Aluminum alloy for automobile body of automobile and plate manufacturing method thereof

A technology of aluminum alloy sheet and automobile body, applied in the field of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

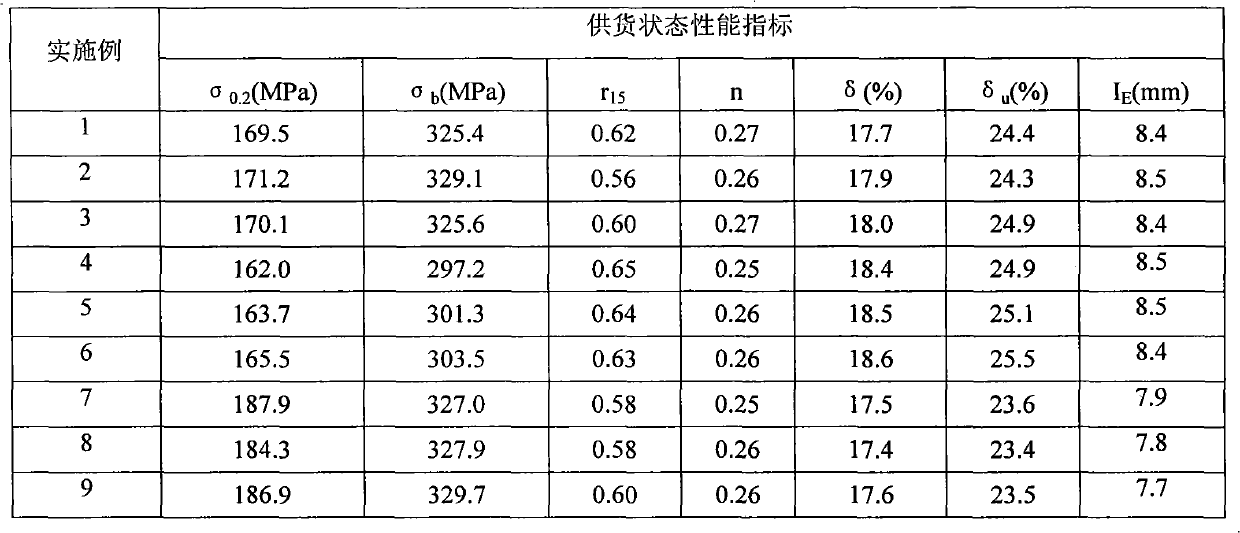

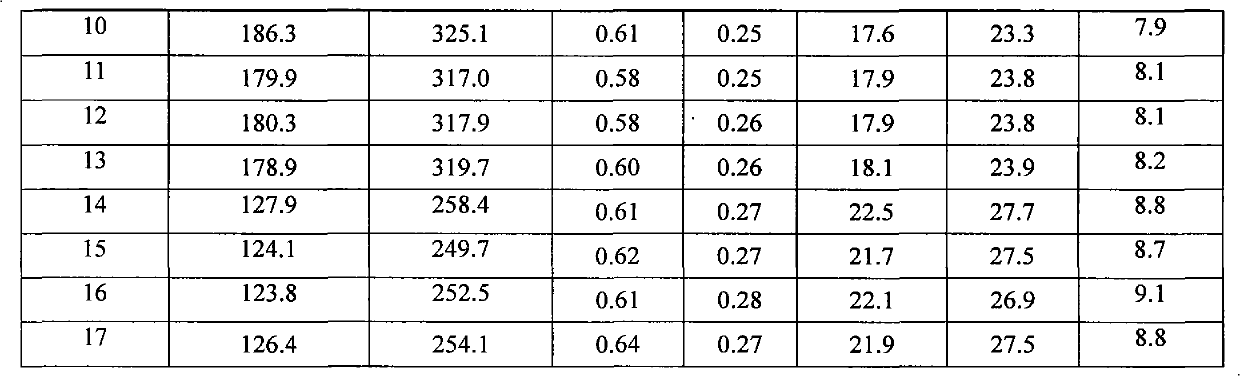

Examples

Embodiment 1

[0016] Cut a 100mm long ingot from the alloy 1# flat ingot for implementing the invention, put it into a circulating air furnace at room temperature, heat it up to 100°C for 21 hours with the furnace, then heat it up to 550°C for 24 hours, take it out of the furnace and air cool it, cut the head and mill it After surface reheating to 440°C to start rolling, first rolling 3 passes along the width direction of the slab, and then rolling along the length direction of the slab to form a 6mm thick plate, the final rolling temperature is 330°C. After cutting the hot-rolled plate to length, it is directly annealed at 440°C×0.5h, and finally cold-rolled into a thin plate with a thickness of 1.0mm. The thin plate was solution treated in a salt bath furnace for 540 ° C × 10 min and then water quenched, then placed in a drying oven for a pre-aging treatment of 170 ° C × 5 min within 1 min, and then parked at room temperature for 2 weeks before tensile and cupping tests.

Embodiment 2

[0018]Cut a 100mm long ingot from the alloy 1# flat ingot for implementing the invention, put it into a circulating air furnace at room temperature, heat it up to 450°C for 6h with the furnace, then heat it up to 550°C for 24h, take it out of the furnace, air cool, cut the head and mill Reheat to 440°C after surface rolling, first roll along the width direction of the slab for 3 passes, and then roll along the length direction of the slab to form a 5mm thick plate, the final rolling temperature is 325°C. After cutting to length, it is directly annealed at 420°C for 1h, and finally cold-rolled into a thin plate with a thickness of 0.9mm. The sheet was solution treated in a salt-bath furnace for 550°C×7min, then quenched at room temperature for 8h, then placed in a drying oven for pre-aging treatment at 190°C×7min, and then stretched and stretched after 2 weeks at room temperature. Cupping test.

Embodiment 3

[0020] Cut a 100mm long ingot from the alloy 1# flat ingot for implementing the invention, put it into a circulating air furnace at room temperature, heat it up to 280°C for 16 hours with the furnace, then heat it up to 550°C for 24 hours, take it out of the furnace and air cool it, cut the head and mill it After surface reheating to 450°C to start rolling, firstly rolling 3 passes along the width direction of the slab, and then rolling along the length direction of the slab to form a 4mm thick plate, the final rolling temperature is 310°C. After cutting the hot-rolled plate to length, it is directly annealed at 410°C×2h, and finally cold-rolled into a thin plate with a thickness of 0.7mm. The sheet is subjected to solution treatment water quenching at 545°C×7min in a salt bath furnace and parked at room temperature for 48h, then put into a drying oven for pre-aging treatment at 240°C×3min, and then stretched at room temperature for 2 weeks and cupping test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com