Internal division type laminated column frame-bilayer steel plate concrete combined shear wall and manufacturing method thereof

A steel plate concrete and combined shear wall technology, applied to walls, building components, and earthquake resistance, to achieve the effects of improving seismic performance, improving deformation capacity and ductility, and improving thermal insulation, energy saving and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

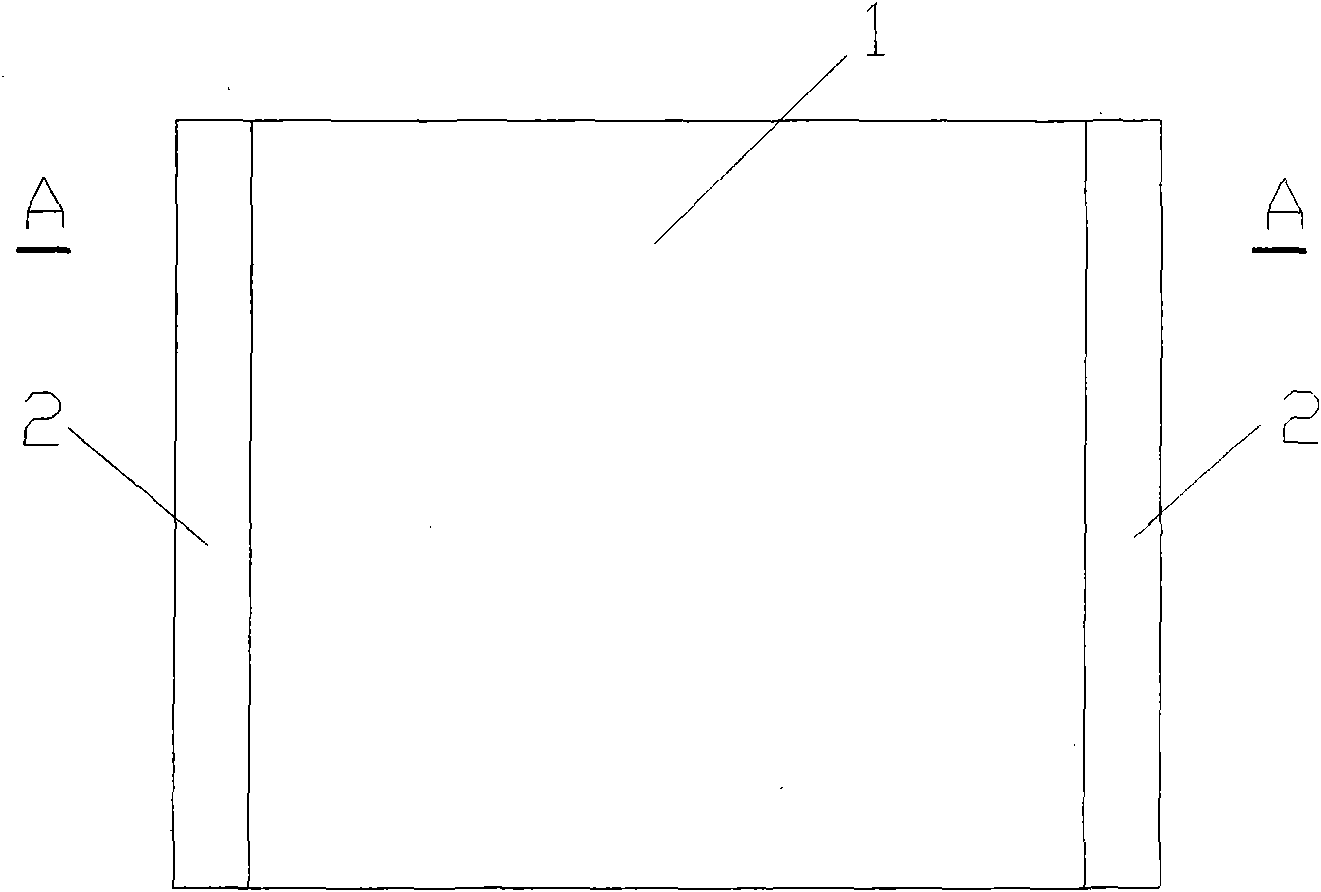

[0024] Attached below Figure 1-4 An embodiment of the present invention will be described.

[0025] First of all, according to the force of the shear wall and the required functional requirements of thermal insulation, energy saving and sound insulation, the size and position of each component inside the shear wall are determined.

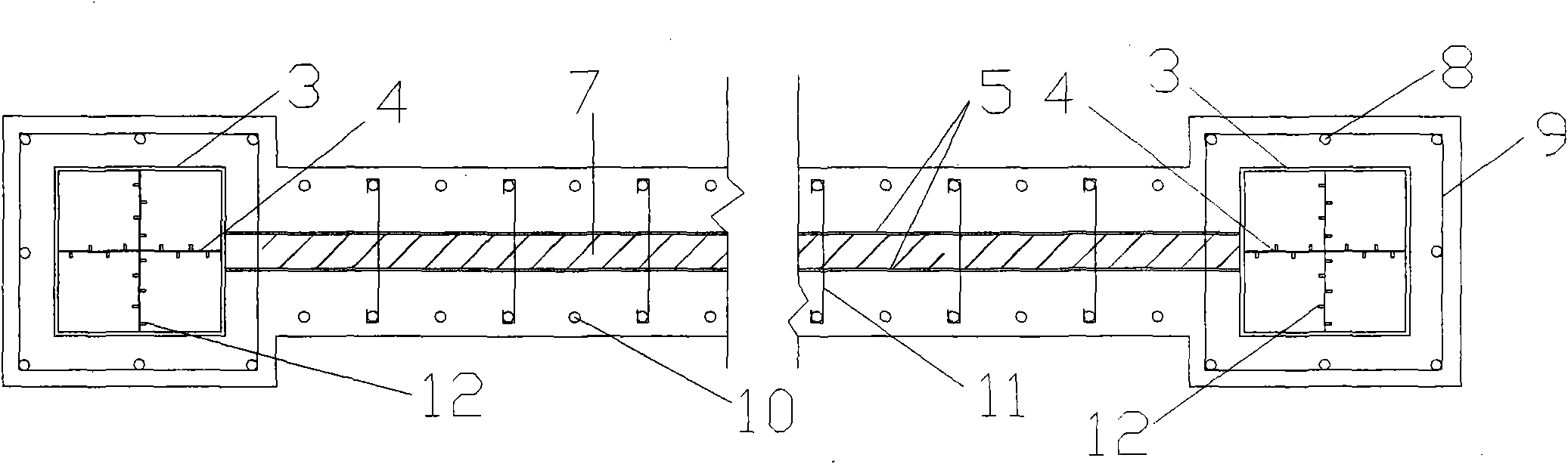

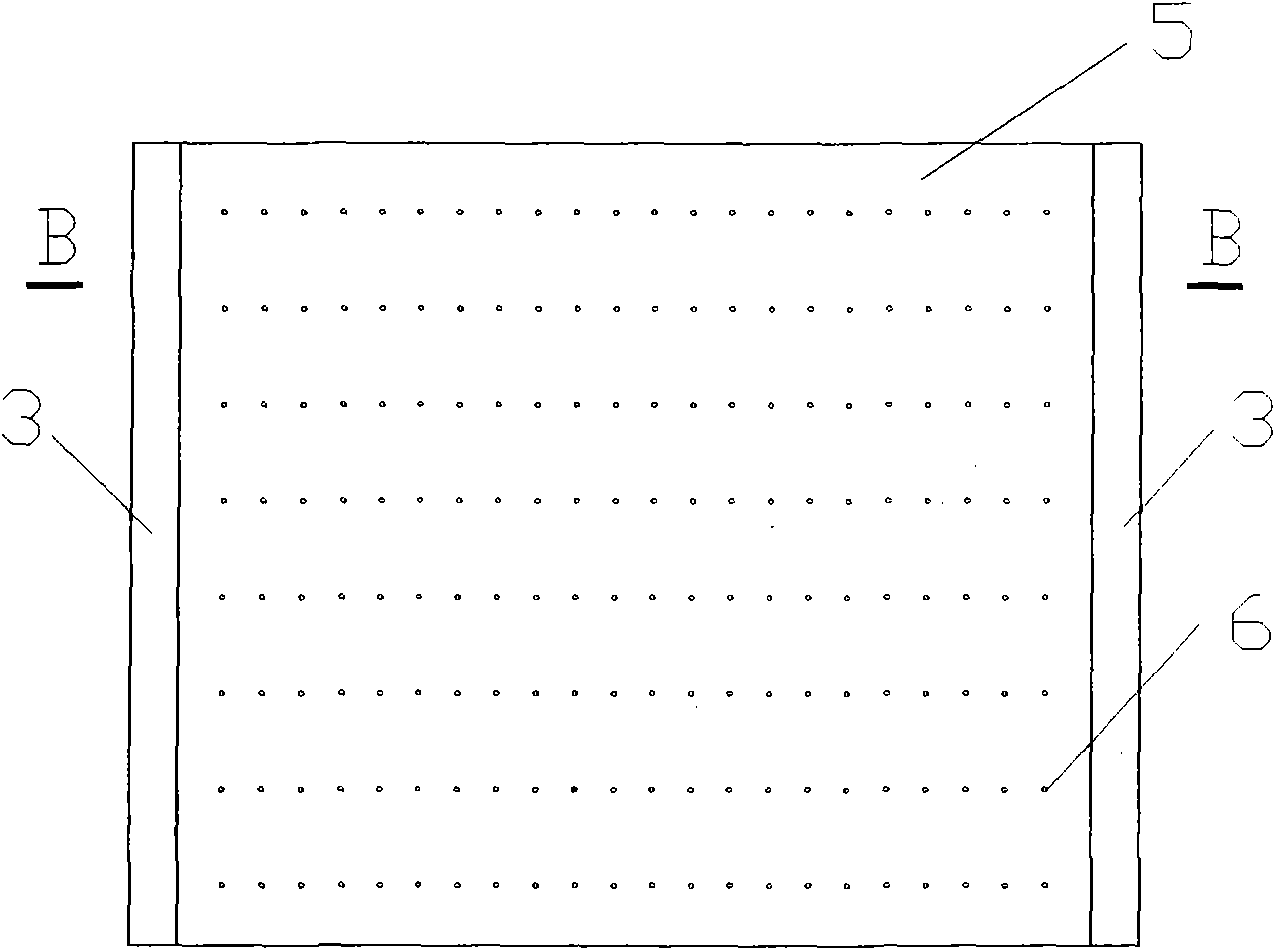

[0026] According to the needs, set the steel pipe concrete composite column 2 at the appropriate position on both sides of the shear wall body 1. When pouring the concrete in the steel pipe 3, use the cross partition 4 to divide the cross section of the rectangular concrete column in the steel pipe into 4 independent equal-section units column. The cross partition adopts a thin iron sheet with a thickness of 0.5 mm, and many screws are spot-welded on the thin iron sheet as friction keys 12 .

[0027] Next, welding double-layer steel plates 5 are arranged between the steel pipes, and the required thermal insulation and sound insulation material 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com