Method for manufacturing cold-drawing gas cylinder tube for medical oxygen cylinder

A manufacturing method and technology of gas cylinder tubes, applied to the manufacture of cold-drawn gas cylinder tubes for medical oxygen cylinders, in the field of medical oxygen cylinders, can solve the problem of the manufacturing method of cold-drawn gas cylinder tubes for medical oxygen cylinders and the surface quality of gas cylinders that have not yet been found Inadequate, poor safety and reliability, etc., to achieve the effect of product safety, reliability, light weight and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific examples, and the following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

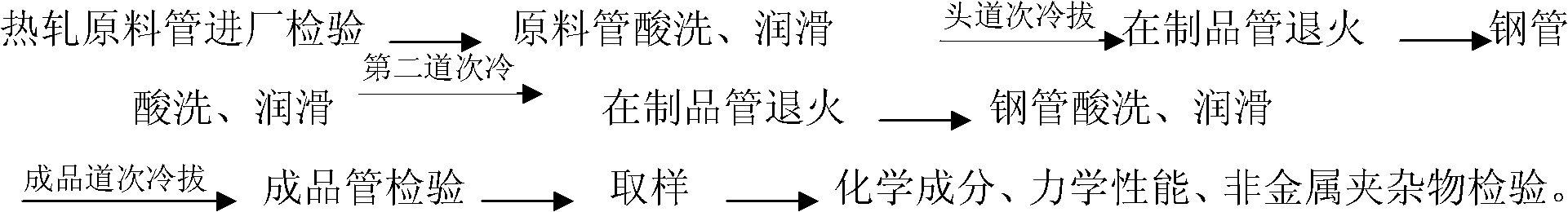

[0028] A method for manufacturing cold-drawn gas cylinder tubes for medical oxygen cylinders, the production process is as follows:

[0029]

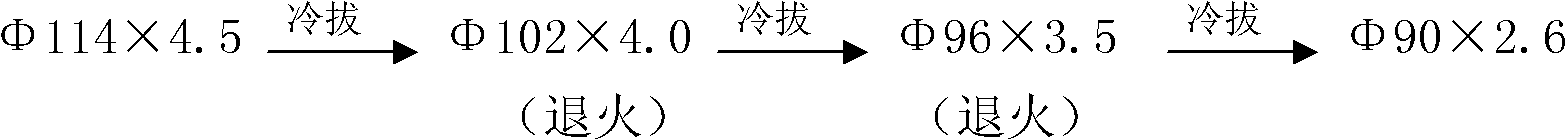

[0030] The cold drawing deformation process route of the present invention is:

[0031]

[0032] According to the design of the cold drawing deformation process, the geometric dimensions of the inner and outer molds of each deformation pass are selected, and the geometric dimensions and surface quality of the in-process and finished pipes of each pass are well controlled.

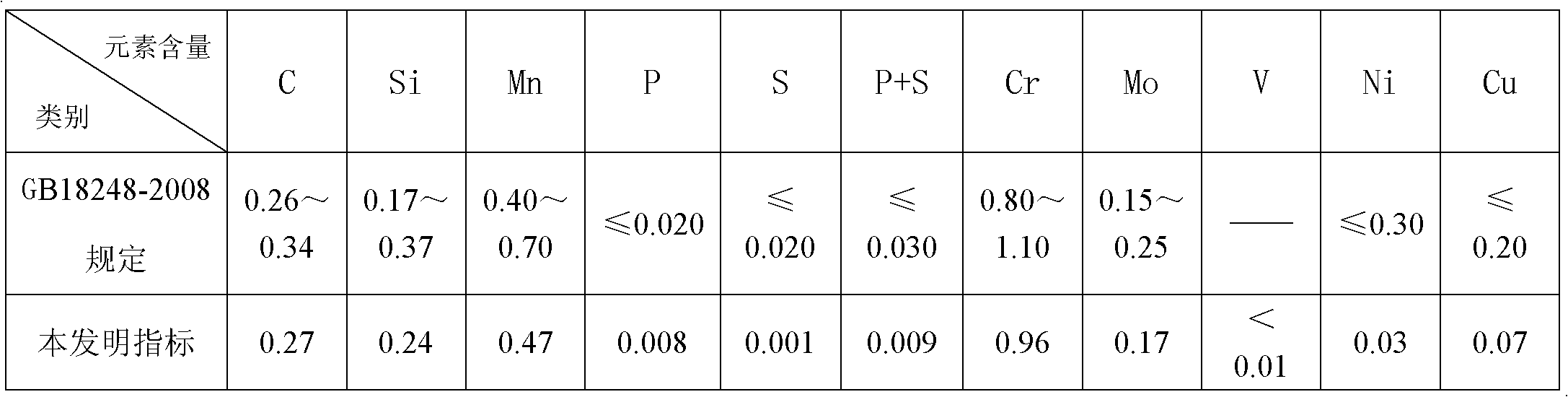

[0033] Concrete process steps are:

[0034] (1) Incoming inspection of hot-rolled raw material pipes

[0035] Select the raw material tube specification according to the finished product specification, determine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com