Novel intelligent embedded type electric upsetter control system for air valve production

An embedded, electric upsetting machine technology, applied in forging presses, forging presses, manufacturing tools, etc., can solve the problems of low intelligence level of electric upsetting machines, narrow process adaptability, simple operation interface, etc., to achieve real-time closed-loop automatic Control, improve the real-time control, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

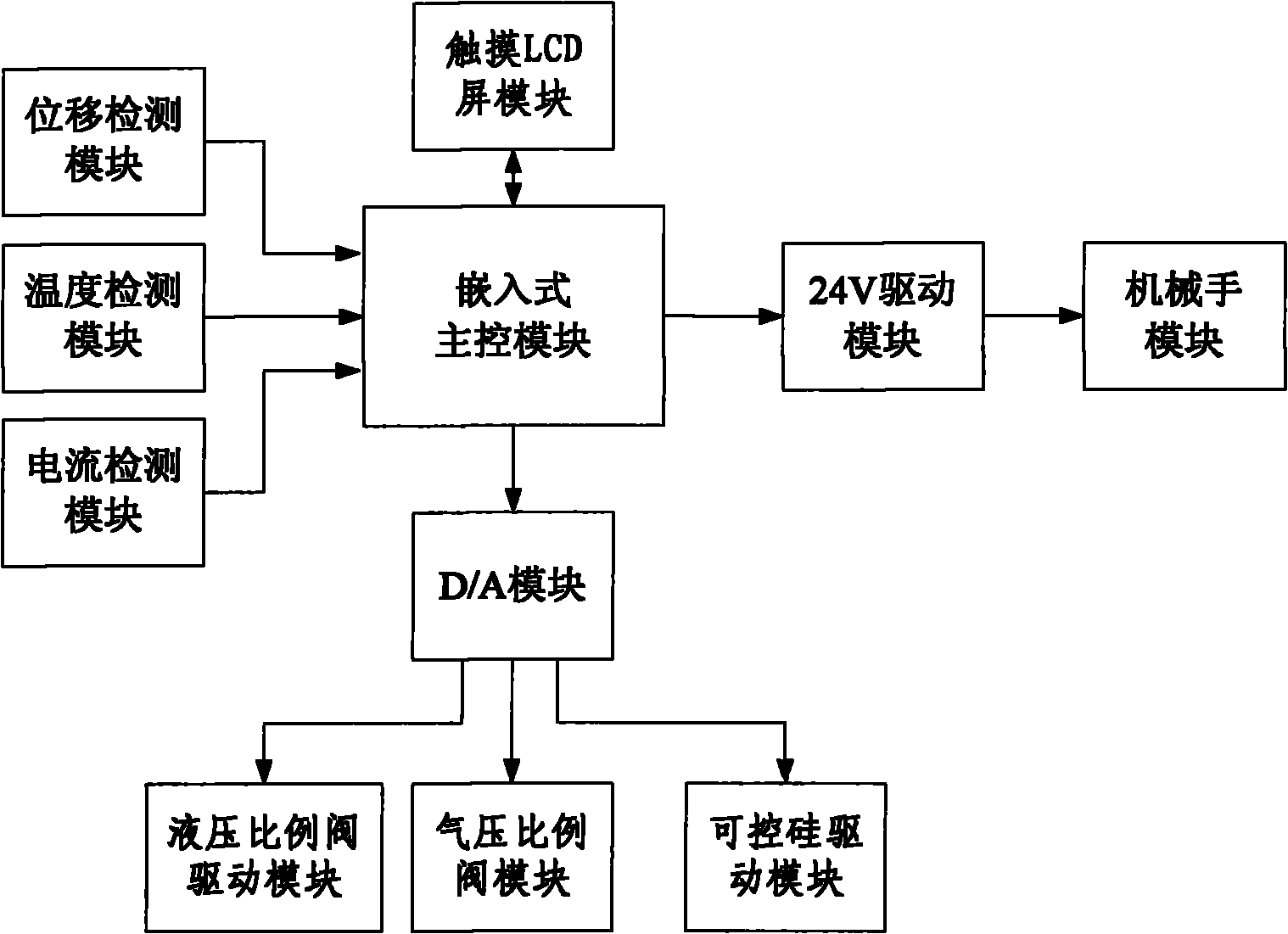

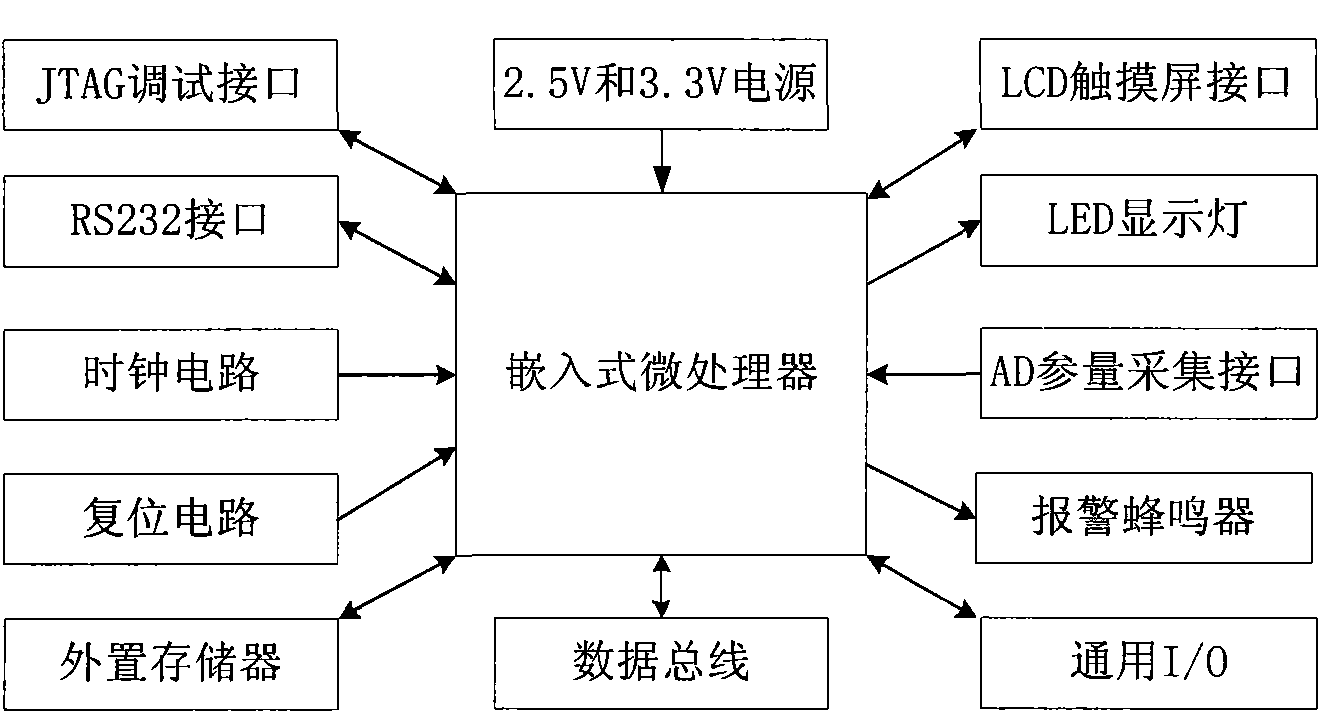

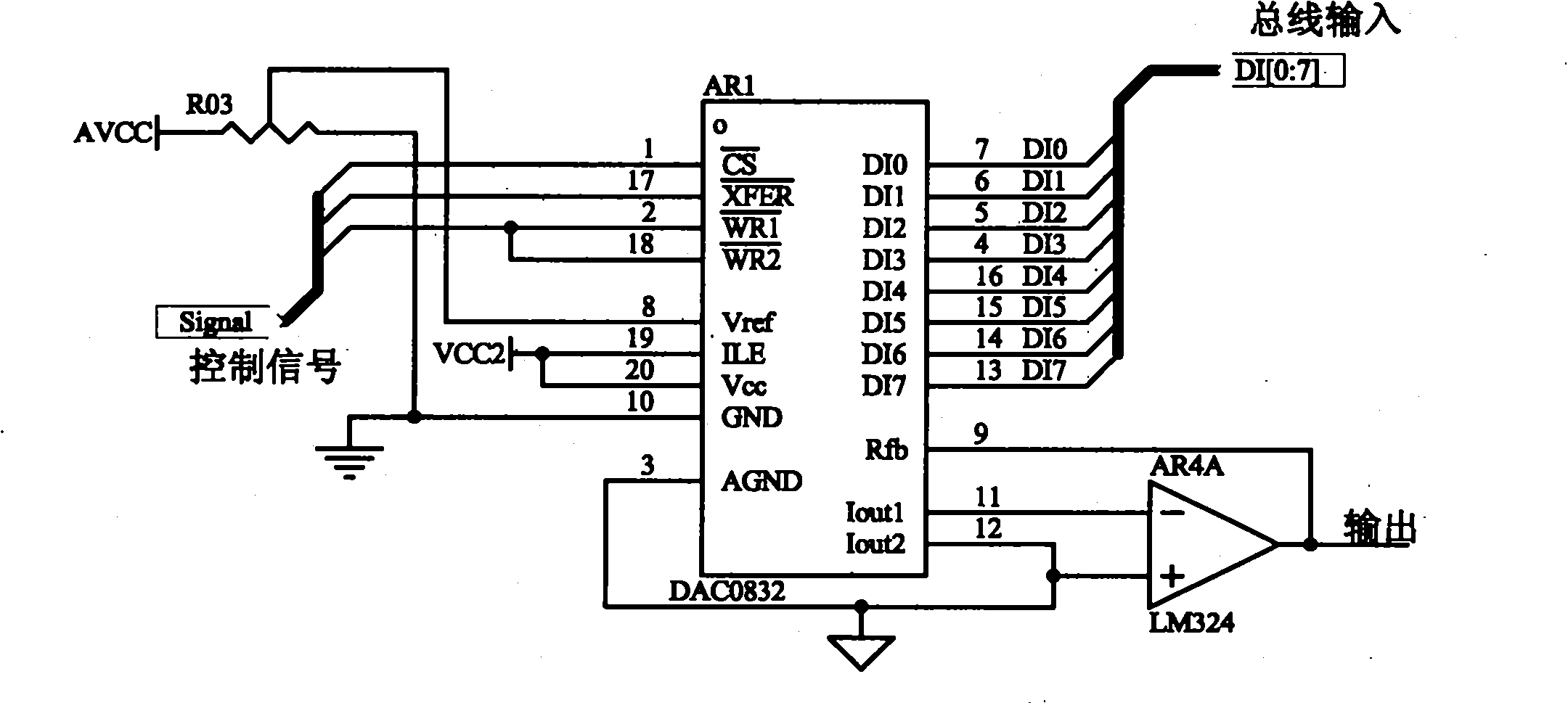

[0014] The structure of the present invention is shown in the structural diagram, including: an embedded main control module (1), a touch LCD screen module (2) for parameter input and display, and a D / A module (for controlling heating current and upsetting pressure) 3), the 24V drive module (4) used to drive the solenoid valve, the hydraulic proportional valve drive module (5) used to drive the hydraulic proportional valve, the pneumatic proportional valve module (6) used for air pressure control, and used for transformer control The thyristor drive module (7), the current detection module (8) for heating current detection, the temperature detection module (9) for heating temperature detection, the displacement detection module (10) for displacement detection, and useful The solenoid valve module (11) used in the action control of the manipulator. All detection modules: current detection module (8), temperature detection module (9), and displacement detection module (10) are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com