Compound control method for fast and accurate tracking control of maximum power point of photovoltaic power generation system

A photovoltaic power generation system and maximum power point technology, which is applied in the directions of optical radiation generators, control/regulation systems, generators/motors, etc., which can solve the problem of poor MPPT control accuracy and control adaptability, inability to track maximum power, and high control system requirements. Advanced problems, to achieve the effect of fast tracking, economical and reliable, and improve tracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

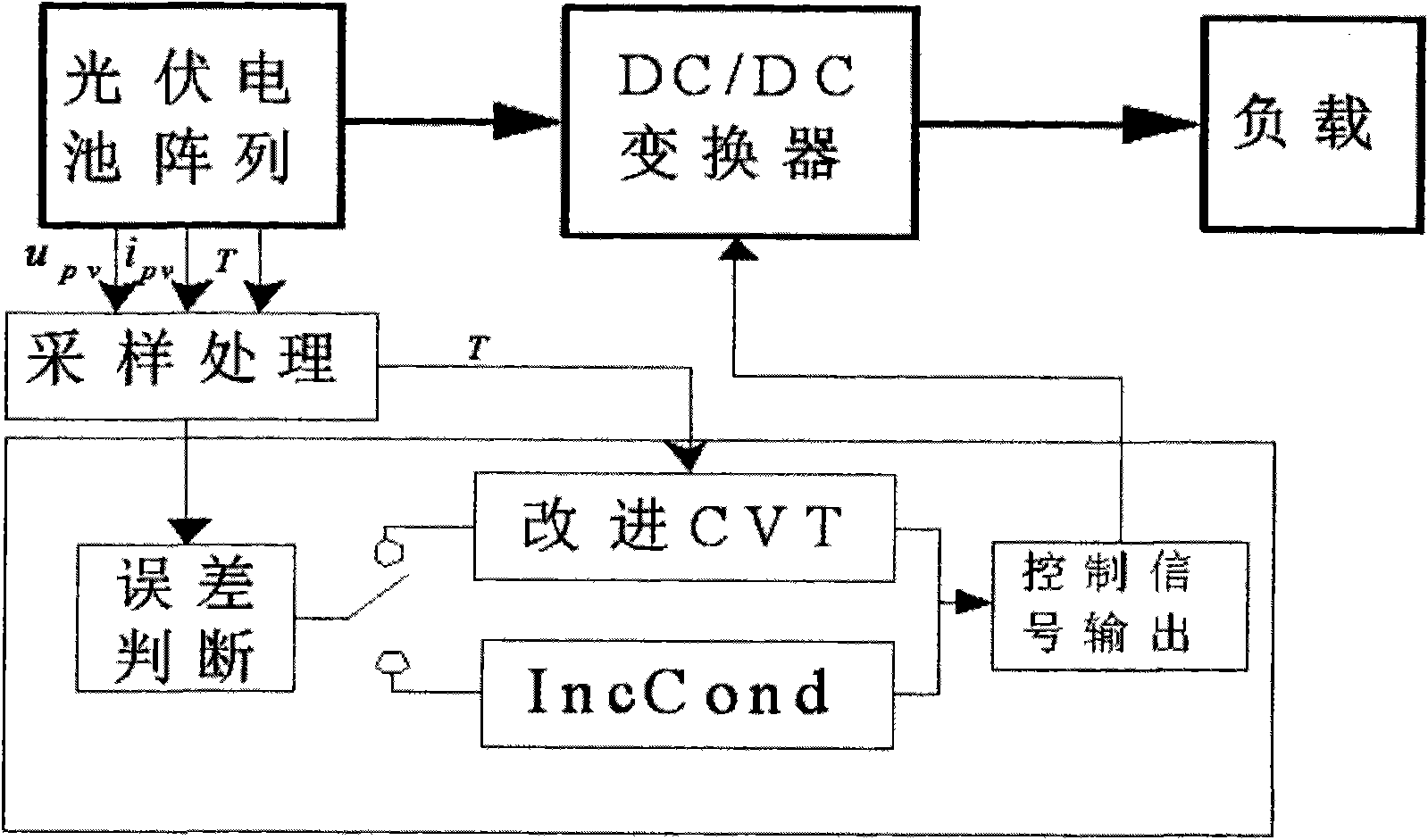

[0013] Such as figure 1 Shown is the block diagram of the control system of the present invention. In the figure, the working parameters output voltage, current and working temperature of the photovoltaic module are input to the A / D conversion interface of the control chip MCU after being sampled and processed by the circuit. Comparing the previous moment, the power error is obtained. If the error is greater than or equal to the set threshold, the improved constant pressure control method is selected, and the parameters are corrected in combination with the collected working temperature; if the error is smaller than the set threshold, the The admittance incremental method is selected for control; the control output changes the register value of the PWM signal generator, thereby changing the duty cycle, adjusting and controlling the parameters of the DC / DC conversion circuit, and realizing maximum power tracking control.

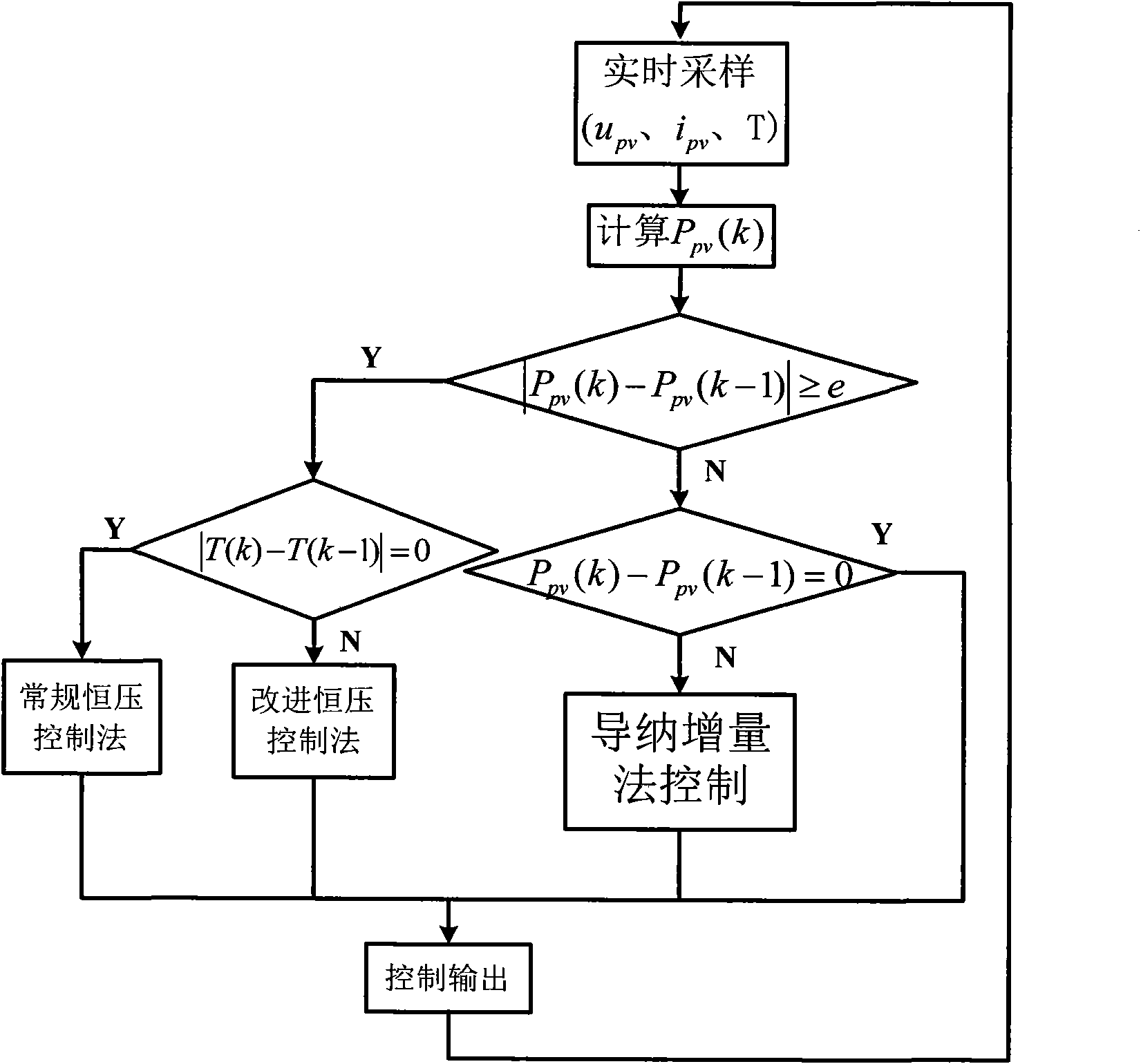

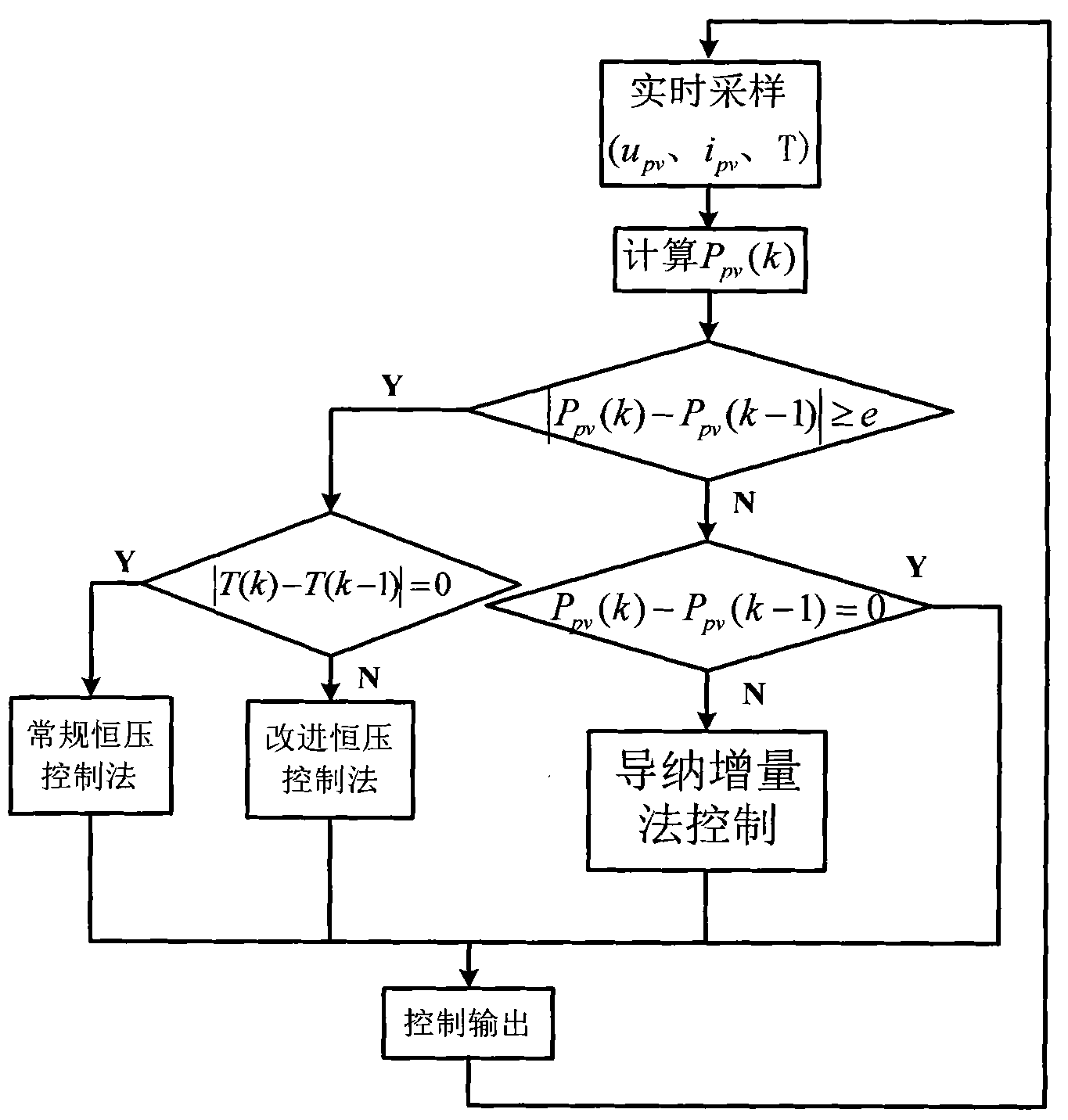

[0014] Such as figure 2 As shown, the specific imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com