Photosensitive resin composition, flexible circuit board employing the same, and circuit board production method

一种感光性树脂、电路基板的技术,应用在电路基板材料、印刷电路制造、印刷电路等方向,能够解决难以降低制造成本、制造工序数增加等问题,达到实现制造成本、优异柔软性、良好耐弯折性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1、2

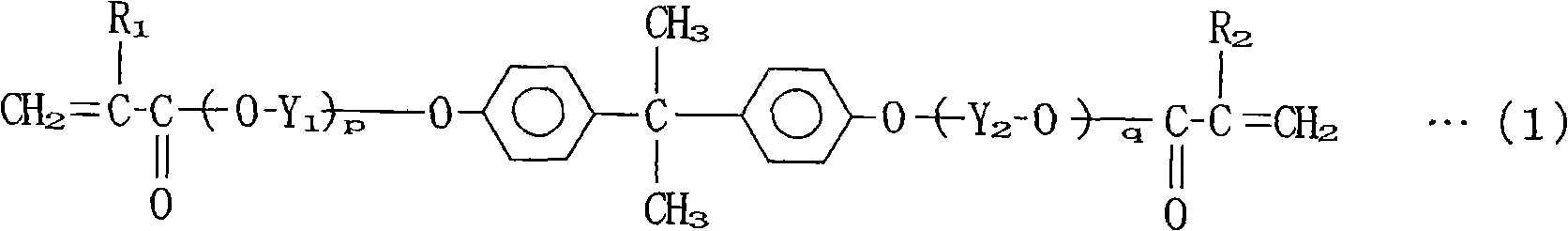

[0090] A photosensitive resin composition was prepared by mixing the components shown in Table 2 below in proportions (parts by weight) shown in the same table (in addition, the parts of polymers a to d in the table are solid content weight share).

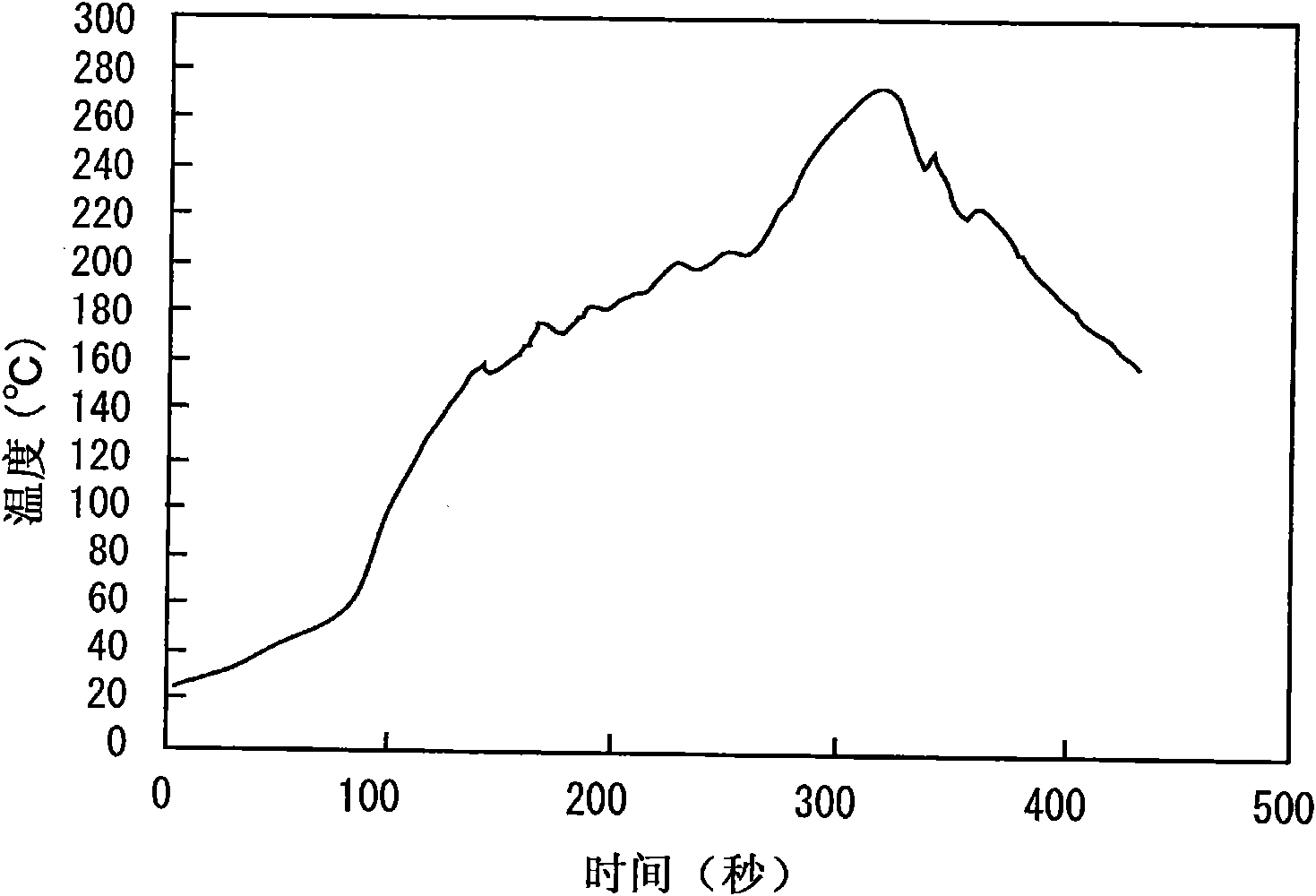

[0091] The tensile elongation at break and the 2% weight loss temperature of the cured product of the photosensitive resin composition thus obtained were measured according to the following criteria, and the results are shown in Table 2 below.

[0092] Tensile elongation at break

[0093] The photosensitive resin composition (solution) prepared above was coated on one side of a PET film with a thickness of 16 μm, and then dried (80° C.×30 minutes) to form a photosensitive resin composition film with a thickness of 25 μm after drying. . A cover film made of polypropylene with a thickness of 30 μm is attached to the photosensitive resin composition film, and a 250W ultra-high pressure mercury lamp is used at 500mJ / cm 2 UV rays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com