Storage battery glue-pouring machine

A technology of glue filling machine and battery, which is applied in the field of glue filling machine, can solve the problems that the glue filling process cannot be smooth and consistent, the pipeline is blocked, and it is easy to hang on the wall, so as to improve the quality of the colloidal electrolyte, ensure the consistency, and prevent the wall hanging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

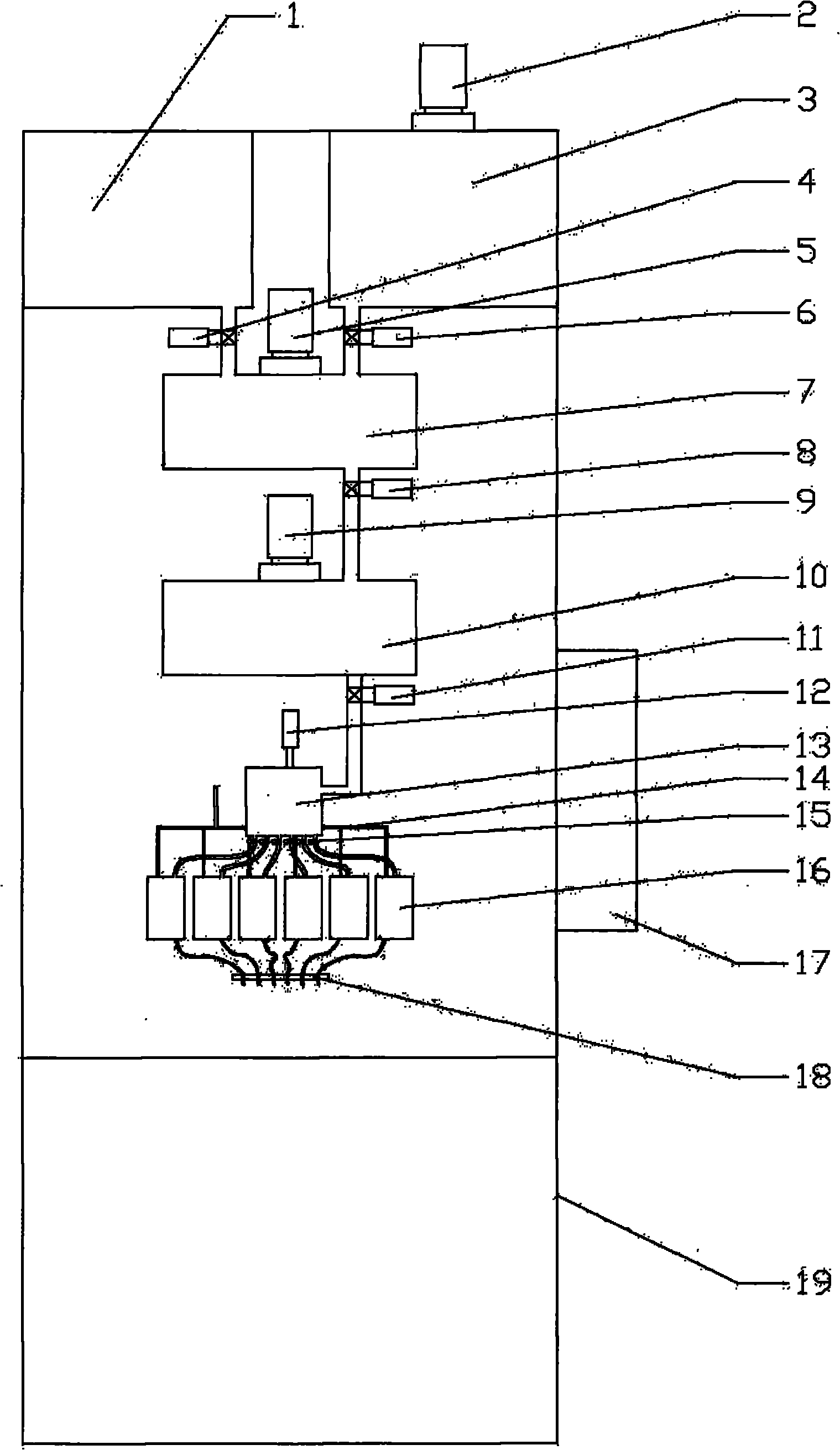

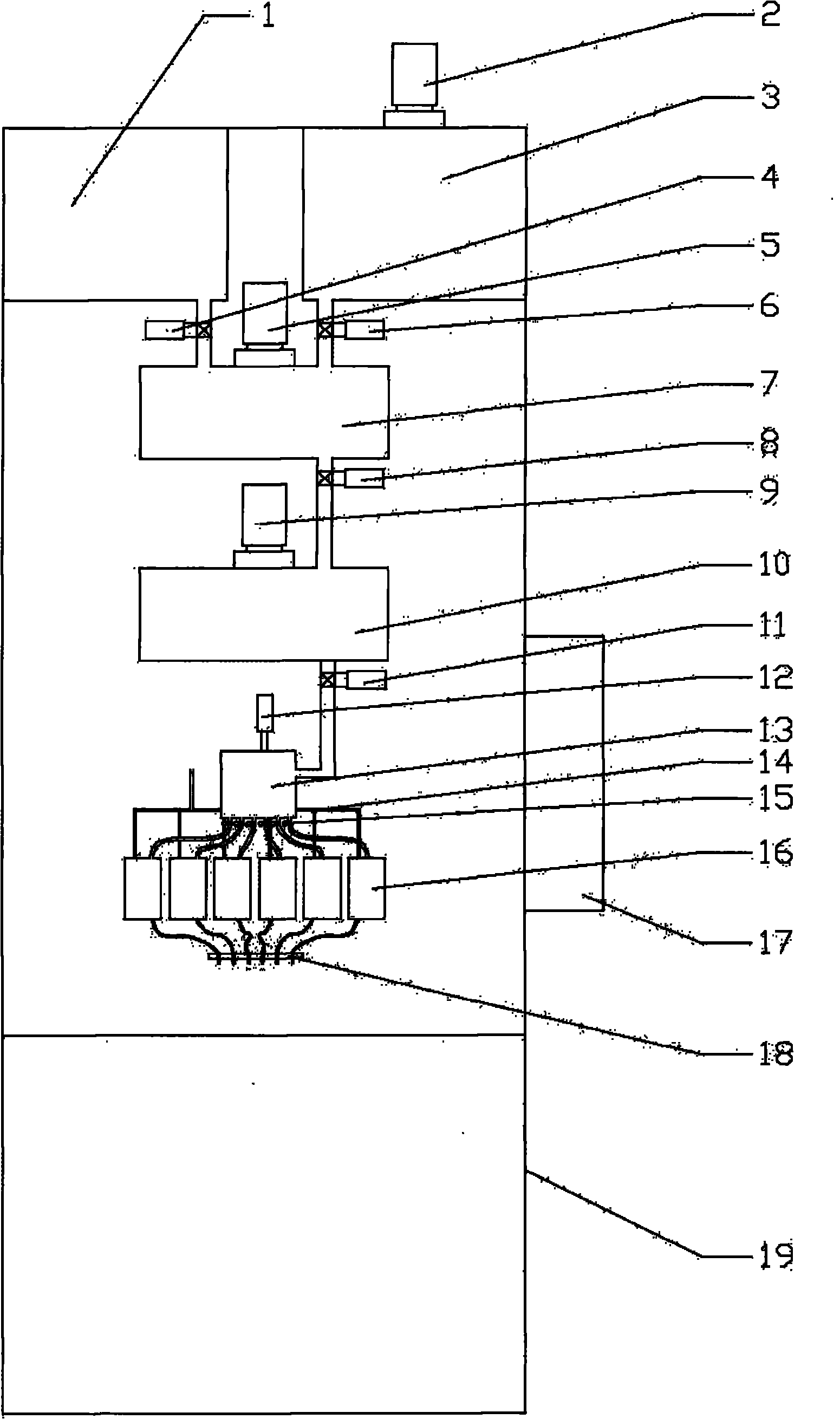

[0019] like figure 1 As shown, the battery glue filling machine includes a frame 19, and the frame 19 is provided with a glue dispensing system, a shearing system, a vacuum system and a controller system 17, and the glue dispensing system, the shearing system, and the vacuum The systems are all connected to the controller system 17, and the glue dispensing system, shearing system, and vacuum pumping system are connected in sequence. The glue distribution system includes acid storage tank 1, water glue shear machine 2, glue storage tank 3, sulfuric acid flow pump 4, glue distribution shear machine 5, water glue flow pump 6, glue distribution bucket 7, temperature control valve 8, storage Glue shearing machine 9 and glue storage bucket 10; Shearing system comprises liquid level valve 11, shearing machine 12 and shearing barrel 13, and vacuum system comprises the vacuum pumping pipe 14 that is connected to vacuum pumping machine, flow valve 15, buffer barrel 16 and glue filling ...

Embodiment 2

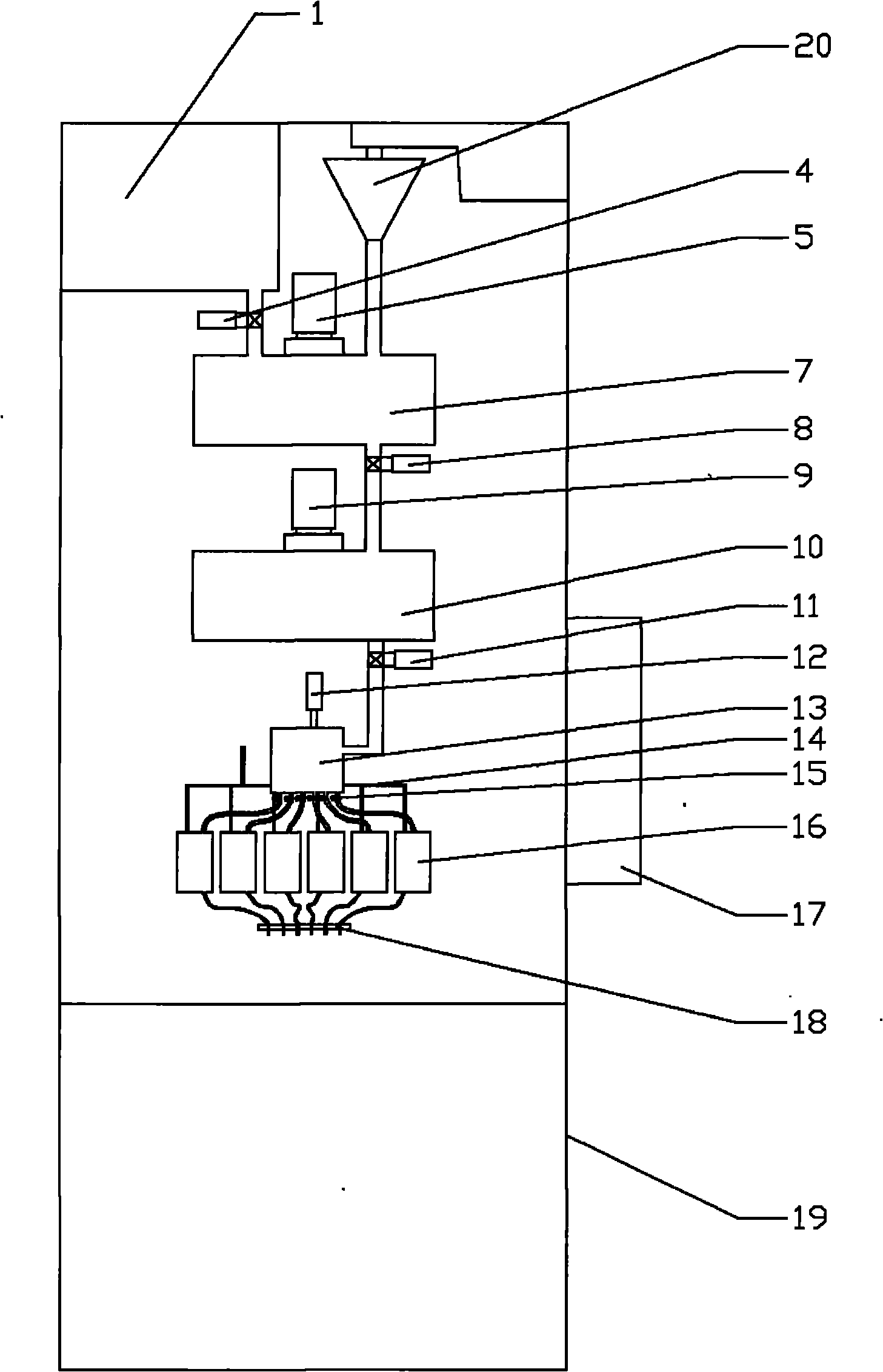

[0032] like figure 2 As shown, the structure of this embodiment is used to directly add silica powder to the glue mixing tank for glue compounding, use silica powder to directly prepare colloidal electrolyte, and replace the water gel scissors in Embodiment 1 by powder weighing machine 20 Cutting machine 2, glue storage tank 3 and water glue flow pump 6, other each parts are all unchanged, to realize same function.

[0033]In this way, in the setting of the controller system 17, the second part is changed to set the amount of sulfuric acid required for the colloidal electrolyte with the sulfuric acid flow pump 4 and the silicon dioxide amount required for the colloidal electrolyte with the powder meter 20 at one time, After the temperature of the acid in the acid storage tank 1 reaches the set process requirements, start the sulfuric acid flow pump 4 and the powder metering machine 20, start the glue dispensing shearer 5, prepare the concentration of each component of the col...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap