Method for preparing transparent organic hydrophobic coating on surface of aluminum plate

A technology of hydrophobic coating and aluminum plate, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problem of poor adhesion, high hydrophobicity and service life, complicated preparation process and equipment And other problems, to achieve good hydrophobicity, self-cleaning effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

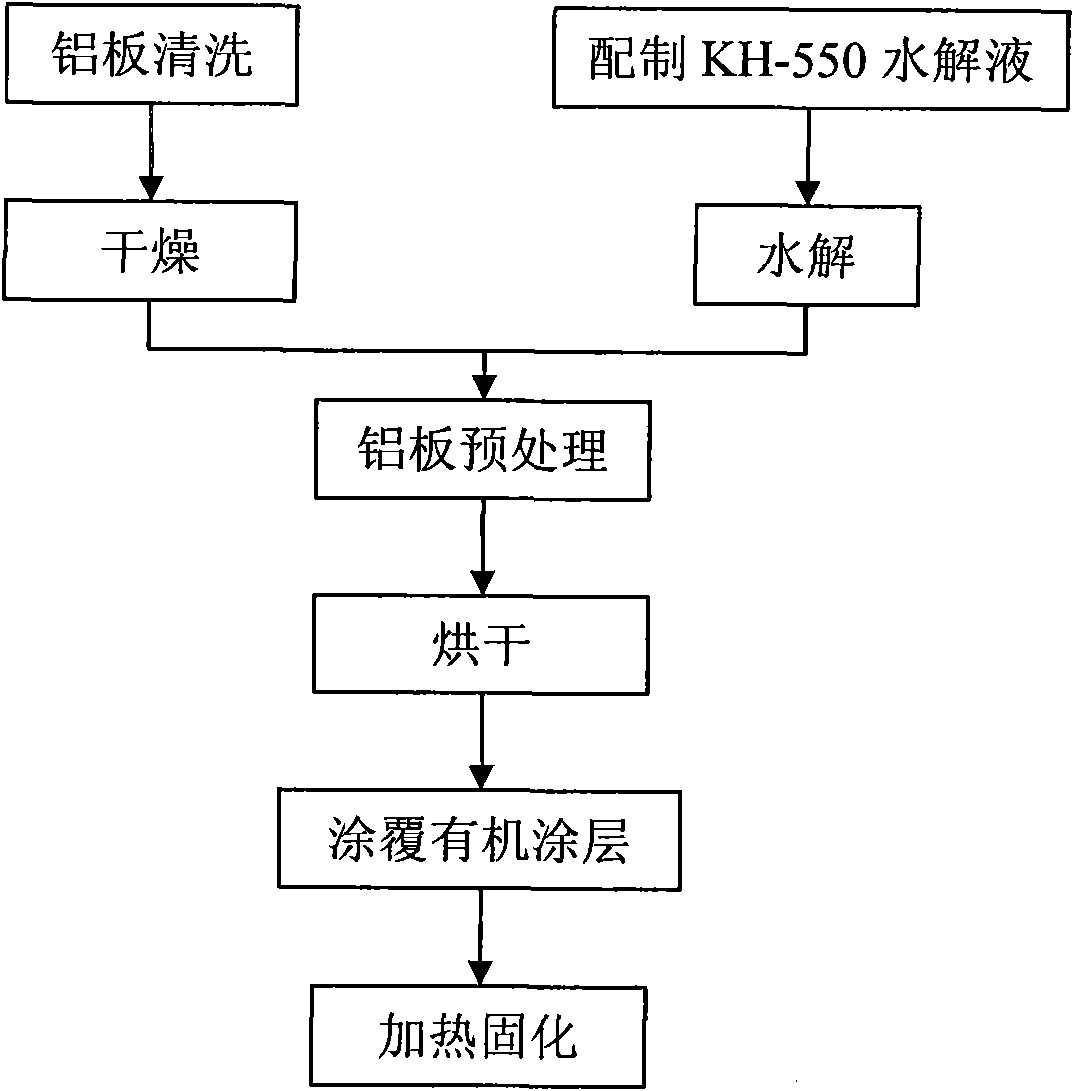

[0017] A kind of preparation method of transparent organic hydrophobic coating on the surface of aluminum plate, selects the 1060 aluminum plate of common rolling for use, according to figure 2 Steps shown:

[0018] 1) First, use ethanol to clean the surface of the aluminum plate to remove the remaining oil on the surface and other dirt that will affect the reaction with silane in the next step, then rinse with water and dry naturally;

[0019] 2) A hydrolysis solution was prepared by γ-aminopropyltriethoxysilane, distilled water and absolute ethanol (analytical grade), and the volume ratio of the three was 2:1:40. The prepared hydrolyzed solution is kept at 20° C. for 100 min, during which time the hydrolyzed solution can be stirred.

[0020] 3) Treat the surface of the aluminum plate with the hydrolysis solution by means of shower coating, and keep the process for 2 minutes, and then place the aluminum plate at 150° C. for 30 minutes to dry.

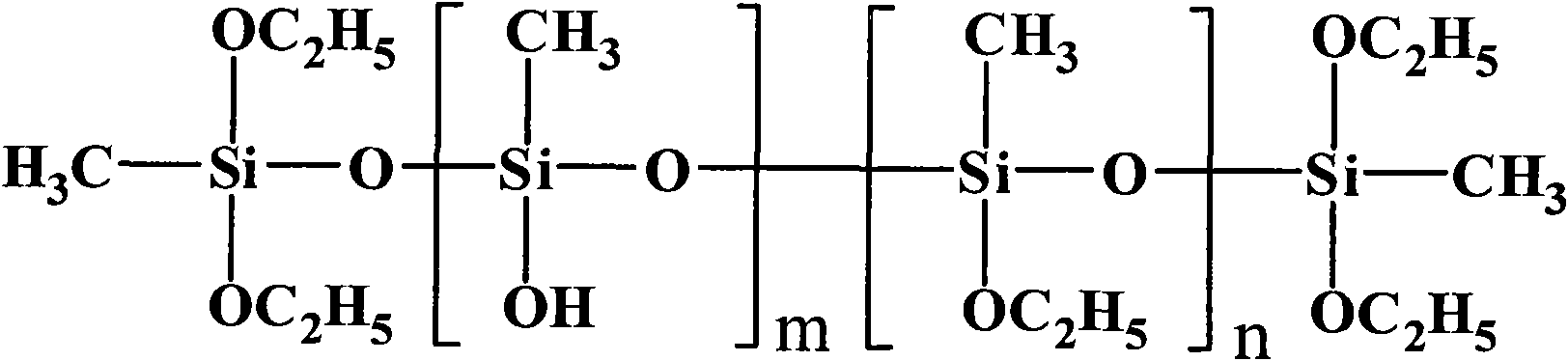

[0021] 4) Coating organic si...

Embodiment 2

[0023] A kind of preparation method of transparent organic hydrophobic coating on the surface of aluminum plate, select AA1070 aluminum plate for use, according to figure 2 Steps shown:

[0024] 1) First, use ethanol to clean the surface of the aluminum plate to remove the remaining oil on the surface and other dirt that will affect the reaction with silane in the next step, then rinse with water and dry naturally;

[0025] 2) A hydrolysis solution was prepared by γ-aminopropyltriethoxysilane, distilled water and absolute ethanol (analytical grade), and the volume ratio of the three was 4:1:40. The prepared hydrolyzed solution is kept at 30° C. for 70 min, during which time the hydrolyzed solution can be stirred.

[0026] 3) Treat the surface of the aluminum plate with the hydrolysis solution, or immerse the aluminum plate in the hydrolysis solution to make the hydrolysis solution react with the surface of the aluminum plate. The process is kept for 1 min, and then the alumi...

Embodiment 3

[0029] The organic coating prepared by the method of the present invention is mainly subjected to cross-sectional SEM test analysis and performance tests such as hydrophobicity, adhesion, light transmittance, corrosion resistance and weather resistance.

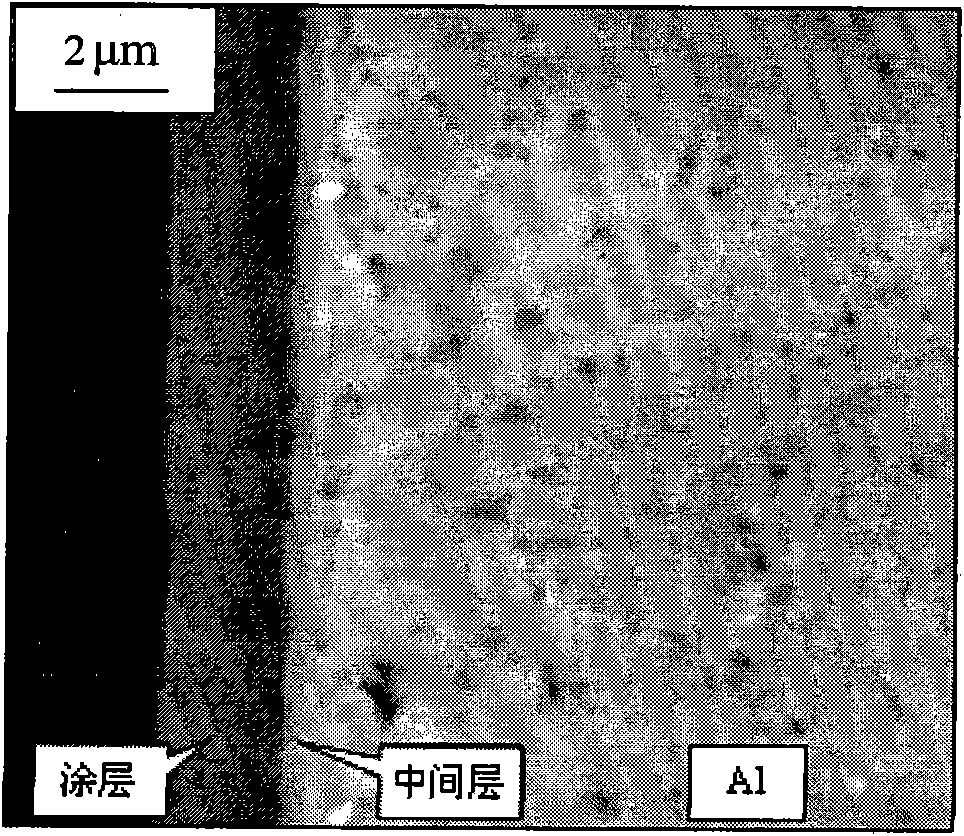

[0030] 1) Cut the aluminum plate with organic coating into 0.5cm×1cm sample, clamp it with copper sheet, and grind the metallographic sample. After Cr 2 o 3 After polishing, carry out gold-spraying treatment on the surface of metallographic sample, as embodiment 1, then place under JXA-840 type scanning electron microscope, observe cross-section appearance, and measure coating thickness, the result is as follows image 3 shown.

[0031] 2) Select an aluminum plate sample with a clean surface with an organic coating, and use a syringe to continuously add distilled water to the surface until the height of the water drop does not increase. During this process, keep the needle of the syringe inside the water drop. According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com