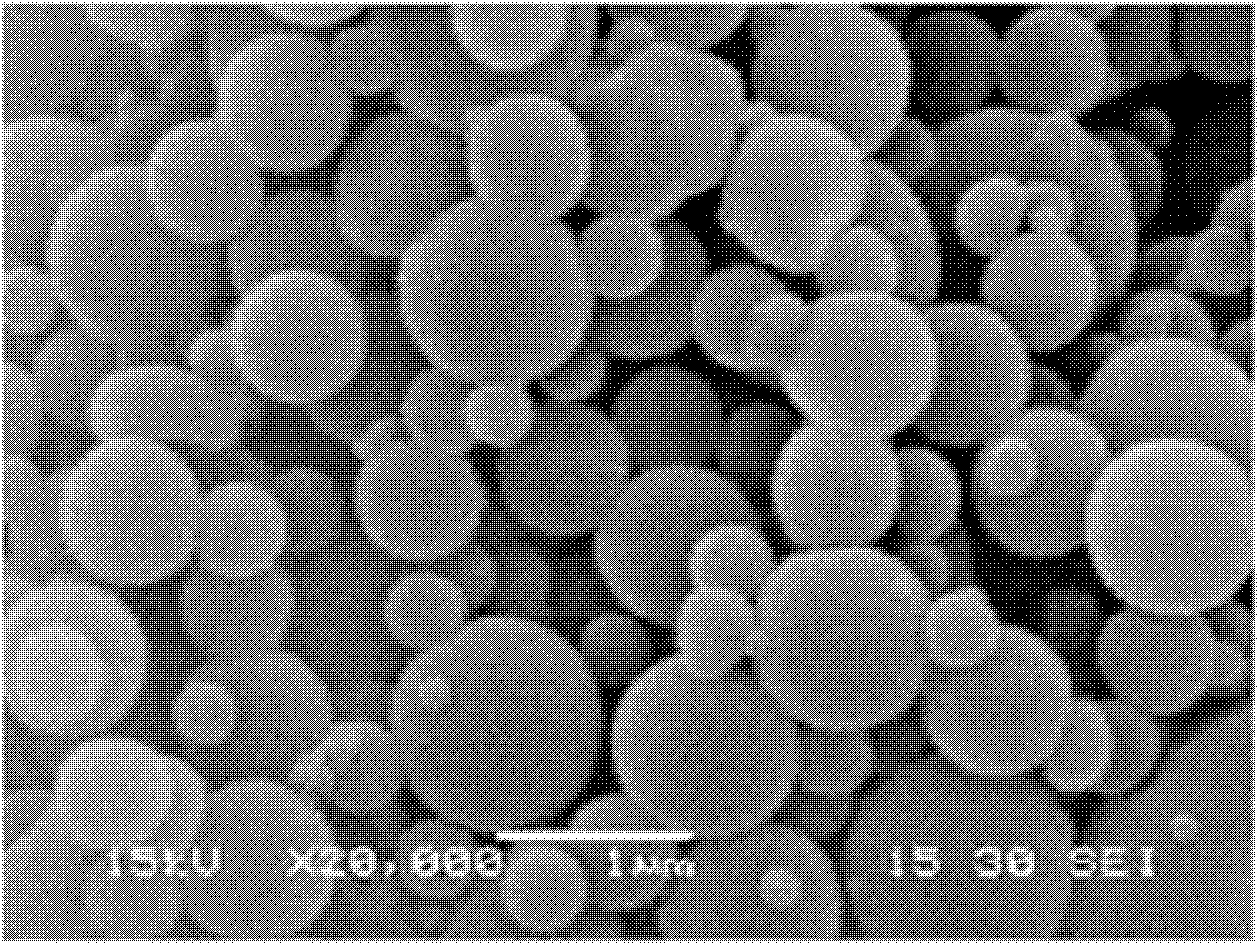

[0030] Accurately weigh the dry powder of ethyl cellulose (EC), dissolve it in ethanol to obtain an ethanol solution with an EC mass concentration of 5 mg / ml. The solution was divided into 2 equal parts, and the Fe concentration of 0.65 and 1.95 mg / ml was added to 3 o 4 nanoparticles, and then adopt the method of ultrasonic atomization drying, the EC-Fe 3 o 4 The ethanol solution was atomized into droplets, and then the droplets were dried at a drying temperature of 60°C to make porous magnetic ethylcellulose nanospheres.

[0031] Accurately weighed porous magnetic ethylcellulose nanospheres (EC-Fe 3 o 4 ) dry powder, dispersed in the quantum dot CdTe aqueous solution, the...

Embodiment 2

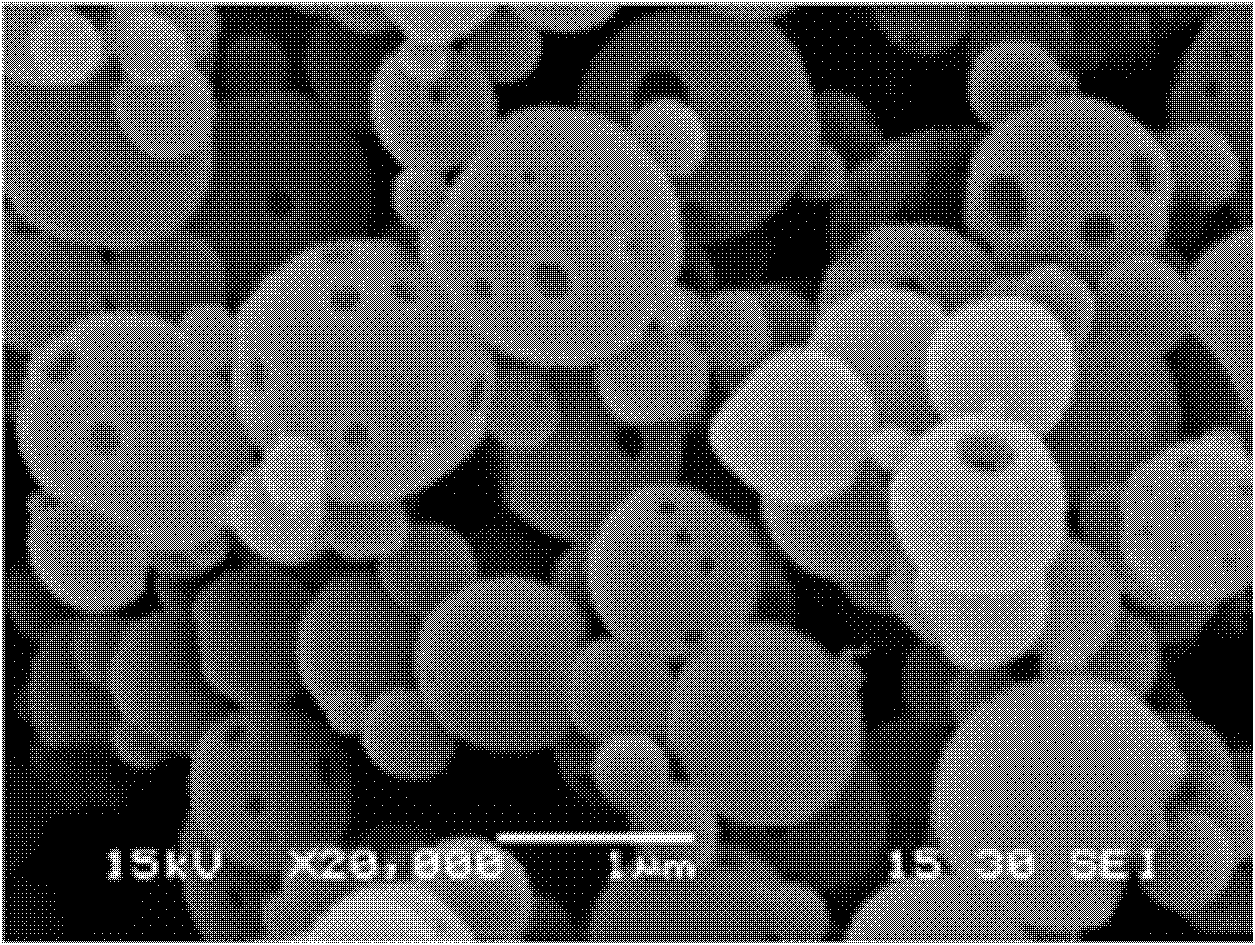

[0036] Ethanol solutions with ethyl cellulose concentrations of 1 mg / ml and 10 mg / ml were prepared respectively.

[0037] Add Fe to a 1 mg / ml ethylcellulose solution in ethanol 3 o 4 Nanoparticles that make Fe 3 o 4 The concentration of nanoparticles reaches 0.2mg / ml;

[0038] Add Fe to a 10 mg / ml ethylcellulose solution in ethanol 3 o 4 Nanoparticles that make Fe 3 o 4 The concentration of nanoparticles reaches 4mg / ml.

[0039] Each solution is divided into 2 parts (that is, 4 samples), and then atomized by ultrasonic waves, and the droplets are dried, and the drying temperature of each solution is 35°C and 95°C, respectively.

[0040] The results showed that the obtained porous magnetic ethylcellulose nanospheres (EC-Fe 3 o 4 ) nanospheres all contain holes, and the number and size of holes increase slightly when the temperature rises. But by changing Fe in Example 1 3 o 4 Compared with the amount of nanoparticles to control the morphology of pores, the effect o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com