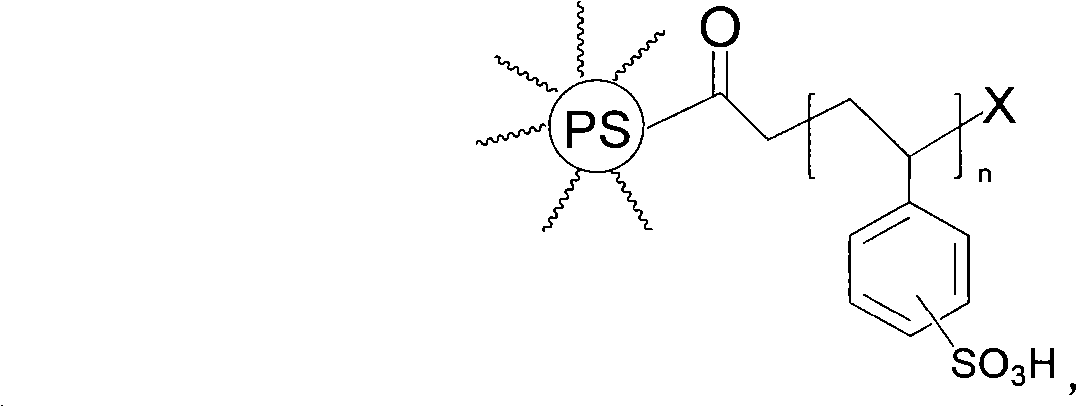

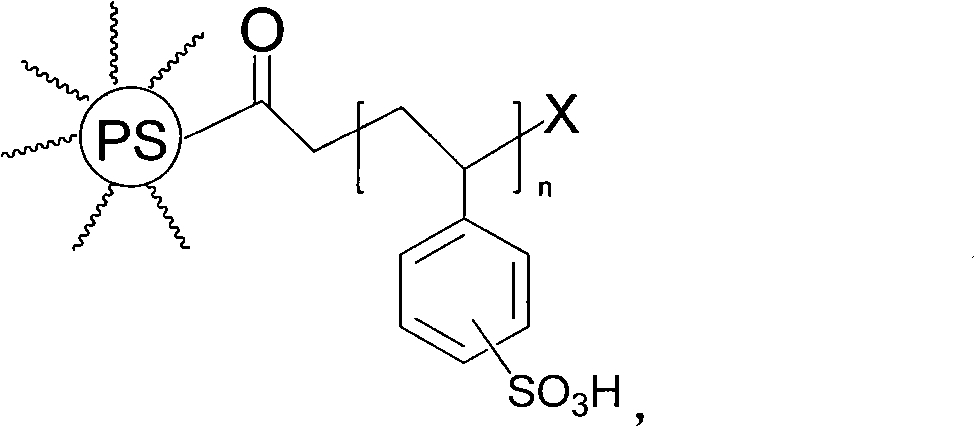

Polystyrene star-like sulfonic resin

A polystyrene and sulfonic acid resin technology, applied in the field of functional polymers, can solve problems such as resin breakage, and achieve the effect of reducing negative effects and increasing contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 0.5g PS-acyl-Cl resin (crosslinking degree: 7% divinylbenzene, particle size: 200μm) into a single-necked flask, add dimethyl sulfoxide, swell for 5h, add 8mL styrene, 0.05g CuCl, 0.08 g 2,2'-Bipyridine, vacuumize and nitrogen-fill alternately for 5 times, and react with magnetic stirring at 110°C for 24h under nitrogen atmosphere. A styrene-grafted PS-g-LPS resin was obtained.

[0027] After 0.5 g of the above resin was swollen with cyclohexane for 7 hours, 1.7 mL of 98% sulfuric acid and 1.45 mL of acetic anhydride were added, and the reaction was carried out at 90°C for 5 hours to obtain a polystyrene star sulfonic acid resin with a loading capacity of 4.9 mmol / g. .

Embodiment 2

[0029] Add 0.5g PS-acyl-Cl resin (crosslinking degree: 7% divinylbenzene, particle size: 600μm) into a single-necked flask, add N,N'-dimethylformamide, swell for 10h, add 5mL styrene, 0.15g CuCl, 0.17g pentamethyldiethylenetriamine, evacuated and nitrogen filled alternately for 5 times, and reacted with magnetic stirring at 105°C for 4h under nitrogen atmosphere. A styrene-grafted PS-g-LPS resin was obtained.

[0030] After 0.5 g of the above resin was swollen with pyridine for 2 h, 0.90 mL of concentrated sulfuric acid was added, and the reaction was carried out at 75° C. for 3 h to obtain a polystyrene star sulfonic acid resin with a loading capacity of 2.0 mmol / g.

Embodiment 3

[0032] Add 0.5g PS-acyl-Cl resin (crosslinking degree: 7% divinylbenzene, particle size: 50μm) into a single-necked flask, add toluene, swell for 1h, add 10mL styrene, 0.2g CuCl, 0.22g tetramethyl Ethylenediamine was vacuumized and nitrogen filled alternately 5 times, and reacted with magnetic stirring at 100° C. for 15 h under nitrogen atmosphere. A styrene-grafted PS-g-LPS resin was obtained.

[0033] After 0.5 g of the above resin was swollen with 1,2-dichloroethane for 3 hours, 1.0 mL of oleum was added, and the reaction was carried out at 80°C for 8 hours to obtain polystyrene star sulfonic acid with a loading capacity of 3.6 mmol / g. resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com