Method for manufacturing paper container and paper container

A manufacturing method and paper-based technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problems of unreduced time consumption, insufficient bonding strength, and prolonged pressing time, etc. Achieve the effects of reducing the required time, fast manufacturing speed, and strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

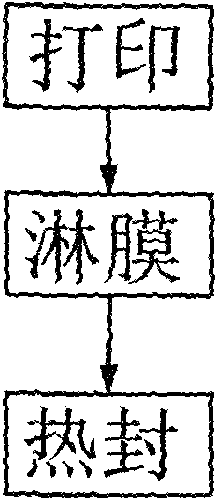

[0025] Please refer to figure 1 , the manufacture method of paper container of the present invention mainly comprises the following steps:

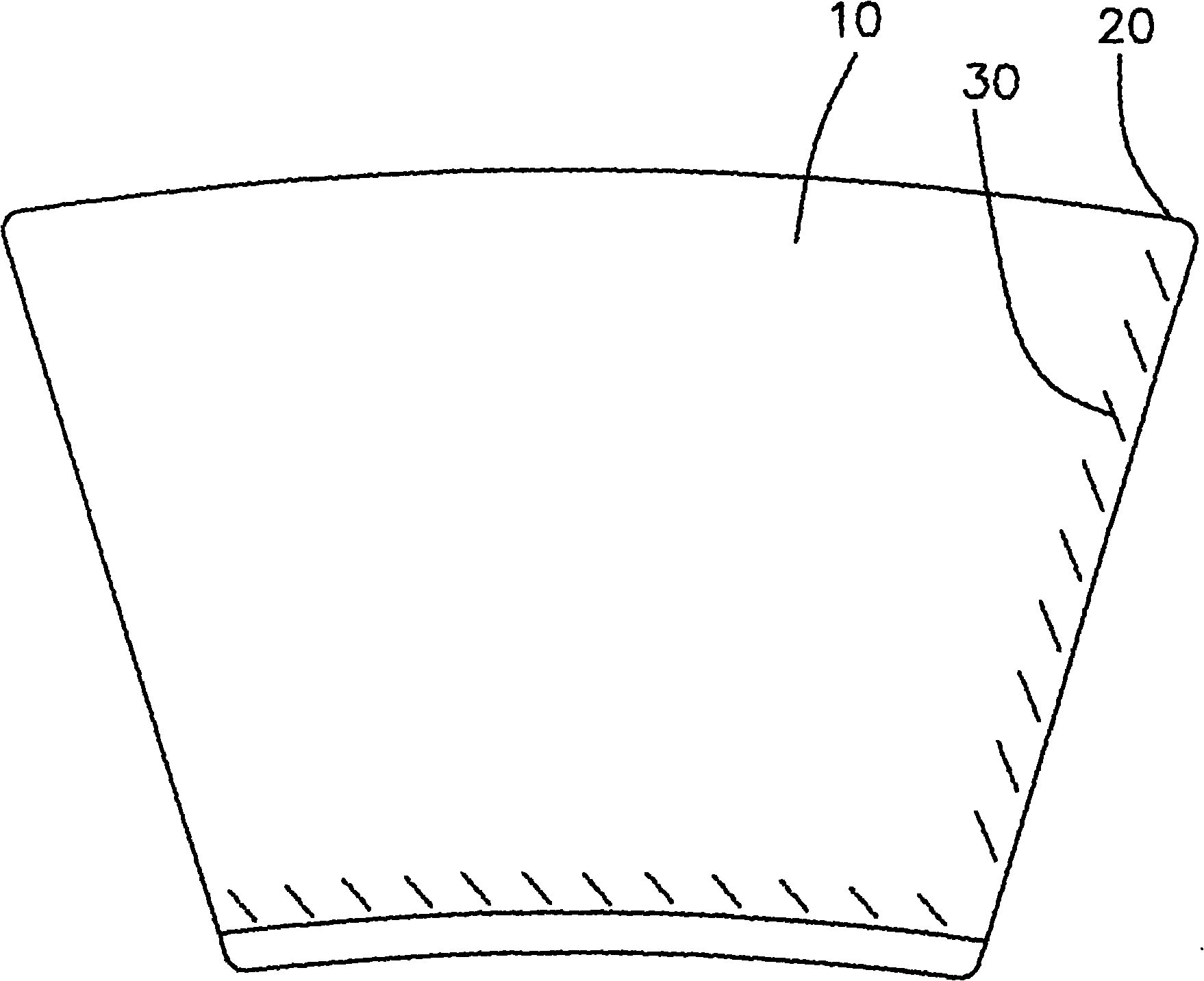

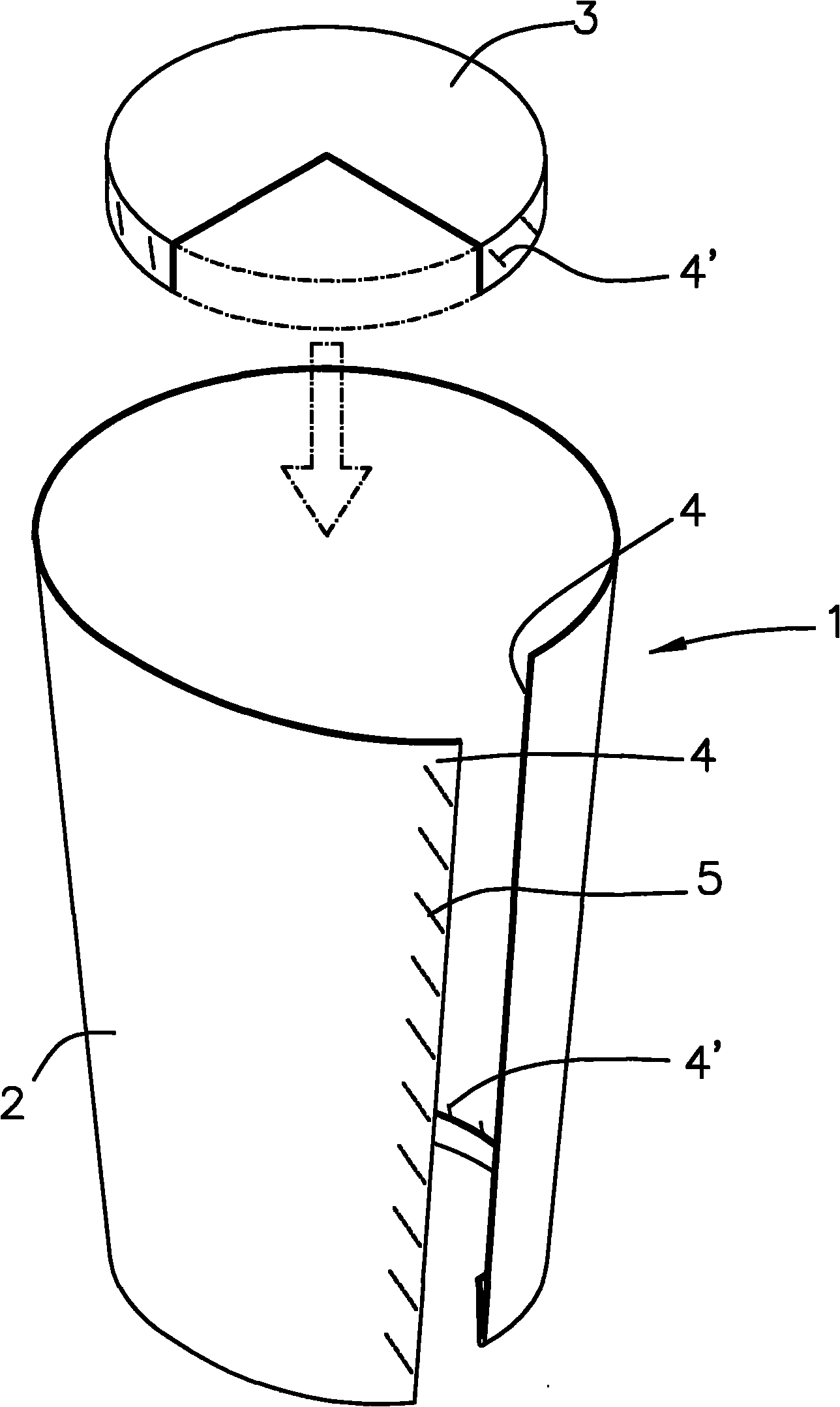

[0026] print: print as figure 2 A paper substrate 10 is shown, the paper substrate 10 has at least one pair of joint edges 20, and one or more non-penetrating grooves 30 are formed on at least one joint edge 20 of the pair of joint edges 20; The above-mentioned paper substrate refers to the plate-shaped paper container raw material made of paper or cardboard, and the paper substrate can be a continuous sheet of paper that has not been cut, or a plate-shaped substrate that has been pre-cut into a fan-shaped or other appropriate shape. In addition, for example, the pair of joint edges are located on different sides of the opposite sides of the paper substrate, so that when the paper substrate is subsequently wound into a cylindrical shape, the pair of joint edges can be correspondingly combined; and, as image 3 As shown, if it is desire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com