System of simulating characteristics of high-level waste geology treatment room

A technology for high-level radioactive waste and disposal room, which is used in radioactive purification, nuclear engineering and other directions to achieve the effects of high measurement accuracy, small deformation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

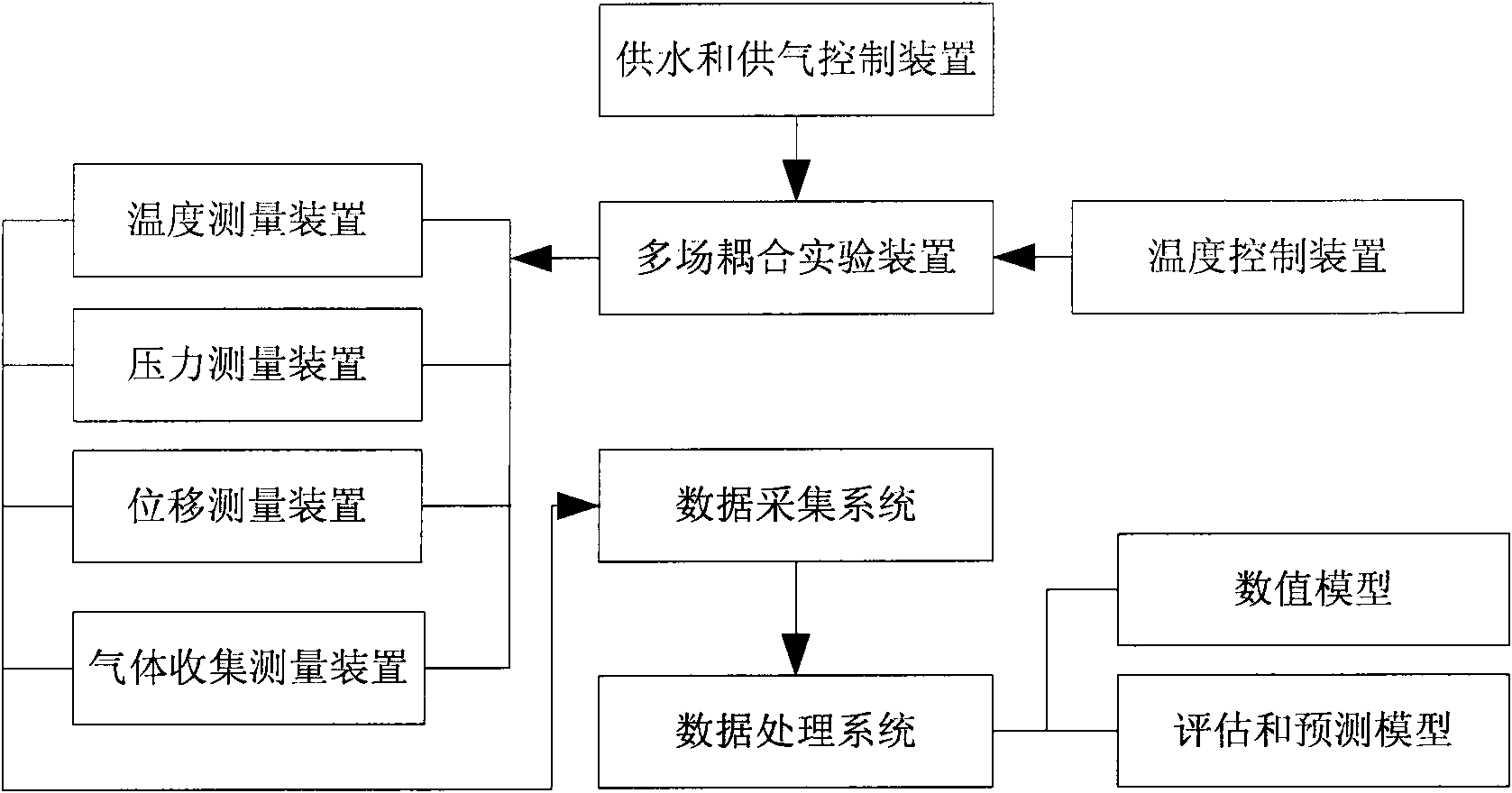

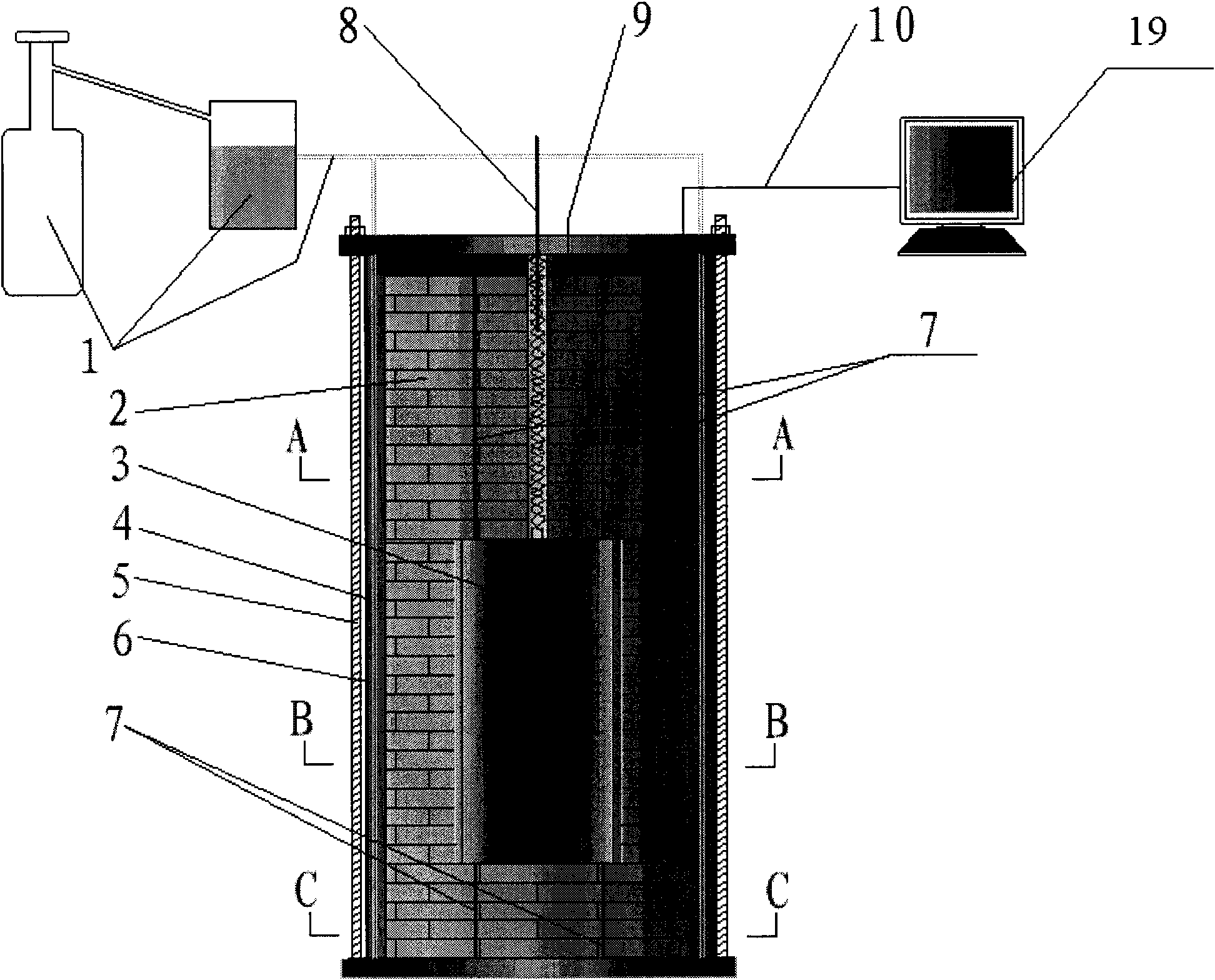

[0032] Such as Figure 1 to Figure 5 A system for simulating the characteristics of a high-level radioactive waste geological disposal room is shown, which can simulate the thermal-hydraulic-mechanical-chemical coupling characteristics of a high-level radioactive waste geological disposal room, including water supply and gas supply control device 1, temperature control device 8, multi-field Coupling experimental device, measurement system, data acquisition system 10 and data processing system 19;

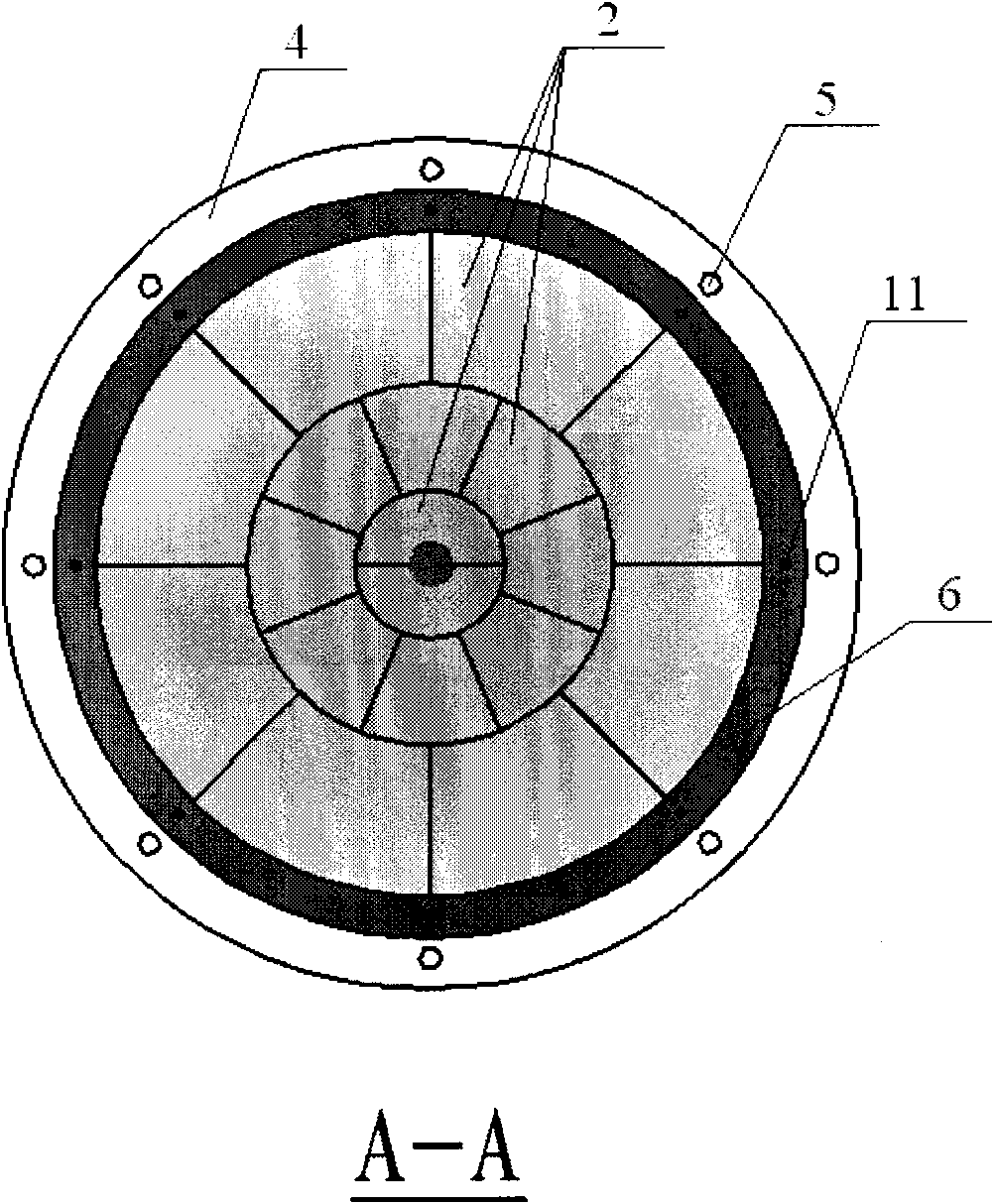

[0033] Among them, the system for simulating the characteristics of the geological disposal chamber of high-level radioactive waste takes the multi-field coupling experimental device as the core, and the multi-field coupling experimental device is a cylindrical multi-layer structure as a whole, and its outermost layer is a barrel-shaped stainless steel cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com