Anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of not being resistant to sea water erosion, poor mechanical properties, etc., and achieve the effect of strong wear resistance, excellent mechanical properties, and resistance to sea water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of coating described in the present invention, comprises the following steps:

[0039] First mix polytitanium nanopolymer, petroleum resin, vinyl chloride resin, polyamine and dispersant, and then mix the obtained mixture with nano-silica, Mn-ZrC composite powder, modified bentonite, titanium nano-particles, colloid Graphite fine powder, fast extrusion carbon black N550 and organic solvent are mixed to obtain the coating.

Embodiment 1

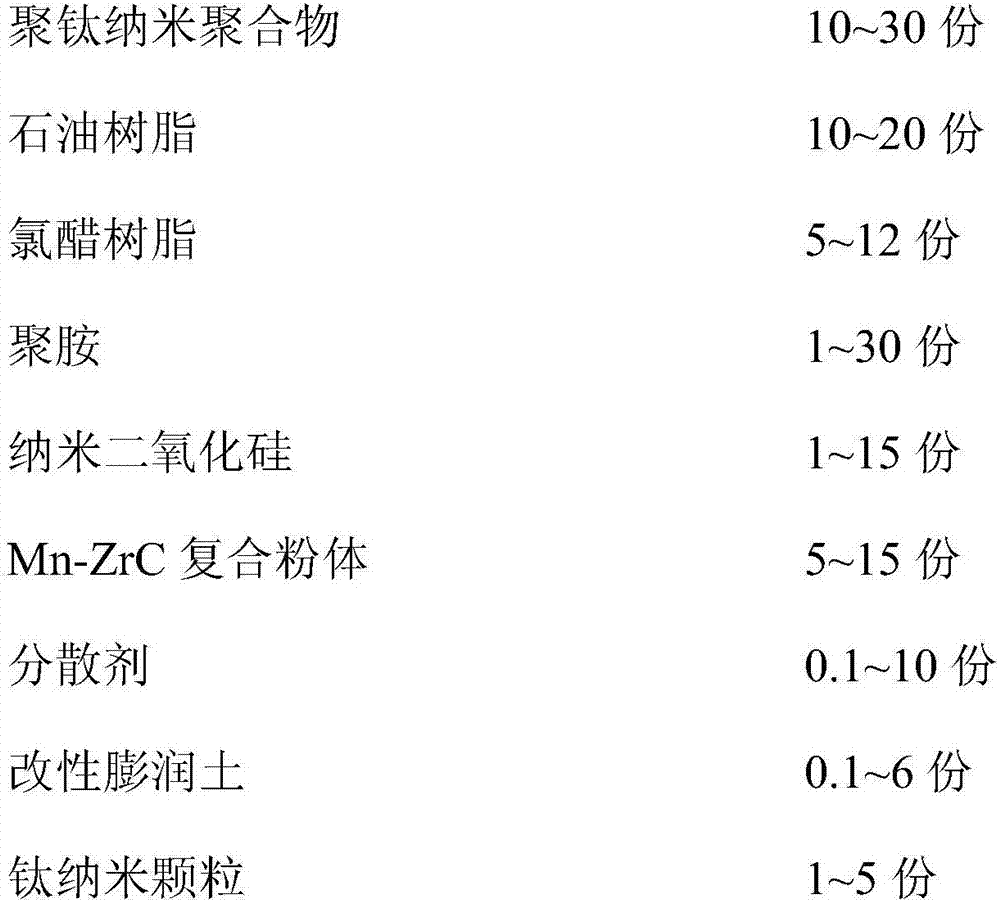

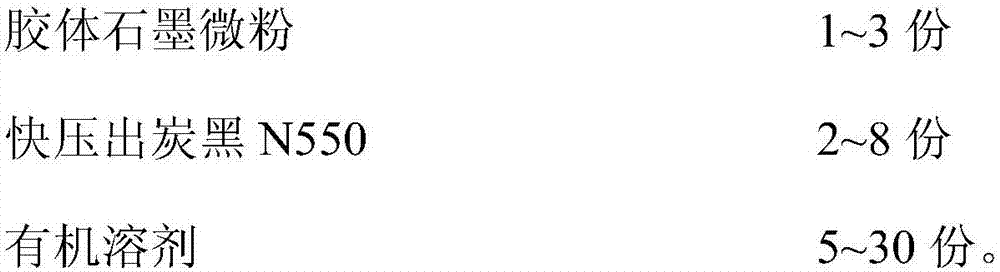

[0041] A kind of anticorrosion paint, it is made up of following raw material by weight:

[0042]

[0043] The preparation method of described coating is:

[0044] First mix polytitanium nanopolymer, petroleum resin, vinyl chloride resin, polyamine and dispersant, and then mix the obtained mixture with nano-silica, Mn-ZrC composite powder, modified bentonite, titanium nano-particles, colloid Graphite fine powder, fast extrusion carbon black N550 and organic solvent are mixed to obtain the coating.

Embodiment 2

[0046] A kind of anticorrosion paint, it is made up of following raw material by weight:

[0047]

[0048] The preparation method of described coating is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com