Magnesium alloy surface treatment method and preparation method of composite body of magnesium alloy and resin

A surface treatment, magnesium alloy technology, applied in the field of materials, can solve the problems of inability to meet product structural strength requirements, low bonding strength between magnesium alloy and resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

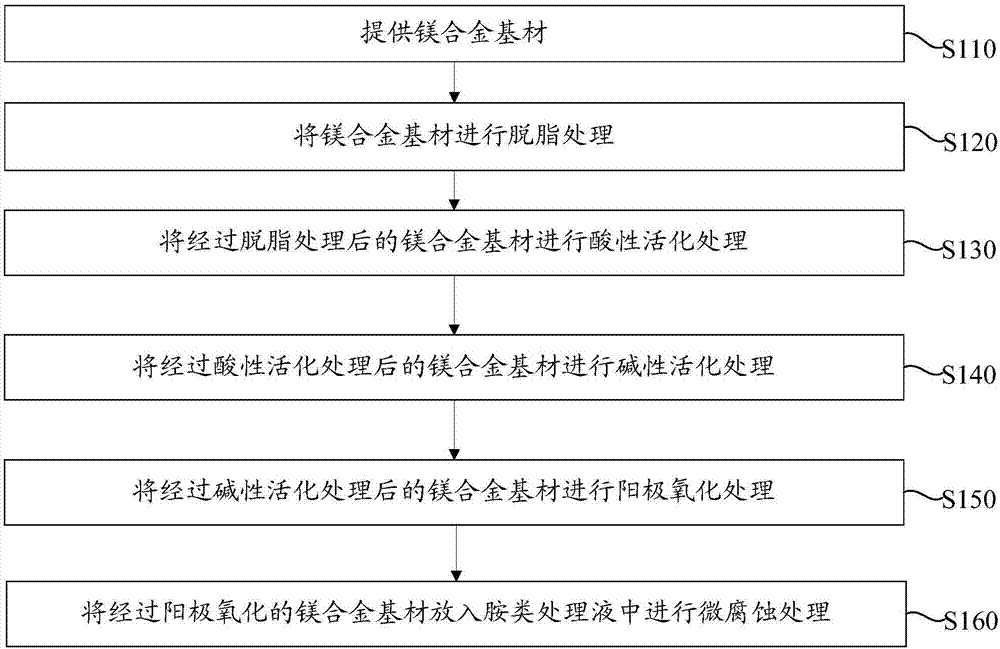

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing a composite of magnesium alloy and resin, including the magnesium alloy surface treatment method described in any of the above embodiments; or, using the magnesium alloy surface treatment method described in any of the above embodiments to achieve . As another example, the method for preparing the composite of magnesium alloy and resin adopts the magnesium alloy substrate after the micro-etching treatment in the magnesium alloy surface treatment method described in any of the above embodiments for subsequent treatment. . As another example, the preparation method of the composite of magnesium alloy and resin comprises the following steps:

[0049] Embedding the micro-etched magnesium alloy substrate into an injection molding mold, injecting resin into the surface of the magnesium alloy substrate, and forming a composite of magnesium alloy and resin in which the resin is integrated with the magnesium alloy after...

Embodiment 1

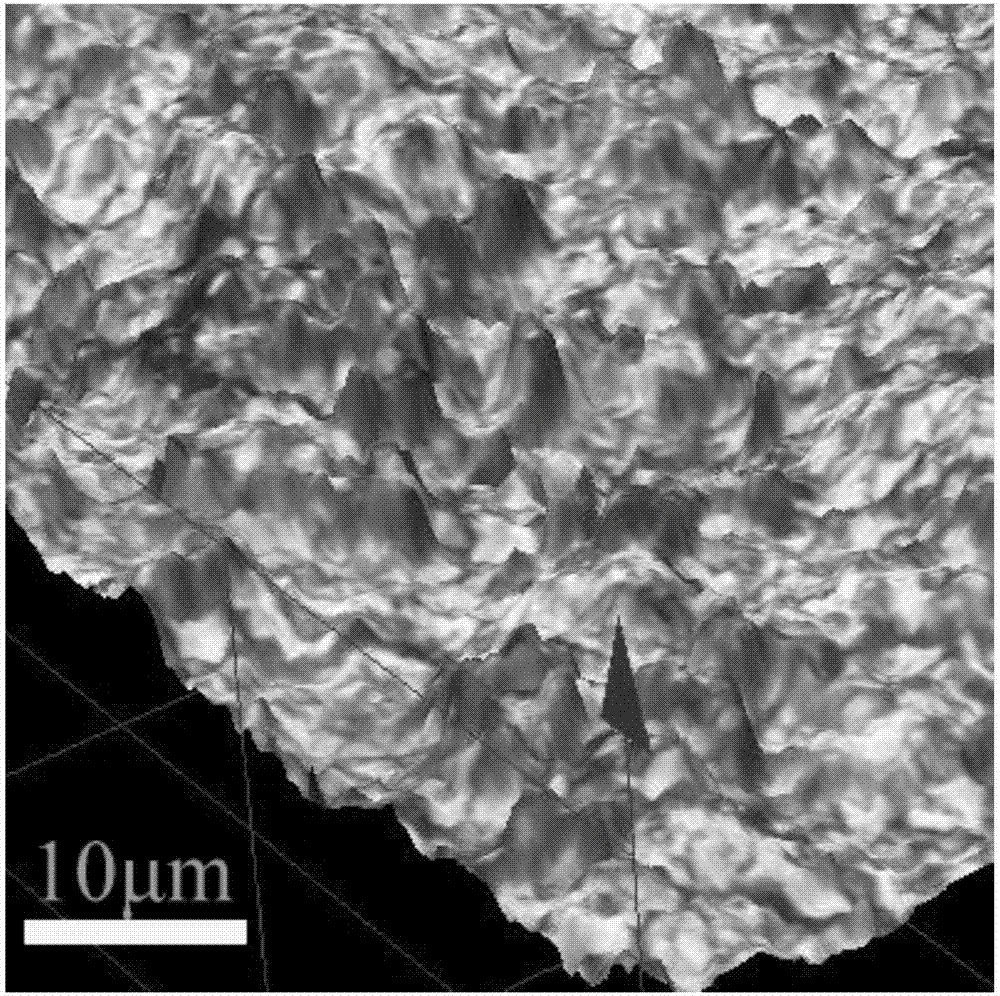

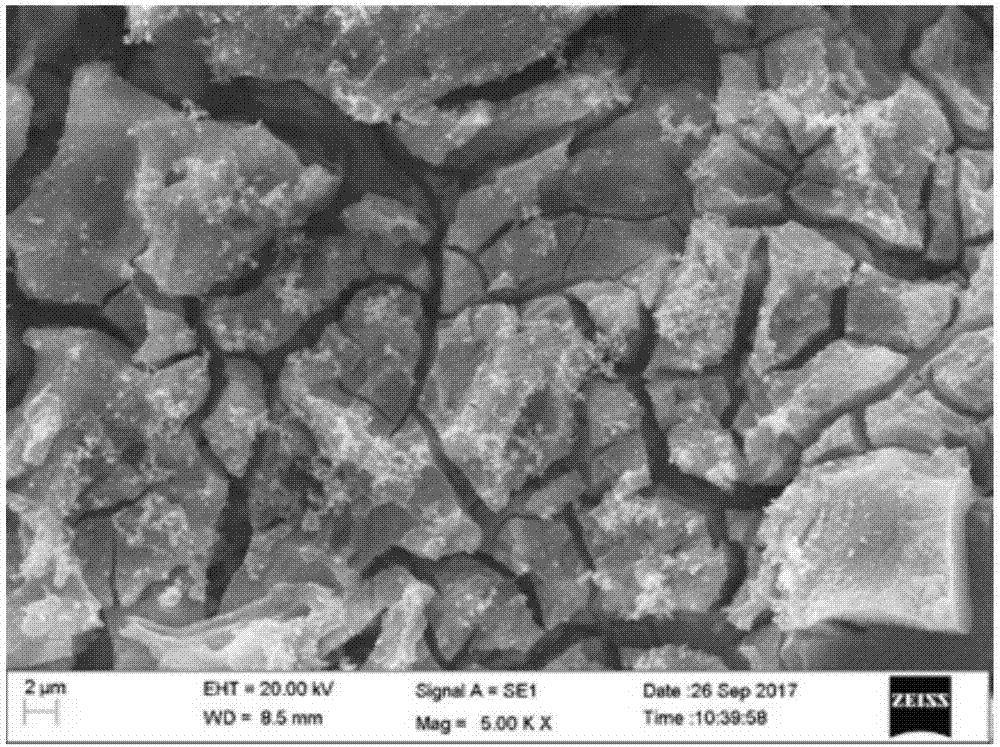

[0057] Using AZ91D magnesium alloy, first use a weak alkaline degreasing agent, ultrasonic degreasing for 5 minutes, temperature 60 ℃, to remove the oil on the surface of the magnesium alloy, wherein the degreasing agent components include: 20g / L sodium pyrophosphate, 15g / L tripolymer Sodium phosphate, 10g / L sodium gluconate, 3g / L OP emulsifier and 1g / L P60 sodium benzenesulfonate; take out the magnesium alloy and wash it with deionized water, then immerse the magnesium alloy in the acidic activator to activate 1 minute, the temperature is 60°C, to remove the oxide skin on the surface of the magnesium alloy and improve the surface state of the magnesium alloy. The acidic activator components are: 10g / L citric acid, 15g / L nitric acid and 15g / L sulfuric acid; after taking out the magnesium alloy Wash with deionized water, and then carry out alkaline activation treatment on the magnesium alloy to form micron-scale unevenness on the surface of the magnesium alloy, wherein the alkal...

Embodiment 2

[0059] Using AZ91D magnesium alloy, first use weak alkaline degreasing agent (degreasing agent composition: 20g / L sodium pyrophosphate, 15g / L sodium tripolyphosphate, 10g / L sodium gluconate, 3g / LOP emulsifier, 1g / LP60 benzene Sodium sulfonate), ultrasonic degreasing for 5 minutes at a temperature of 60°C, to remove the surface oil on the magnesium alloy; after taking out the magnesium alloy, wash it with deionized water, and then immerse the magnesium alloy in an acidic activator (acidic activator composition: 10g / In L citric acid, 15g / L nitric acid, 15g / L sulfuric acid), activate for 1 minute at a temperature of 60°C to remove the oxide skin on the surface of the magnesium alloy and improve the surface state of the magnesium alloy; wash the magnesium alloy with deionized water after taking it out , then magnesium alloy is carried out alkaline activation treatment (alkaline activator composition: the sodium hydroxide of 30g / L, the oxidizing agent of 25g / L, the complexing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com