Composite chestnut sauce and preparation process thereof

A preparation process, process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

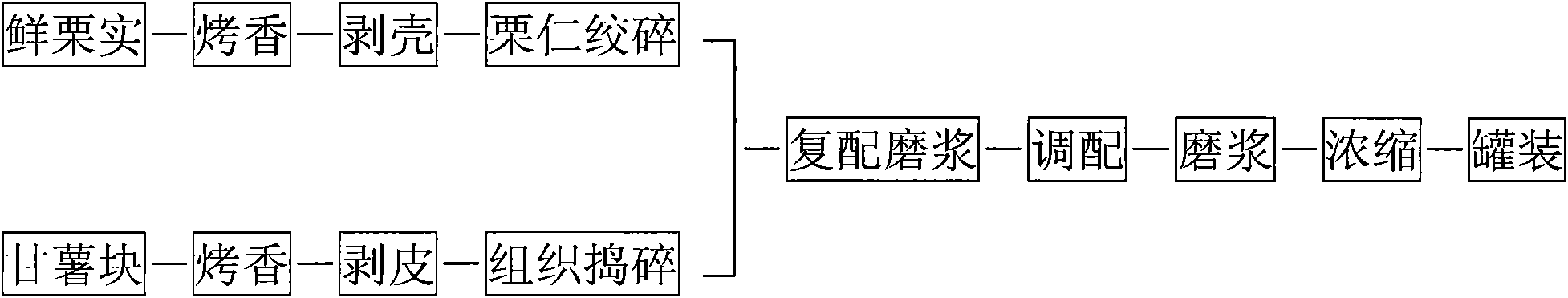

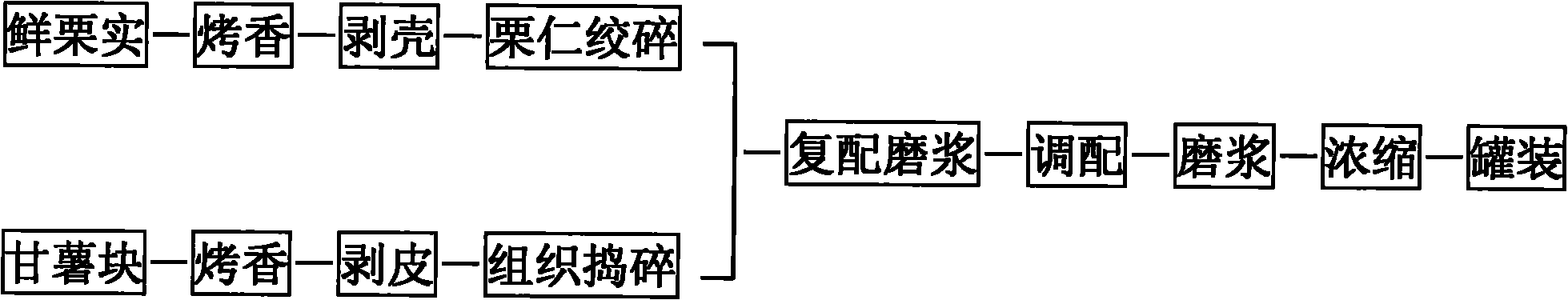

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Compound chestnut paste

[0032] Weigh 6kg of fresh chestnuts from Zunhua, Hebei Province, and process them with a chestnut scribe machine made by Beijing Forestry University. Put the scribed chestnuts into a sugar-fried chestnut machine, raise the temperature to 220°C, and stir-fry for 15 minutes. All the chestnuts will be cracked. , unloading spare.

[0033] Stir-fried and cracked chestnuts were spread out to dry in the natural wind, and after 5 minutes, the shells were manually peeled while they were still hot. The chestnut kernels and chestnut shells were separated, and the chestnut kernels were used to prepare compound chestnut sauce.

[0034] Wash 2kg of fresh sweet potatoes with red flesh, put them into a double-layer infrared oven, heat up to 250°C, and bake (enzyme-promoted fragrance) for 2 hours. Zhoupi, sweet potato with clean skin.

[0035] The chestnut kernels are minced by a grinder, and the particle diameter is ≤4mm.

[0036] Take by weigh...

Embodiment 2

[0040] Example 2 Compound chestnut sauce

[0041] Weigh 6.5kg of fresh chestnuts produced in Zhejiang, and process them with a chestnut scribing machine made by Beijing Forestry University. Put the processed chestnuts into a sugar-fried chestnut machine, heat up to 240°C, and stir-fry for 14 minutes. All the chestnuts are cracked and unloaded for later use. Stir-fried and cracked chestnuts were air-dried in the natural wind, and after 6 minutes, the shells were manually peeled while hot, and the chestnut kernels were used to prepare compound chestnut sauce.

[0042] Wash 2kg of fresh sweet potatoes with yellow flesh, put them into a double-layer infrared oven, heat up to 250°C, and bake for 2 hours. sweet potato.

[0043] The chestnut kernels are minced by a grinder, and the sweet potatoes with peeled skin are mashed to make sweet potato mash, and the particle diameter of the material is ≤4mm.

[0044] Take by weighing 4.5kg of the thinned chestnut kernel material, 1.5kg of...

Embodiment 3

[0047] Example 3 Compound chestnut jam

[0048] Weigh 3kg of fresh Chinese chestnuts from Zunhua, Hebei Province, and 3.5kg fresh Chinese chestnuts from Fujian Province, and process them with a chestnut scribing machine made by Beijing Forestry University. Put the slitted chestnuts into a sugar-fried chestnut machine, heat up to 230°C, and stir-fry them. Cook for 16 minutes, all the chestnuts are cracked, and unload for later use.

[0049] Stir-fried and cracked chestnuts are dried in the natural wind and then manually peeled while they are hot. The chestnut kernels are used to prepare compound chestnut sauce.

[0050] Wash 2kg of fresh sweet potatoes with red flesh, put them in a double-layer infrared oven, raise the temperature to 250°C, and roast them for 2 hours. sweet potato.

[0051] The chestnuts are minced by a grinder, and the peeled sweet potatoes are mashed to make sweet potato mash, and the particle diameter of the material is ≤4mm.

[0052] Take by weighing 2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com