Shaft lever part for engineering machinery and manufacturing method thereof

A technology of construction machinery and manufacturing methods, applied in the direction of mechanical equipment, shafts, bearings, shafts, etc., can solve the problems of low cost performance and defects of shaft parts, and achieve the effect of small deformation and strong abrasive wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

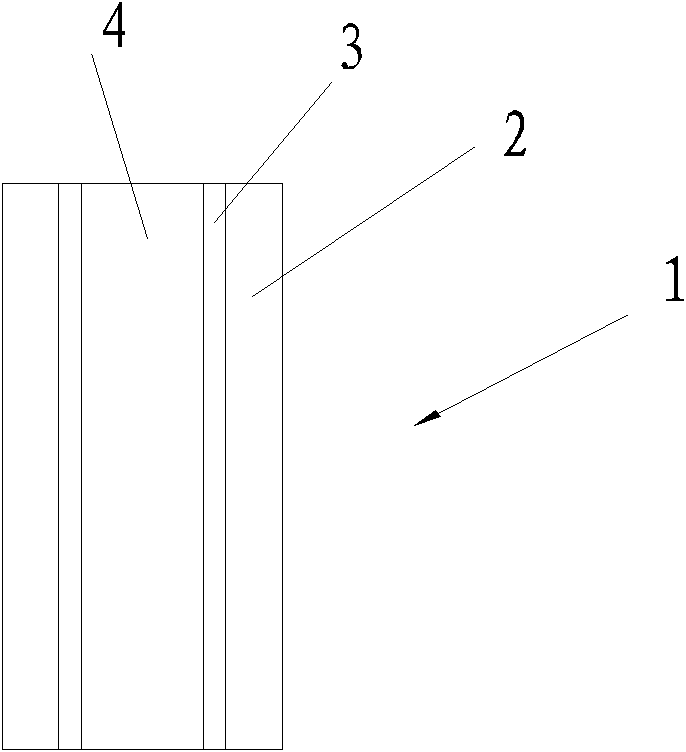

Image

Examples

Embodiment 1

[0028] Embodiment 1, a manufacturing method of shaft rod parts for construction machinery:

[0029] 1. Cutting;

[0030] 2. Quenching and tempering heat treatment process, heating the workpiece to 830°C, calculating the holding time according to the diameter of the workpiece, the holding time is 1min / mm, and quenching with 8%-12% by mass of brine. When the shaking of the workpiece in the water stops, the water can be cooled by air. Then temper at 560°C for 3 hours, and air cool to room temperature;

[0031] 3. Rough turning, turned into a shaft with a radius of 17.5mm on a lathe;

[0032] 4. Surface induction hardening process, power: 70KW, workpiece moving speed: 70mm / min, water pressure: 0.1MPa, current: 300A, voltage: 400V, frequency: 1000Hz;

[0033] 5. Stress-relieving and tempering, heating to 180°C, and holding for 3 hours.

[0034] After the hardness test, the surface hardness is 58HRC, and the depth of the quenching hardened layer is D S 5.25mm, the depth D of th...

Embodiment 2

[0035] Embodiment 2. A manufacturing method of shaft rod parts for engineering machinery:

[0036] 1. Cutting;

[0037] 2. Quenching and tempering heat treatment process, heating the workpiece to 840°C, calculating the holding time according to the diameter of the workpiece, the holding time is 1min / mm, and quenching with 8%-12% by mass of brine. When the shaking of the workpiece in the water stops, the water can be cooled by air. Then temper at 590°C for 3 hours, and air cool to room temperature;

[0038] 3. Rough turning, turned into a shaft with a radius of 50mm on a lathe;

[0039] 4. Surface induction hardening process, power: 110KW, workpiece moving speed: 200mm / min, water pressure: 0.15MPa, current: 360A, voltage: 460V, frequency: 1800Hz;

[0040] 5. Stress-relief tempering, heating to 200°C, and holding for 3 hours.

[0041] After the hardness test, the surface hardness is 56HRC, and the depth of the quenching hardened layer is D S 15mm, the depth D of the quench ...

Embodiment 3

[0042] Embodiment 3, a kind of manufacturing method of shaft rod type parts for engineering machinery:

[0043] 1. Cutting;

[0044] 2. Quenching and tempering heat treatment process, heating the workpiece to 860°C, calculating the holding time according to the diameter of the workpiece, the holding time is 1min / mm, and quenching with 8%-12% by mass of brine. When the shaking of the workpiece in the water stops, the water can be cooled by air. Then temper at 610°C for 3 hours, and air cool to room temperature;

[0045] 3. Rough turning, turned into a shaft with a radius of 70mm on a lathe;

[0046] 4. Surface induction hardening process, power: 160KW, workpiece moving speed: 400mm / min, water pressure: 0.20MPa, current: 430A, voltage: 480V, frequency: 2400Hz;

[0047] 5. Stress-relieving and tempering, heating to 230°C, and holding for 3 hours.

[0048] After the hardness test, the surface hardness is 55HRC, and the depth of the quenching hardened layer is D S 21.7mm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com