Capsule detecting machine

A capsule inspection machine and capsule technology, which is applied in the direction of optical testing for flaws/defects, sorting, etc., can solve problems such as image data distortion, falling on the conveyor belt, uneven surface light, etc., to improve the removal speed and accuracy, The effect of low misjudgment rate and wide adaptability of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

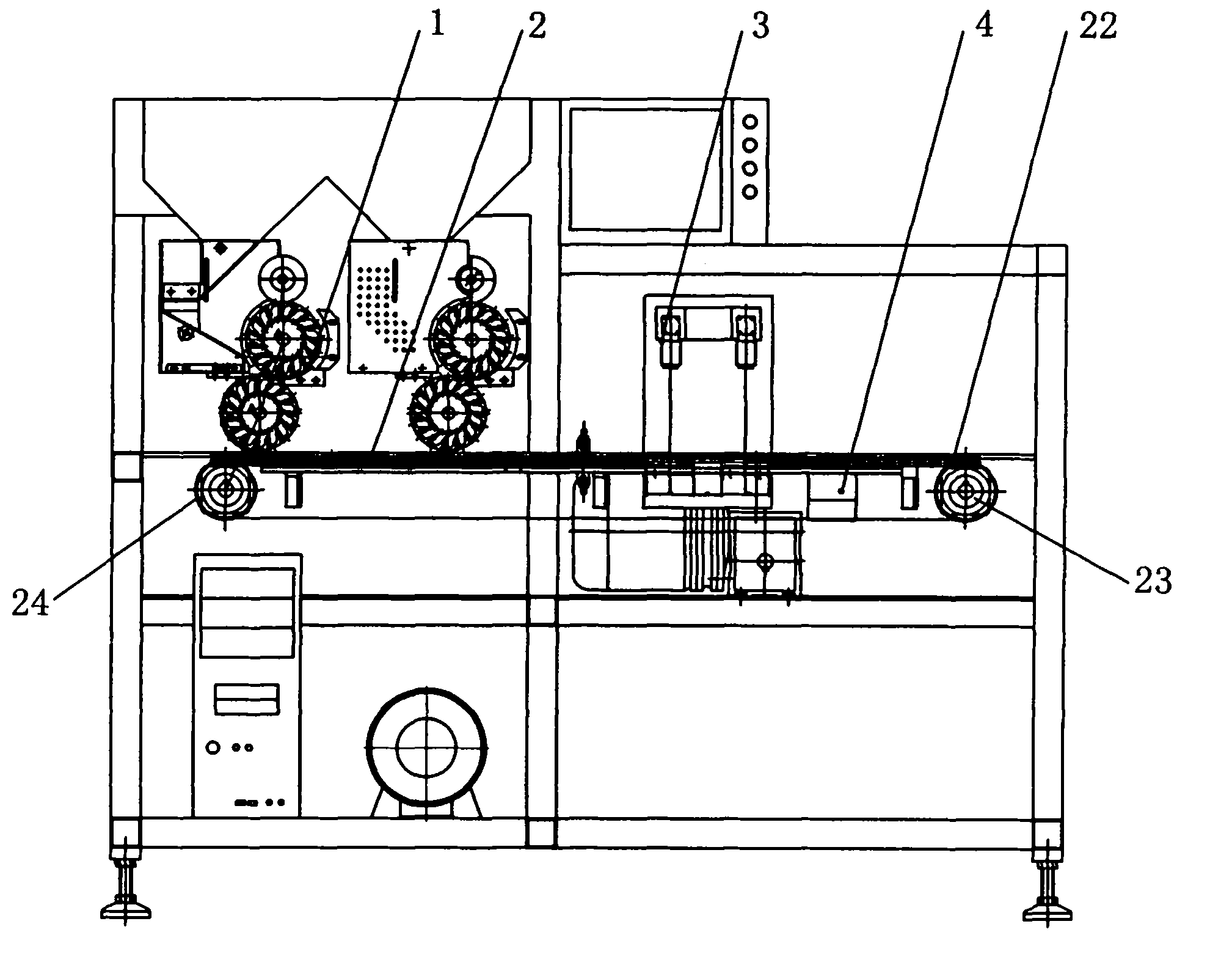

[0016] An embodiment of the present invention see figure 1 , the capsule inspection machine includes a positioning arrangement device 1 , a conveying device 2 , an image detection device 3 and a rejecting device 4 .

[0017] The positioning and arranging device 1 can be used in the hollow hard capsule production equipment or the positioning and arranging device in the hard capsule preparation filling equipment in the prior art. The positioning and arranging device 1 is installed at the front end of the conveying device 2 , and the positioning and arranging device 1 positions and arranges the capsules or capsule preparations, and transports them neatly and one by one to the through hole of the detection template 21 of the conveying device 2 .

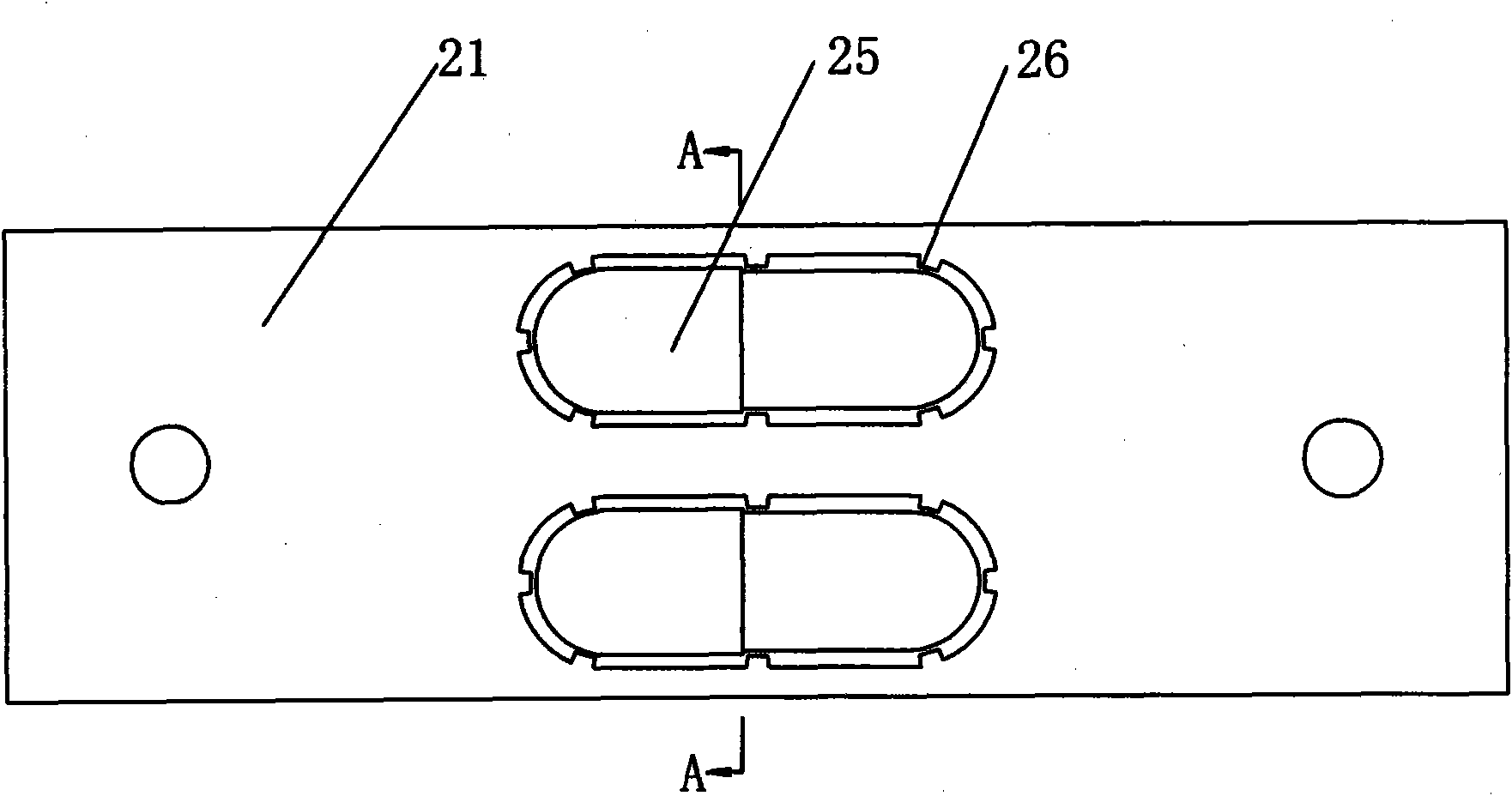

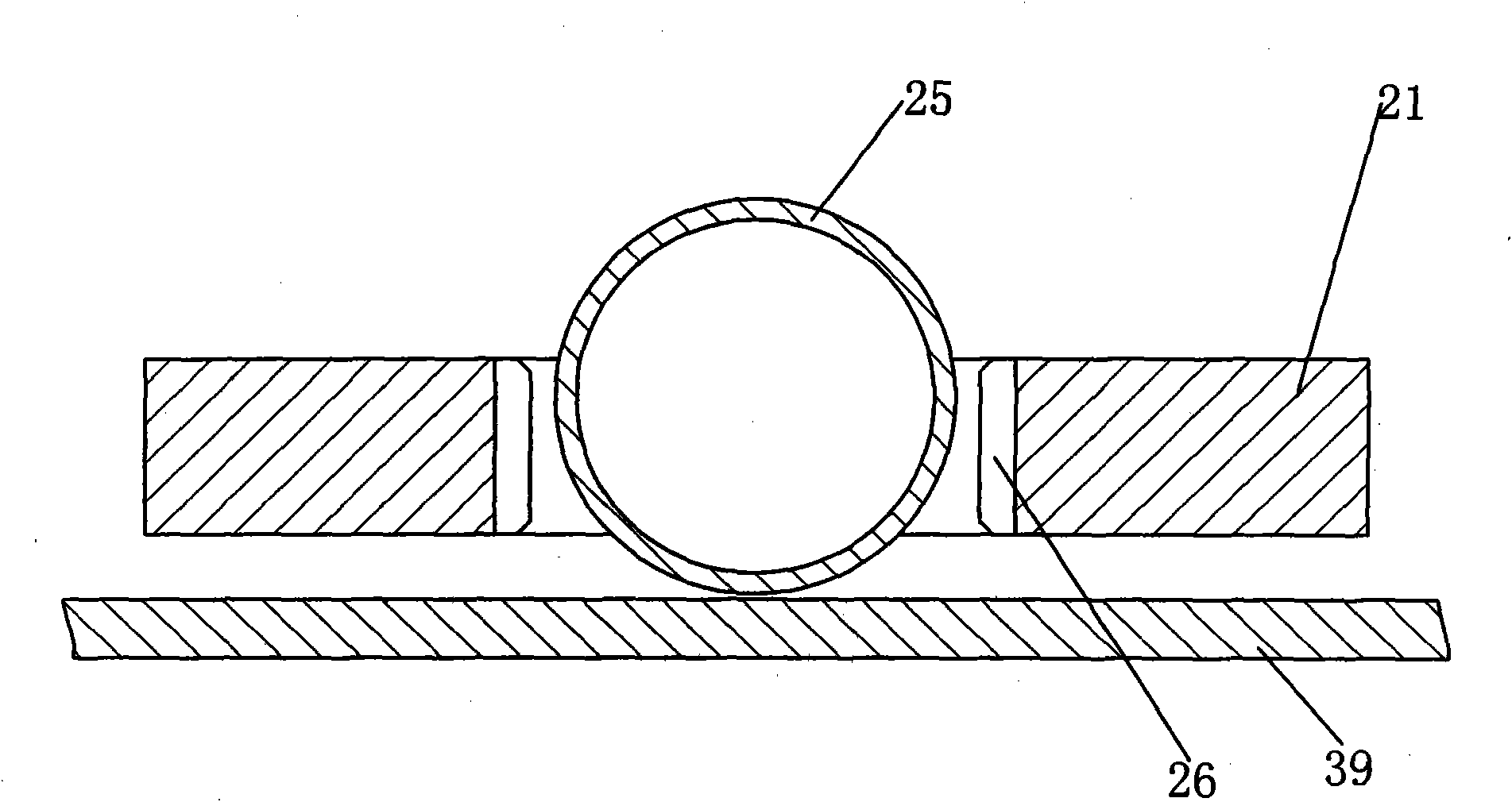

[0018] see figure 2 and image 3 , the conveying device 2 includes a conveying belt 22 linked by detection templates 21, and the conveying belt 22 circulates on transmission wheels 23 and 24. Each detection template 21 may have one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com