Device for measuring multi-passage heat conductivity

A measuring device and multi-channel technology, applied in measuring devices, measuring heat, using electrical devices, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

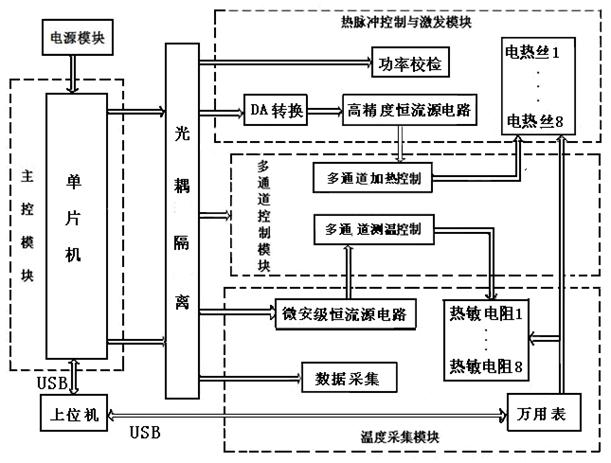

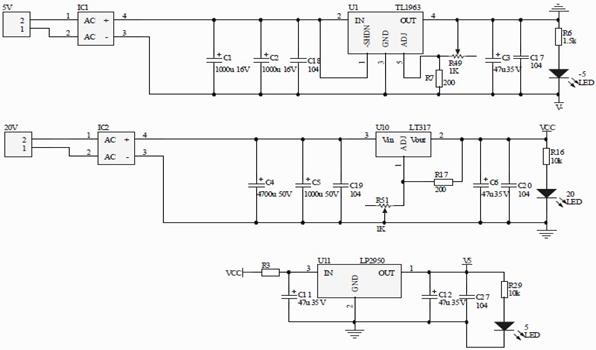

[0034]Embodiment 1: A kind of multi-channel thermal conductivity measuring device of the present invention, the structure is as follows figure 1 , including power supply module, upper computer, main control module, optocoupler isolation module, thermal pulse control and excitation module, multi-channel control module and temperature acquisition module;

[0035] The upper computer is respectively connected to the single chip microcomputer of the main control module and the six and a half multimeter in the temperature acquisition module through USB;

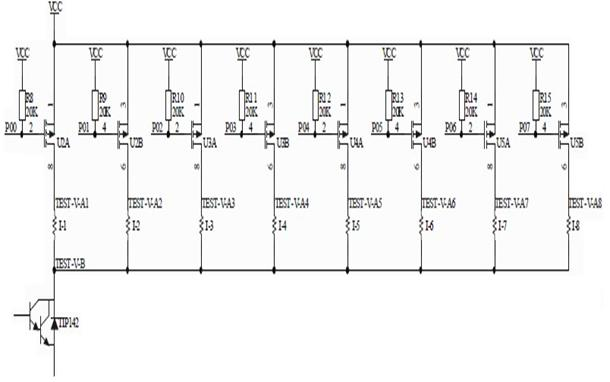

[0036] After each I / O of the microcontroller in the main control module is isolated by an optocoupler, they are respectively connected to the thermal pulse control and excitation module, the multi-channel control module and the temperature acquisition module;

[0037] The thermal pulse control and excitation module includes a power calibration module, a DA conversion module, a high-precision constant current source circuit and a he...

Embodiment 2

[0054] Embodiment 2: The multi-channel thermal conductivity measuring device of the present invention of application embodiment 1 is used to measure the thermal conductivity of rock, and the measurement work process is:

[0055] ① First insert the probe into the rock medium;

[0056] ② Turn on the host computer and single-chip microcomputer, run the measurement software, and the temperature acquisition module in the device first judges whether the ambient temperature is stable;

[0057] ③ After meeting the temperature balance conditions, first set the corresponding heating power on the host computer according to the rock medium;

[0058] ④The single-chip microcomputer realizes the gating of the channel through the switching action of the field effect tube, and the device controls the high-precision constant current source to generate current through the high-speed single-chip microcomputer, and the current flows through the gated channel through the heating wire to generate he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com