Development method of phonon crystal vibration reduction initial frequency of which is not higher than 200 Hz

A phononic crystal and frequency technology, which is applied in the development field of phononic crystals whose vibration reduction starting frequency is not higher than 200 Hz, can solve problems such as unfavorable application, and achieve the effects of strong designability and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

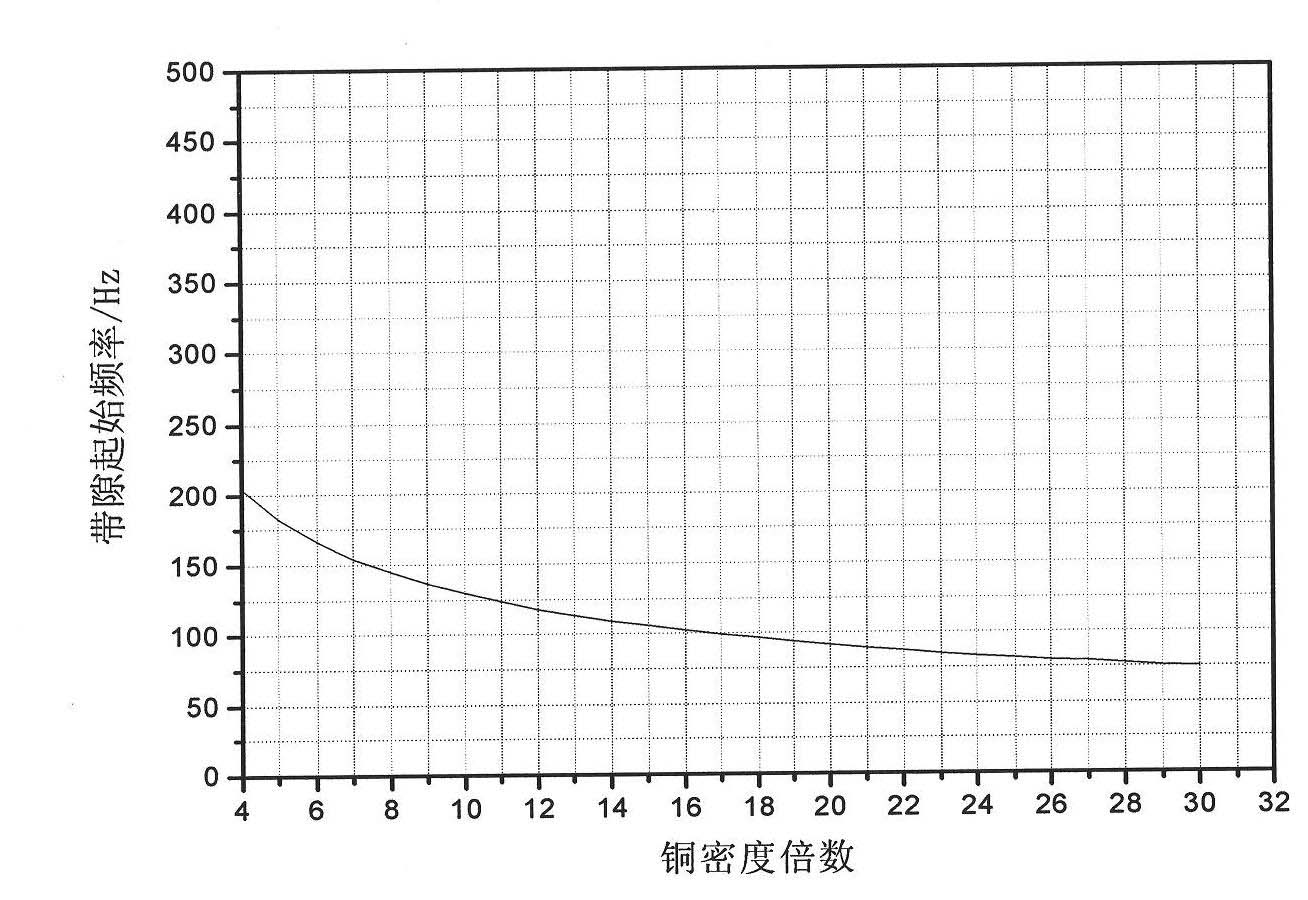

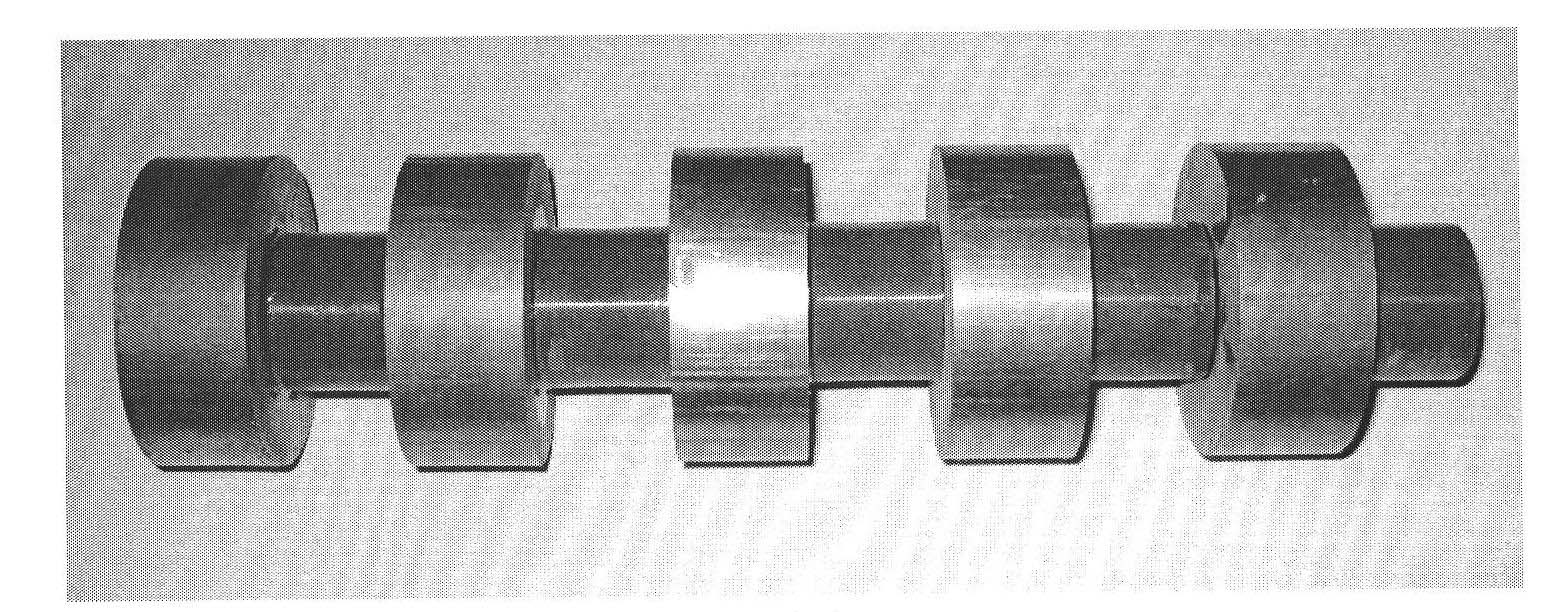

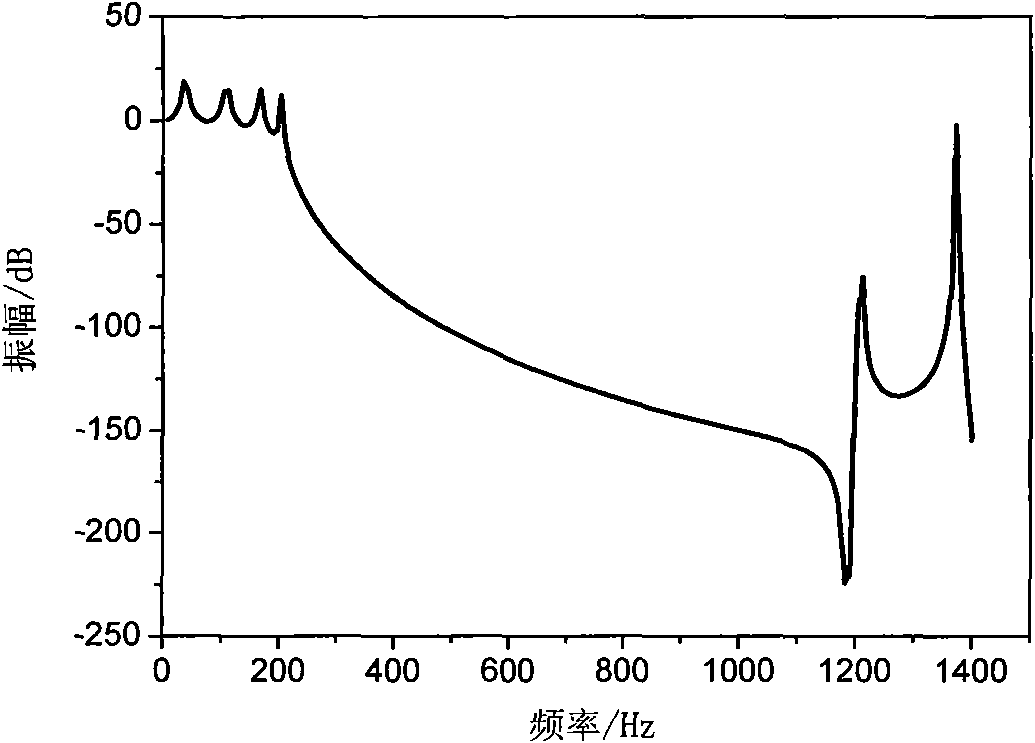

[0022] Example 1: Fabricate a phononic crystal with a vibration-damping starting frequency of 200 Hz.

[0023] The metal material is copper, and the rubber is silicon rubber. The measured material constants of the purchased materials are listed in Table 1. The period size is 0.04m. Calculate the height ratio of copper and rubber to be approximately 1 / 1, so the height of the copper block and the height of the rubber block are both 0.02m. Based on this condition, the equivalent density required to achieve 200Hz is 4 times the copper density (such as figure 1 shown), so the ratio of the rubber area to the area of the copper block is 1 / 4, and the radius of the rubber column is generally taken as 0.025m according to the load-bearing requirements of the application environment, so the radius of the copper column is 0.05m (4S 橡胶 ), the cross-section bonding of the two materials results in a phononic crystal with a vibration damping frequency starting at 200 Hz.

Embodiment 2

[0024] Implementation Example 2: Making a phononic crystal with the initial frequency of vibration reduction at 70-80 Hz.

[0025] The material is still copper and silicon rubber, and the period size of the phononic crystal is determined to be 0.04m. Calculate the height ratio of copper and rubber to be approximately 1 / 1, so the height of copper and rubber is 0.02m, and the radius of the rubber column is 0.0125m according to the equipment support requirements. The equivalent density needs to be 30 times the copper density, so the ratio of the rubber area to the copper block area is 1 / 30, so the radius of the copper column is 0.0685m (21S 橡胶 ). The cross-section bonding of the two materials results in a phononic crystal with a vibration damping frequency starting at 75 Hz.

[0026] Table 1 Material parameters

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com