Micro-electrode array based on electrostatic induction load dispatching and online horizontal electrospark machining method of array hole

An array electrode, electrostatic induction technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable discharge state, affecting the machining accuracy and machining quality of array holes, and difficult to guarantee position accuracy, and achieve optimization. Effects of machining parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

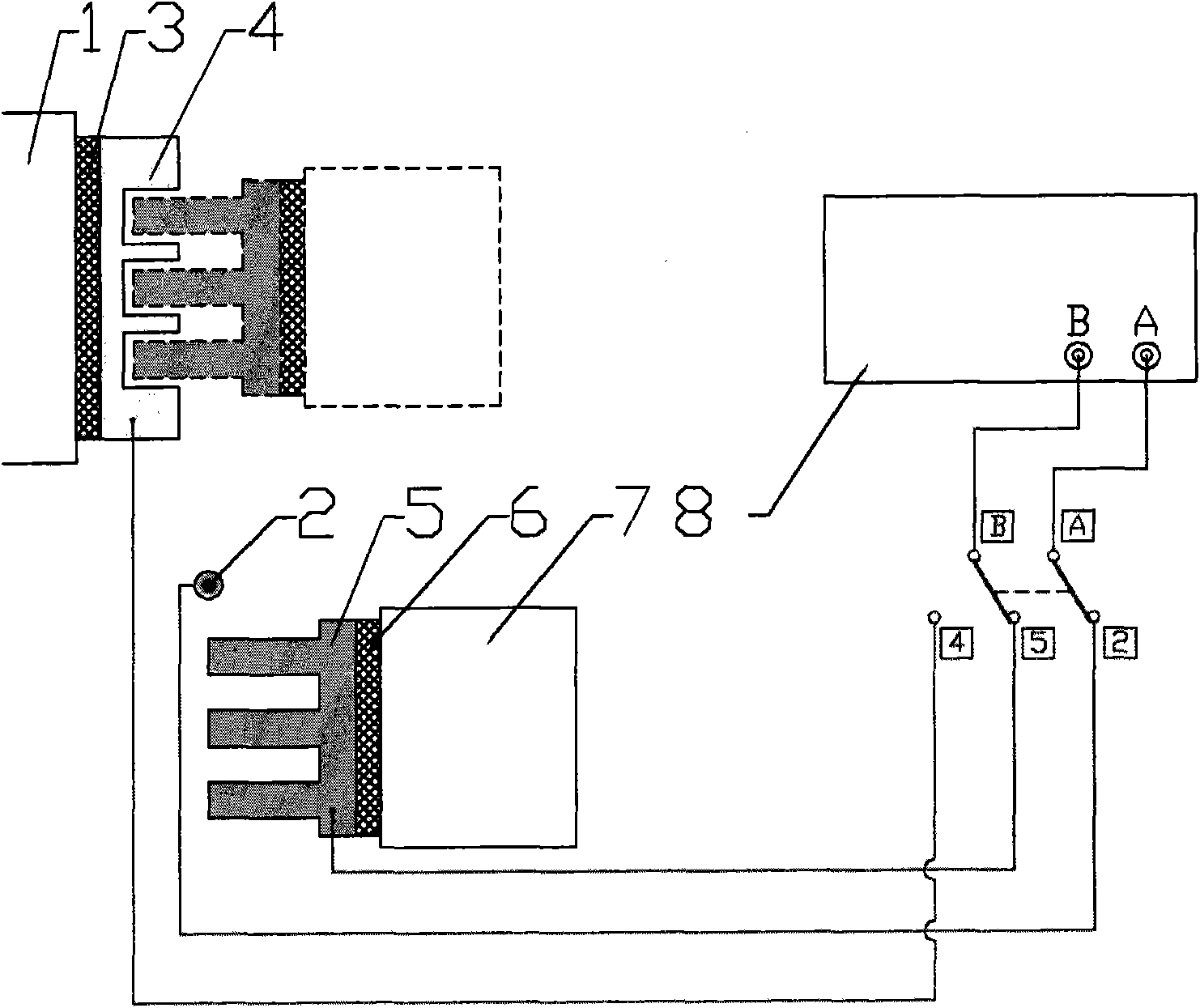

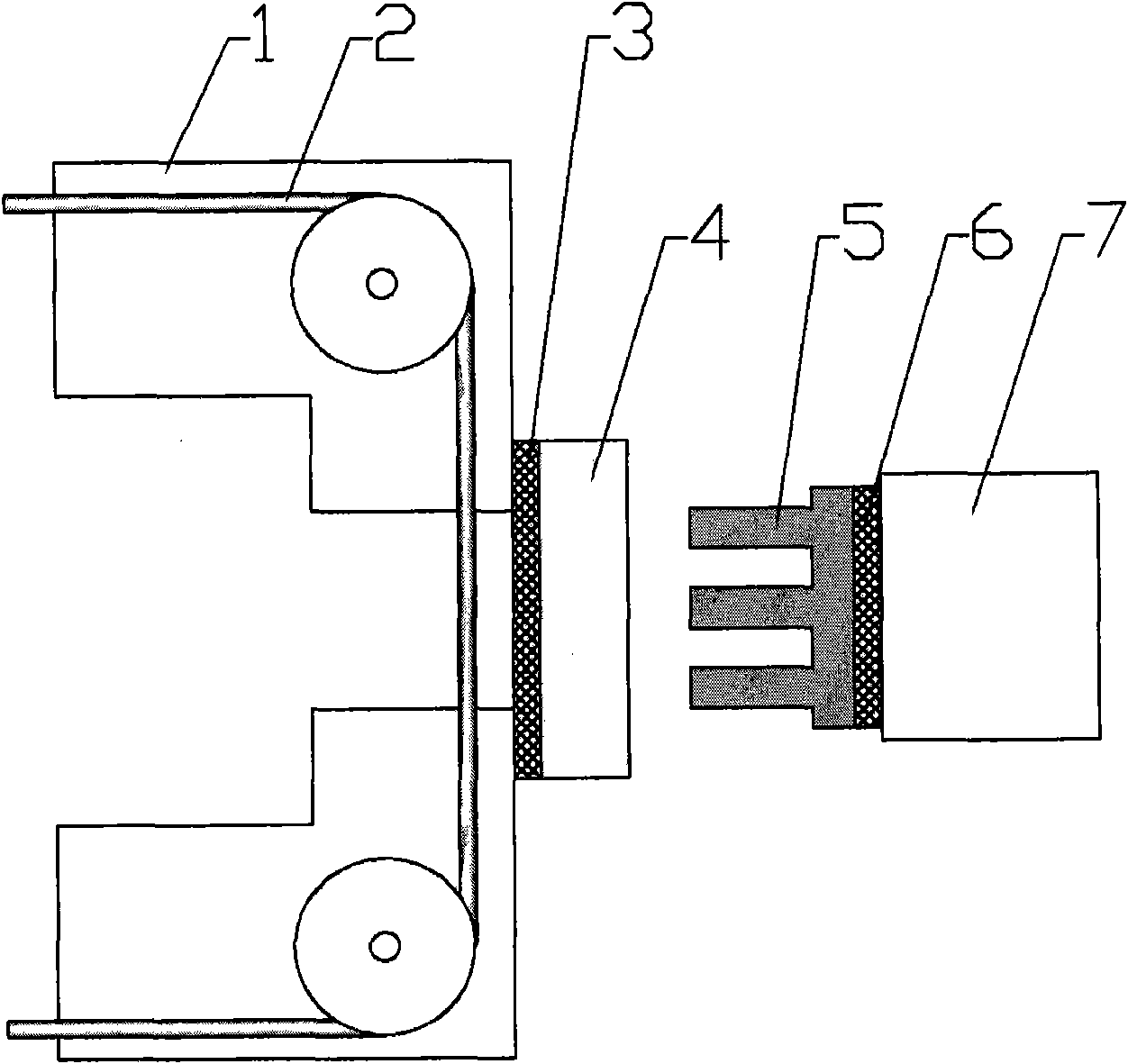

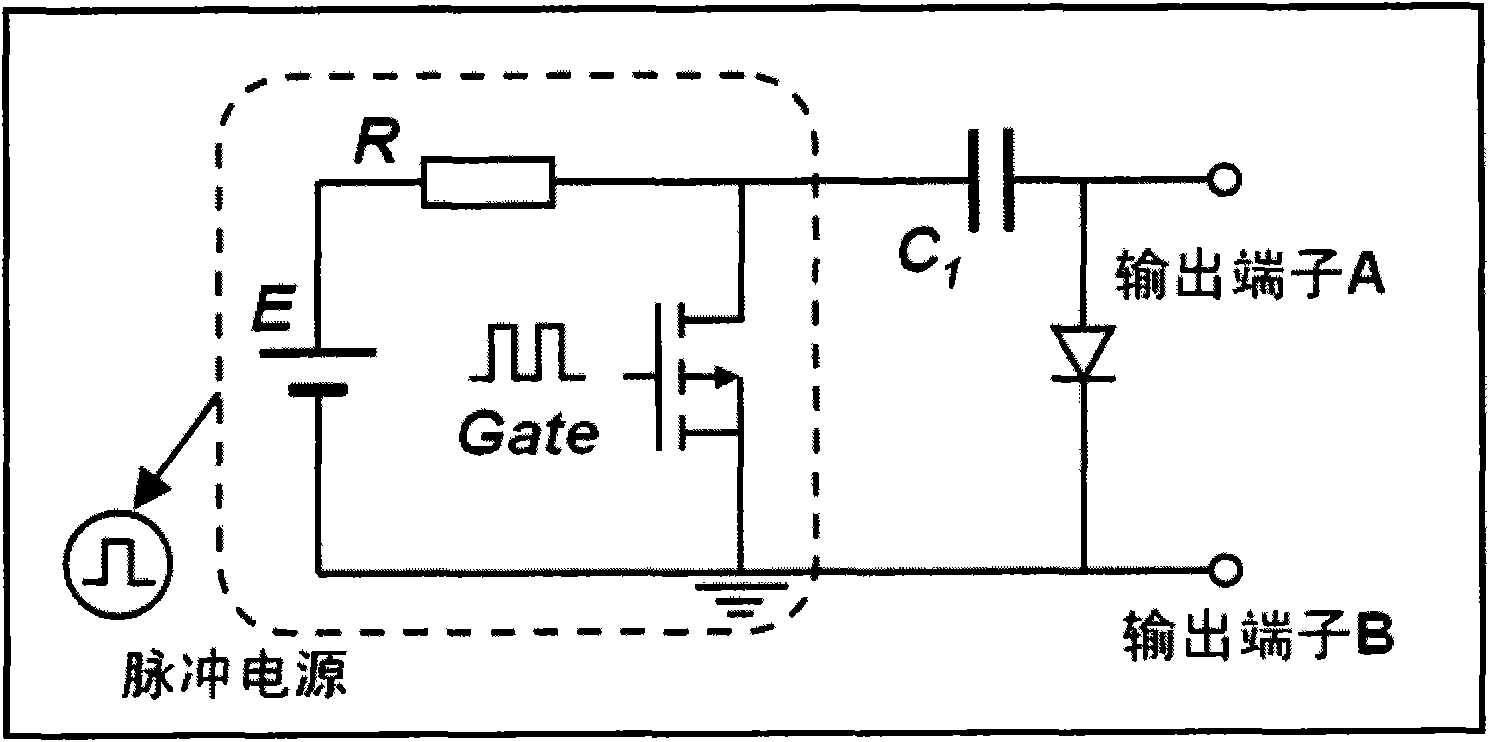

[0017] Such as figure 1 and 2 As shown, the processing method of micro-array electrodes and array holes is completed on a micro-wire electric discharge machine tool. In the figure, the array hole workpiece 4 is vertically clamped on the wire frame 1 of the micro-wire electric discharge machine tool by the special insulating fixture 3, and the array electrode square bar 5 is clamped on the workbench 7 of the machine tool by the special insulating fixture 6. The machine tool table 7 can drive the array electrode square bar 5 to move between the position of the electrode wire 2 and the array hole workpiece 4, and the static induction unipolar power supply 8 can selectively control the electrode wire 2 and the array electrode square bar respectively. The material 5 or the array electrode square rod 5 and the array hole workpiece 4 are powered.

[0018] The specific implementation of the present invention includes two parts: the preparation of the micro-array electrodes and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com