Gelatin embedding process of orthopedic implanting material and equipment thereof

An implant material, gelatin technology, applied in medical science, prosthesis, coating, etc., can solve problems such as uneven antibiotic content, denaturation, and irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

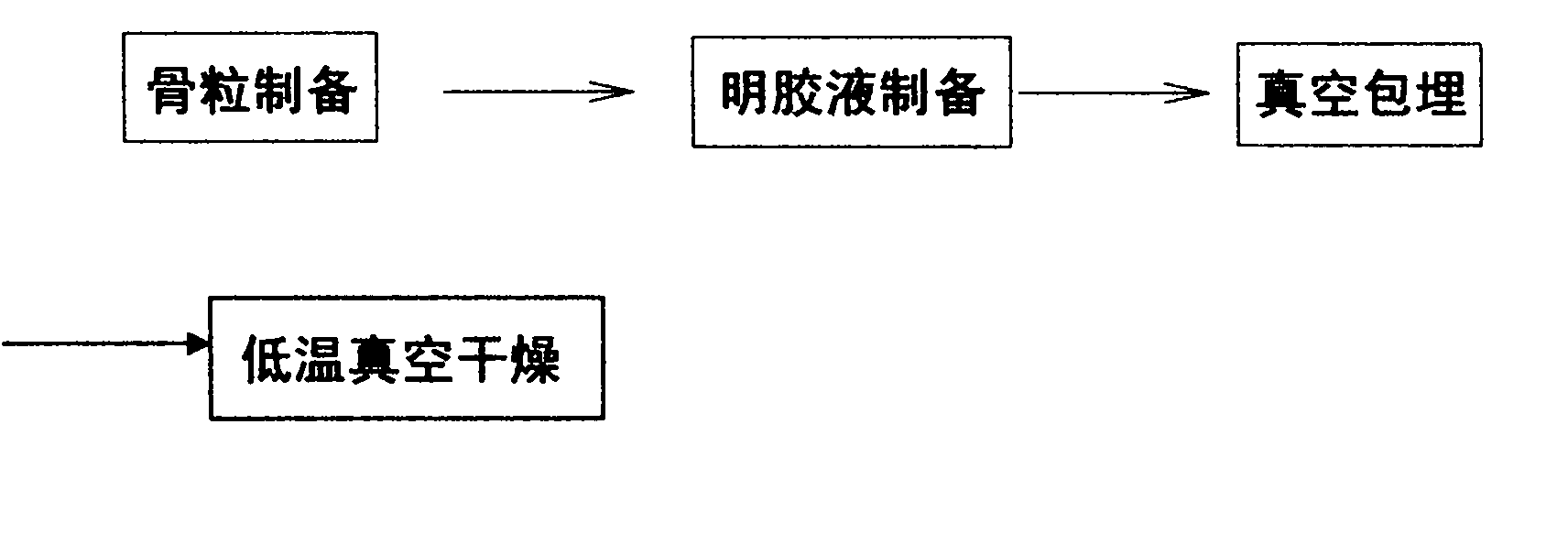

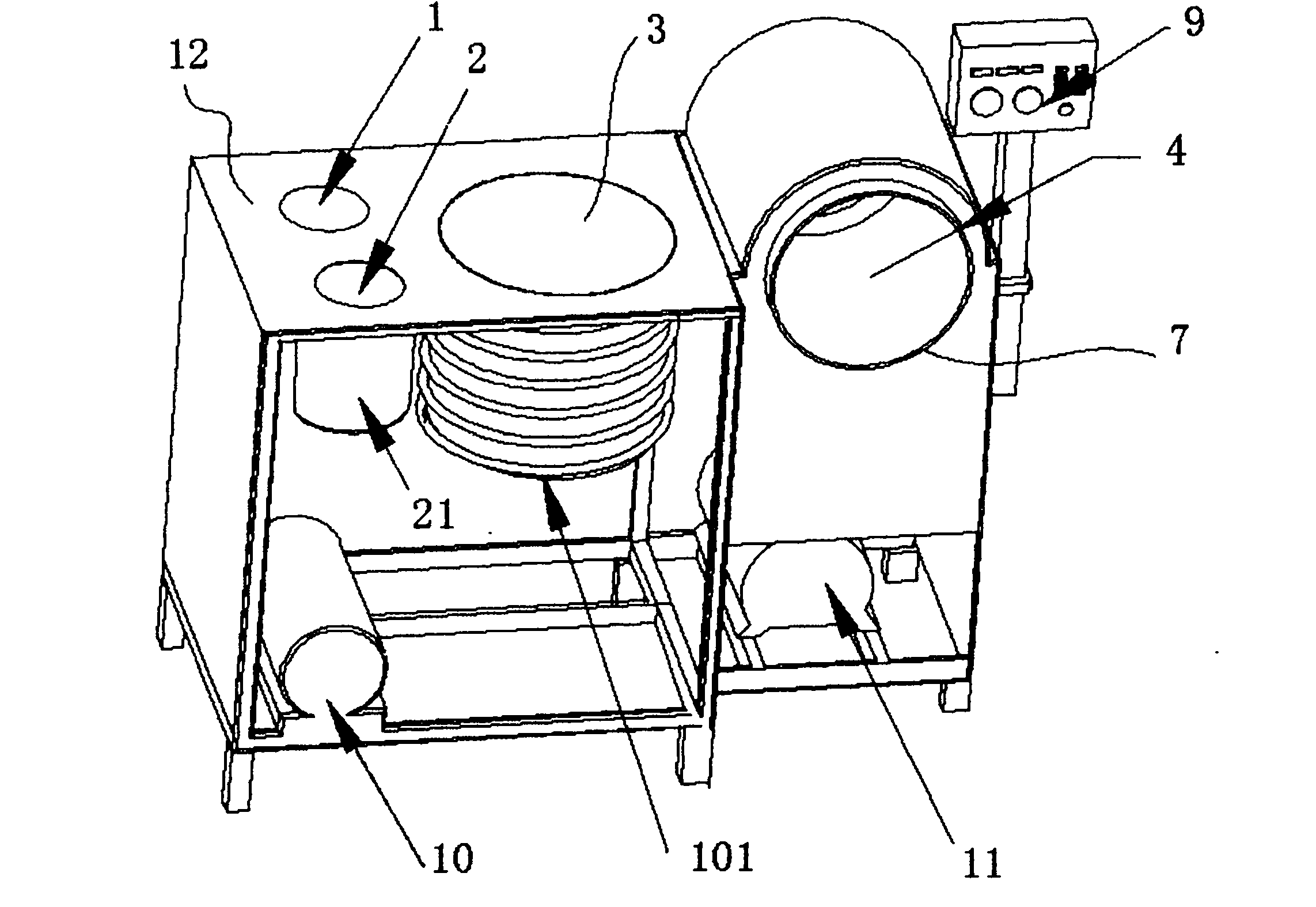

[0037] A gelatin embedding process for orthopedic implant materials, such as figure 1 shown. (the equipment used in the present invention is shown in Table 1, as figure 2 shown)

[0038] Technology of the present invention comprises the following steps:

[0039] (1) Preparation of bone particles:

[0040] Cut the fresh bovine bone into bone pellets with a diameter of 5mm*5mm, wash, degrease, decalcify and dry for later use; (the specific operation is the prior art, so it is omitted); put the bone pellets into the bone pellet preheating tank 1 for preheating to 50°C, stand-by;

[0041] A rubber-impregnated net basket is arranged in the bone grain preheating tank 1, and a rubber-impregnated net basket is also arranged in the vacuum gelatin preparation tank 2, and the rubber-impregnated net basket is not shown in the drawings.

[0042] (2) Preparation process of gelatin solution:

[0043] Weigh 750g of sterile gelatin with an electronic weighing scale according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com