High-chromium cast iron type iron-based self-fluxing alloy powder

A technology of self-fluxing alloys and high-chromium cast iron, which is applied in metal processing equipment, welding media, welding/cutting media/materials, etc., and can solve large-size block shedding failures, cladding layer cracking failures, and cladding layer failures etc. to achieve good abrasive wear resistance, strong impact resistance, and high toughness of the wear-resistant layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. Surface strengthening of shearer picks

[0026] In this embodiment, the alloy powder is composed of the following mass ratio components:

[0027] Cr 26%, C 3.0%, B 2%, Si 1%, Mo 5%, Nb 3%, Ni 5%, Fe balance.

[0028] When in use, use the water atomization method to prepare the alloy powder of the above components, and screen the powder with a mesh size of 100-300. The alloy powder of the present invention is uniformly fused on the surface of the pick by adopting argon arc surfacing technology. The thickness of the cladding layer is 0.3~1mm, and the hardness is 61~64HRC. In the cladding layer of this example, the carbides are mainly M 7 C 3 , Carbide accounted for 36% of the weight of the cladding layer.

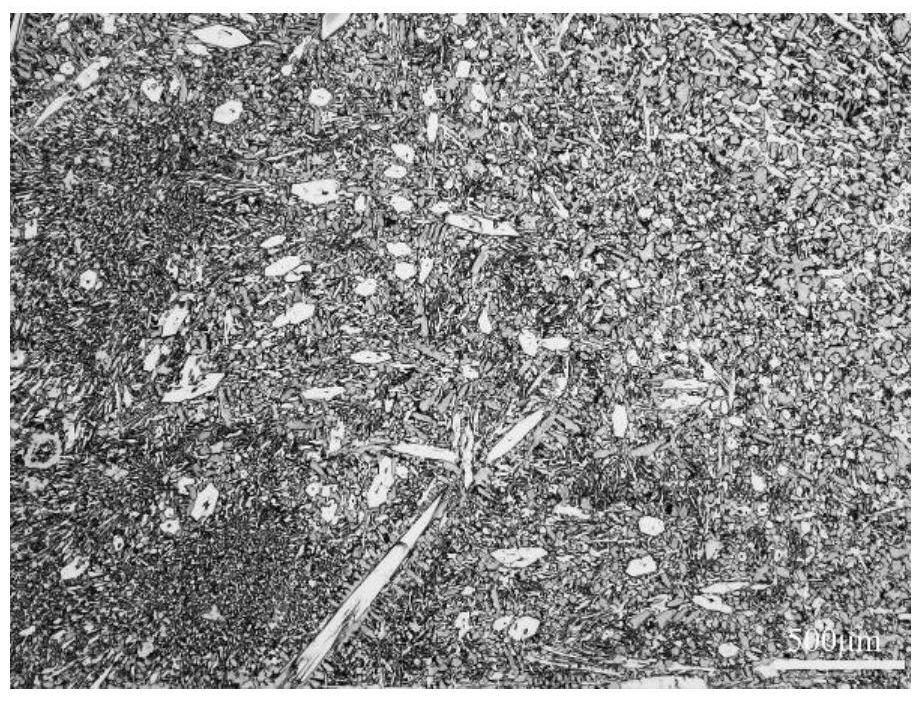

[0029] Such as Figure 1(a)-Figure 1(b) As shown, the structure of the wear-resistant layer is observed with a metallographic microscope. The wear-resistant layer is a hypereutectic structure, the hard phase carbides are isolated and uniformly distribu...

Embodiment 2

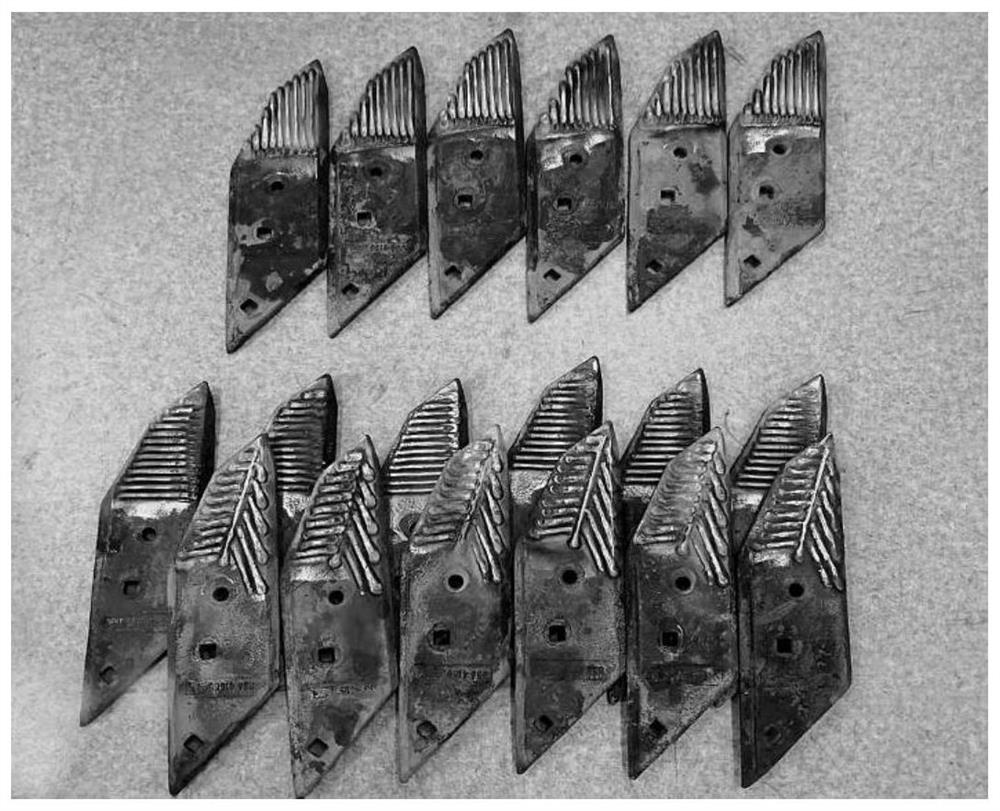

[0030] Example 2. Surface strengthening of plowshare shovel tip

[0031] In this embodiment, the alloy powder is composed of the following mass ratio components:

[0032] Cr 28%, C 3.1%, B 2%, Si 2%, Mo 3%, Nb 5%, Ni 5%, Fe balance.

[0033] When in use, use the water atomization method to prepare the alloy powder of the above components, and screen the powder with a mesh size of 100-200. Such as figure 2 As shown, the alloy powder of the present invention is evenly fused on the surface of the plowshare shovel tip by using plasma surfacing technology. The thickness of the cladding layer is 2.5~5mm, and the hardness is 63~65HRC. In the cladding layer of this example, the carbides are mainly M 7 C 3 , Carbide accounts for about 38% of the weight of the cladding layer.

[0034] The field assessment experiment was carried out in the sandy land in northern Xinjiang, and the results showed that: under the sandy soil conditions, the arable land area of the five plow plow load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com