Small rotor-type submersible pump

A submersible pump and rotor-type technology, applied in the field of positive displacement pumps, can solve the problems of easy wear, small width of the impeller outlet, and low cost, and achieve obvious social benefits, expand the scope of use, and reduce hydraulic loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

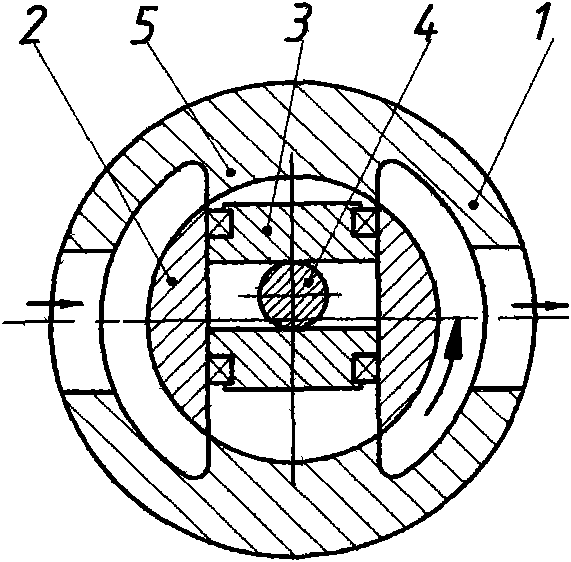

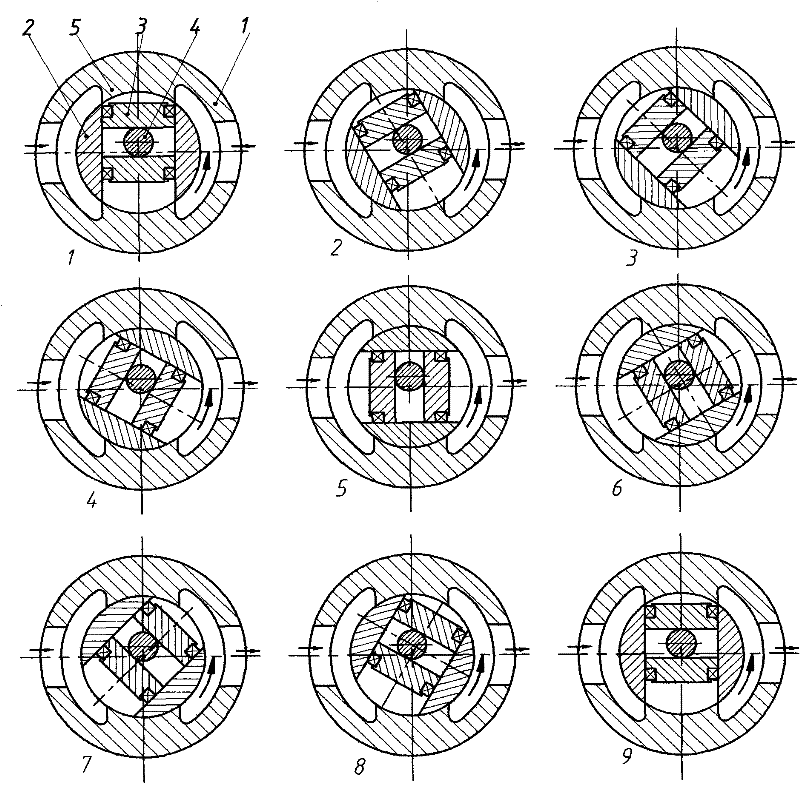

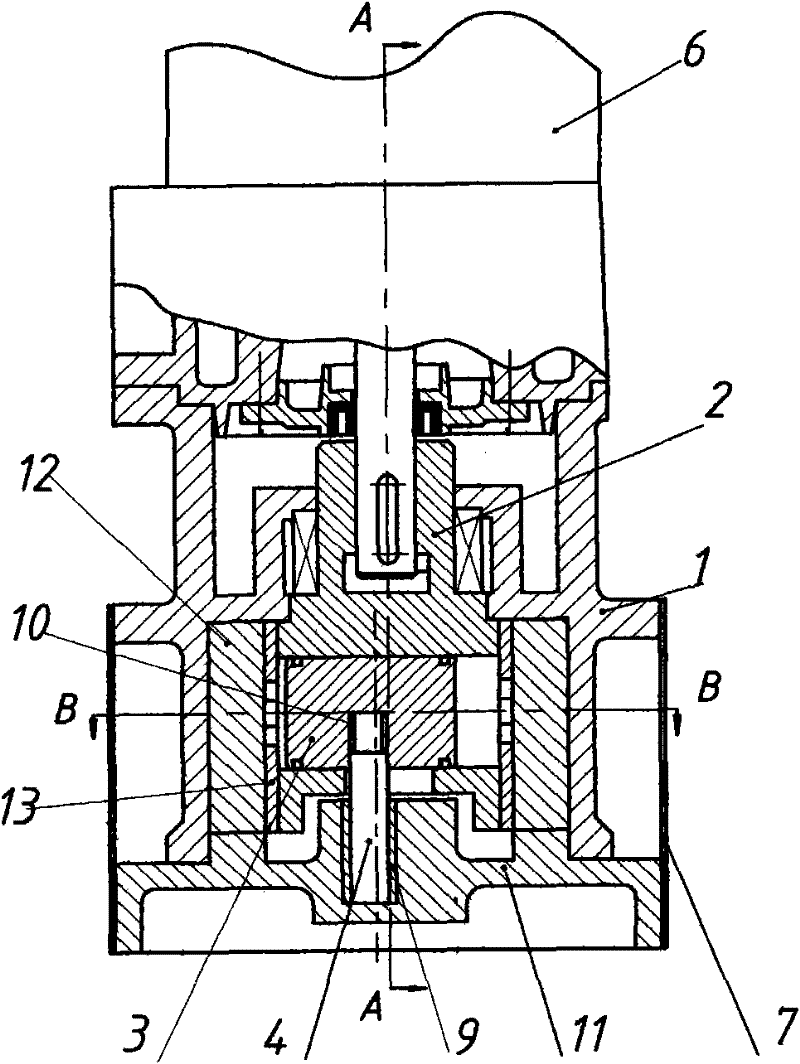

[0036] image 3 , Figure 4 , Figure 5Represents the first embodiment of the rotor submersible pump, as shown in the figure, 1 is the pump body, 2 is the rotor, 3 is the piston, 4 is the eccentric shaft, 5 is the tongue on the tongue sleeve 13, and 6 is the submersible motor , 7 is a filter screen, 8 is a shaft seal device, 9 is a bearing, 10 is a rolling ring, 11 is a pump seat, 12 is a tongue cover, and 13 is a rotor cover.

[0037] In this embodiment, a pair of partition tongues 5 on the partition tongue cover 13 divide the inner cavity of the pump body 1 into a suction chamber and a discharge chamber. The width of the partition tongue 5 is equal to the width of the radial channel on the rotor sleeve 13. When the submersible motor 6 When the rotor 2 is driven to rotate, the piston 3 also rotates. Since the piston 3 is restricted by the eccentric shaft 4, it makes a relative reciprocating motion along the radial through hole during the rotation process, resulting in a vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com