Small-flow high-lift radial piston pump

A radial piston pump, high lift technology, applied in the field of positive displacement pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

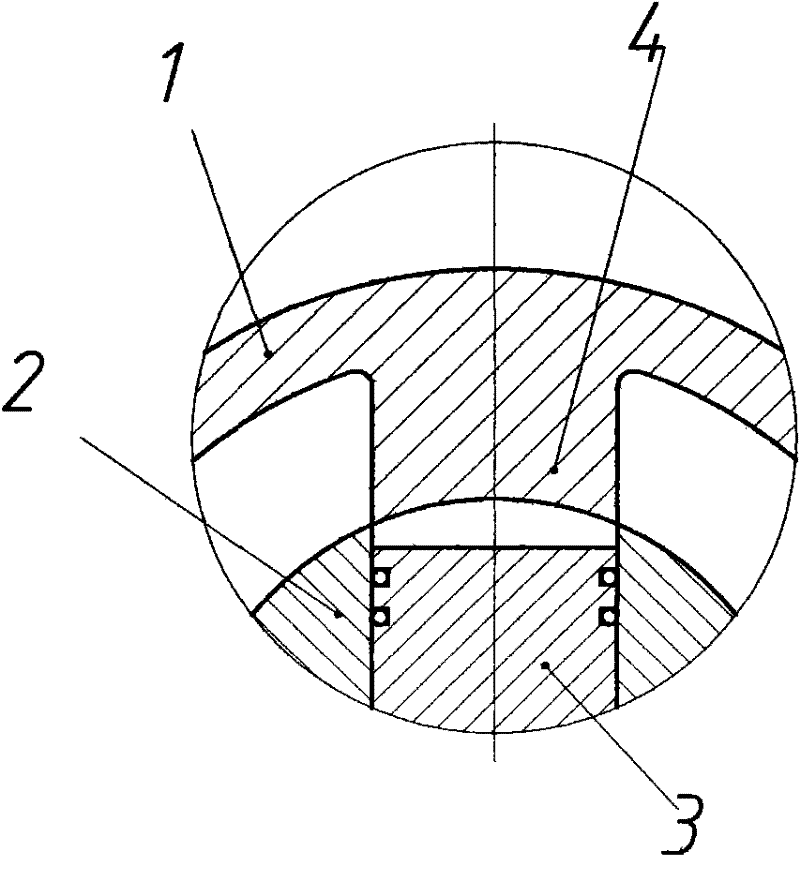

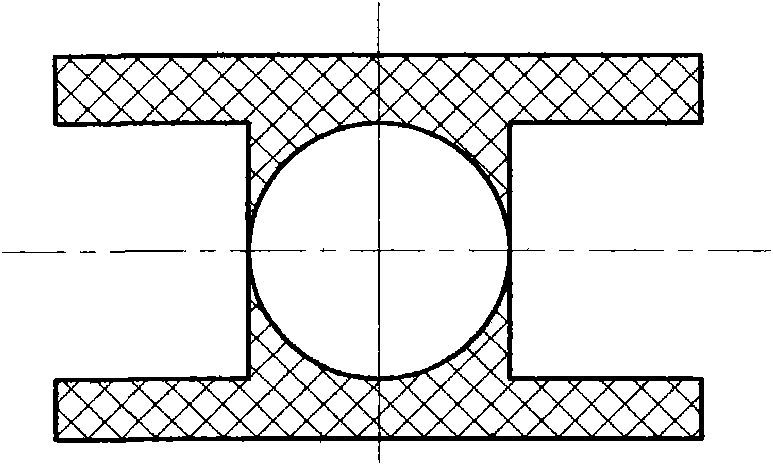

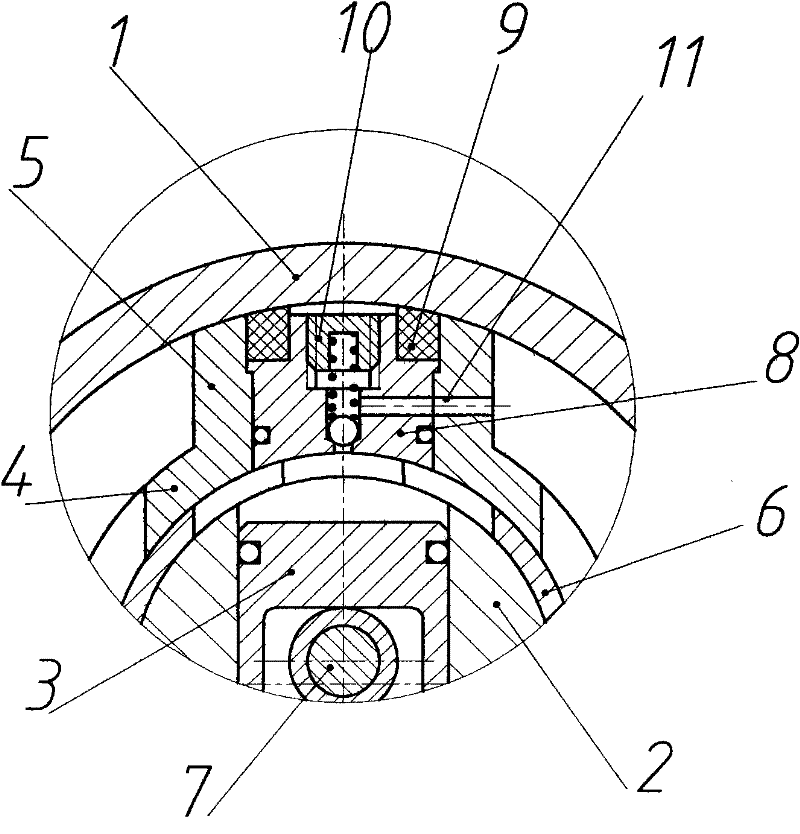

[0027] Figure 5 is an embodiment of the invention - a radial piston pump with double supported eccentric shafts 7 and double pistons 3, Image 6 for Figure 5 The B-B section view.

[0028] The figure shows pump body 1, rotor 2, piston 3, spacer tongue 4, spacer tongue sleeve 5, rotor sleeve 6, eccentric shaft 7, sealing compensation block 8, elastic pressure sleeve 9, discharge check valve 10, small channel 11 , pump cover 12, bearing 13, shaft seal device 14, motor 15, rolling ring 16, eccentric wheel 17.

[0029] In this example, a rotatable double-supported eccentric shaft 7 is adopted. One end of the eccentric shaft 7 is supported in the eccentric hole on the pump cover 12, and the other end is supported in the eccentric hole of the eccentric wheel 17 through the long groove of the waist of the piston 3. The eccentric wheel 17 is loosely installed in the inner cavity of the rotor 2 and is coaxial with it, and a rolling ring 16 is installed at the hinge joint between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com