Resin composition for encapsulating optical semiconductor element

A technology of optical semiconductor and composition, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of not being able to claim to provide thermal shock resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

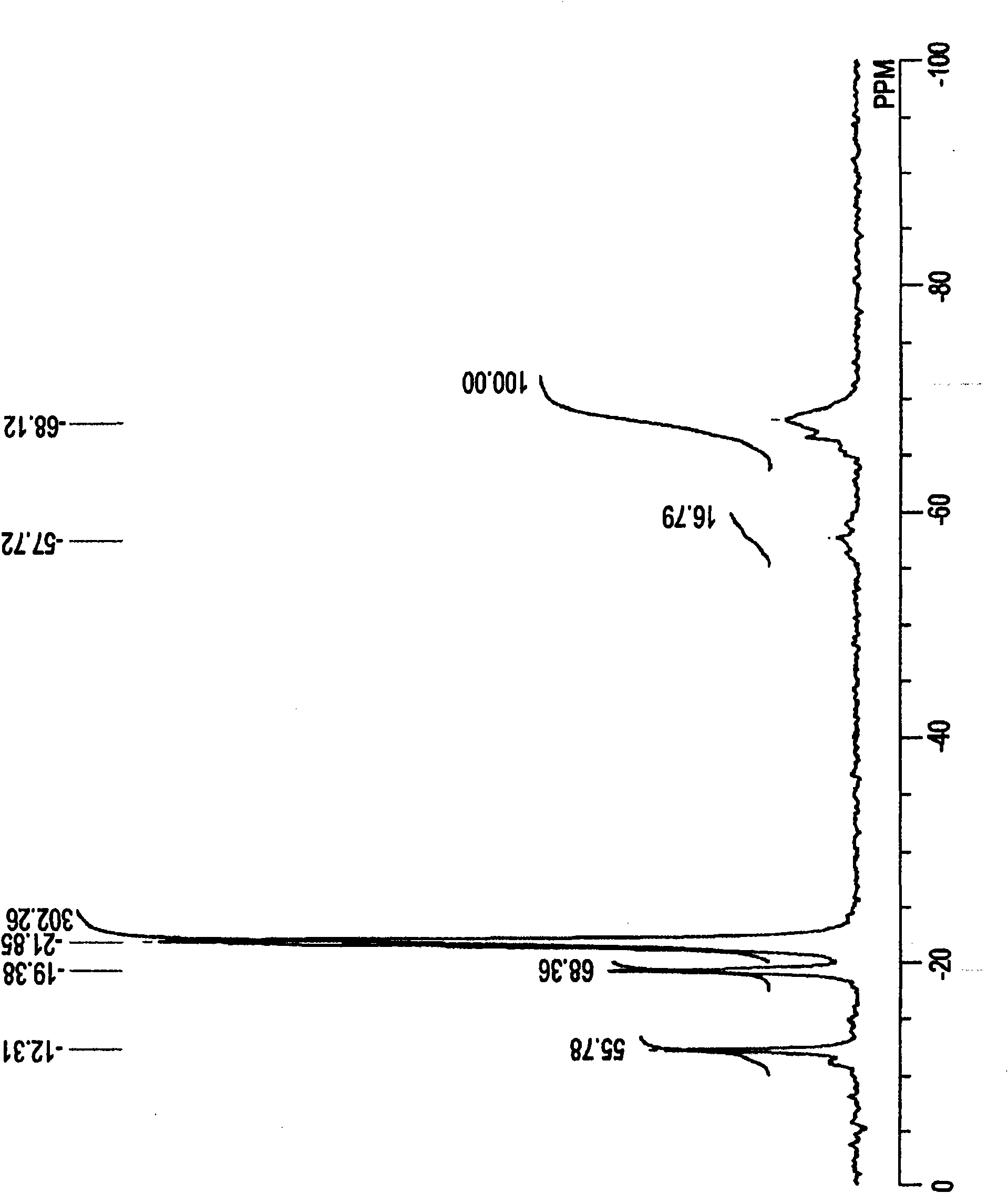

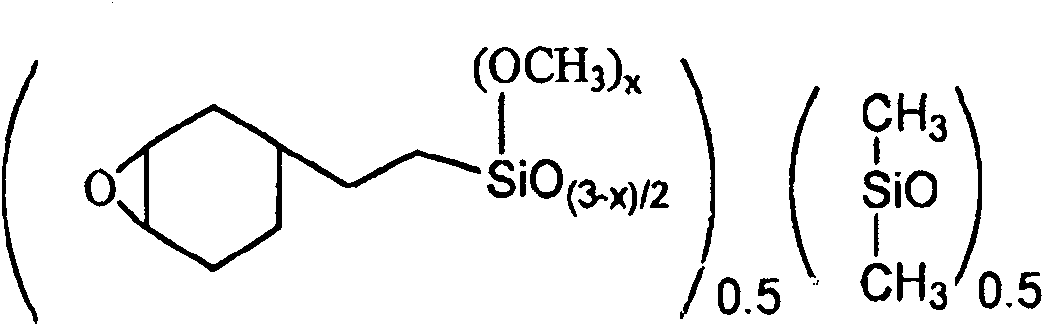

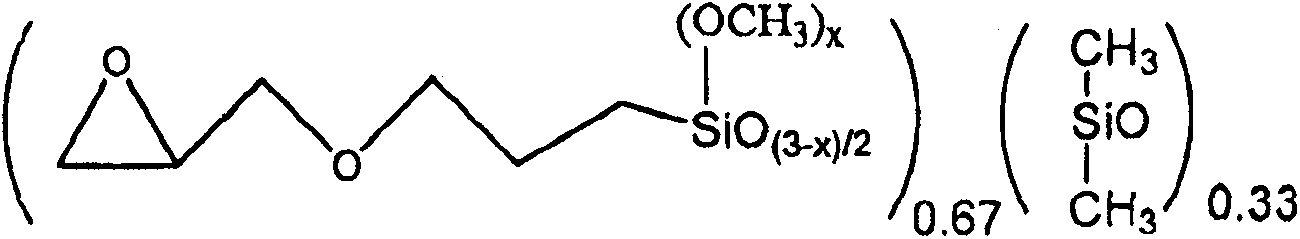

Image

Examples

Embodiment 1~6, comparative Embodiment 1

[0104]

[0105] Compositions having the formulations shown in Table 1 were prepared using the resins obtained above. In Table 1, for each component other than the curing agent, the listed numbers represent "parts by mass". Other components used in the composition are listed below.

[0106] (C) Curing agent: 4-methylhexahydrophthalic anhydride (RIKACID MH, manufactured by New Japan Chemical Co. Ltd.)

[0107] (D) curing catalyst: season Salt (UCAT5003, manufactured by San-Apro Ltd.)

[0108] Silane coupling agent: 3-mercaptopropylmethyldimethoxysilane (KBM-802, manufactured by Shin-Etsu Chemical Co., Ltd.)

[0109] Epoxy resin: 3,4-epoxycyclohexylmethyl 3',4'-epoxycyclohexanecarboxylate (CELLOXIDE 2021P, manufactured by Daicel Chemical Industries, Ltd.)

Embodiment 1

[0111] To obtain the composition, the following components were melt mixed: 80 parts by mass of resin 1, 20 parts by mass of resin 4, an amount of curing agent providing 1 mol of anhydride groups for every 1 mol of all epoxy groups in resins 1 and 4 and for each 100 parts by mass of the mixture of resins 1 and 4 and curing agent, 0.39 parts by mass of curing catalyst and 0.25 parts by mass of silane coupling agent. Melt mixing was carried out by first melting the curing agent and curing catalyst in an oven at 60° C., and then mixing with other components at 2,000 rpm for 1 min using a mixer (product name: Thinky Mixer, manufactured by Thinky Corporation), and then at 2,200 rpm. Degassing at rpm for 1min.

Embodiment 2

[0113] To obtain the composition, melt mix the following components in the same manner as in Example 1: 80 parts by mass of resin 1, 20 parts by mass of resin 5, in an amount of providing 1 mol of anhydride for every 1 mol of all epoxy groups in resins 1 and 5 Group curing agent and 0.39 parts by mass curing catalyst and 0.25 parts by mass silane coupling agent per 100 parts by mass of the mixture of resins 1 and 5 and curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com