Method for recycling crystalline alkali in unrefined solution full confluence production by sintering process

A technology of sintering method and crystallization alkali, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of increased energy consumption and increased labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

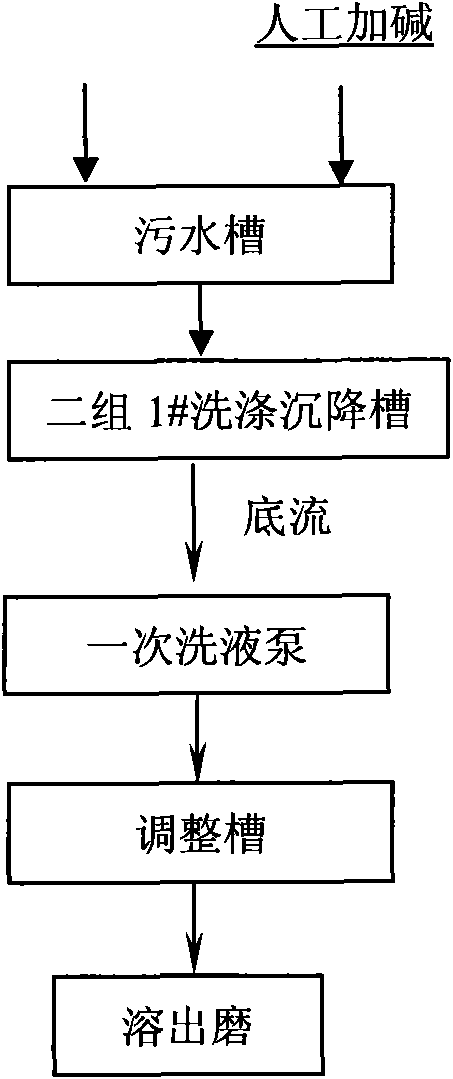

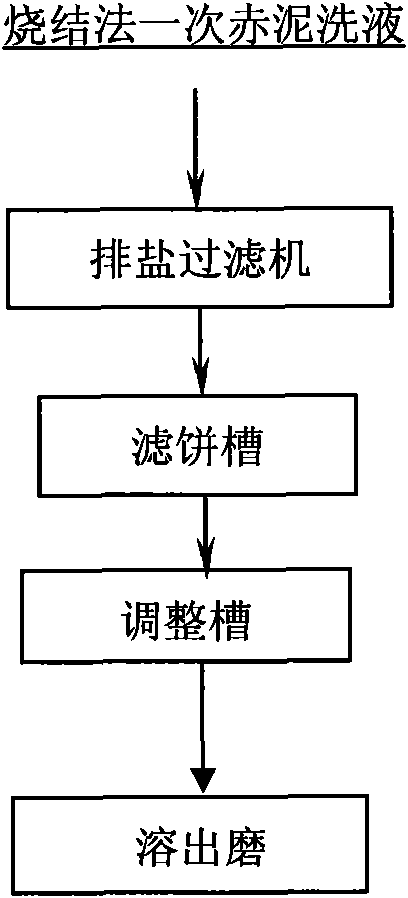

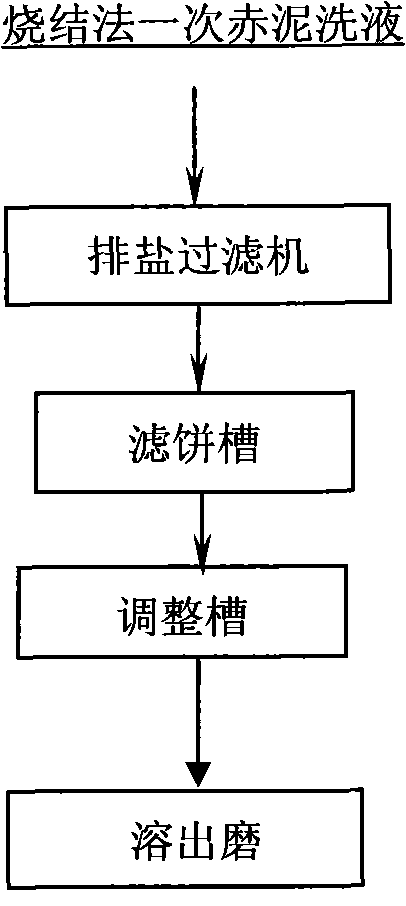

Method used

Image

Examples

Embodiment 1

[0011] The liquid-solid ratio of primary washing liquid and crystallization alkali completely dissolved is 10:1m 3 / t, once washing liquid dissolves the crystallization alkali temperature 50 ℃, decrystallization alkali time, 10min solution composition Na 2 o C 25.50g / l;

Embodiment 2

[0013] The liquid-solid ratio of primary washing liquid and crystallization alkali completely dissolved is 10:1m 3 / t, the temperature of the crystallization alkali dissolved in the primary wash solution is 70°C, the time of the crystallization alkali solution, and the solution component Na is 10min 2 o C 32.6g / l;

Embodiment 3

[0015] The liquid-solid ratio of primary washing liquid and crystallization alkali completely dissolved is 2:1m 3 / t, once washing liquid dissolves the crystallization alkali temperature 50 ℃, decrystallization alkali time, 10min solution composition Na 2 o C 106.1g / l;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com