Drive axle for electric vehicle or hybrid electric vehicle

A technology for hybrid electric vehicles and electric vehicles, which is applied to the arrangement of multiple different prime movers of electric vehicles and general power units, electric power units, etc., can solve the problem of poor economic efficiency and competitiveness, poor vehicle endurance, and large space. and other problems, to achieve the effect of compact structure, improved general rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

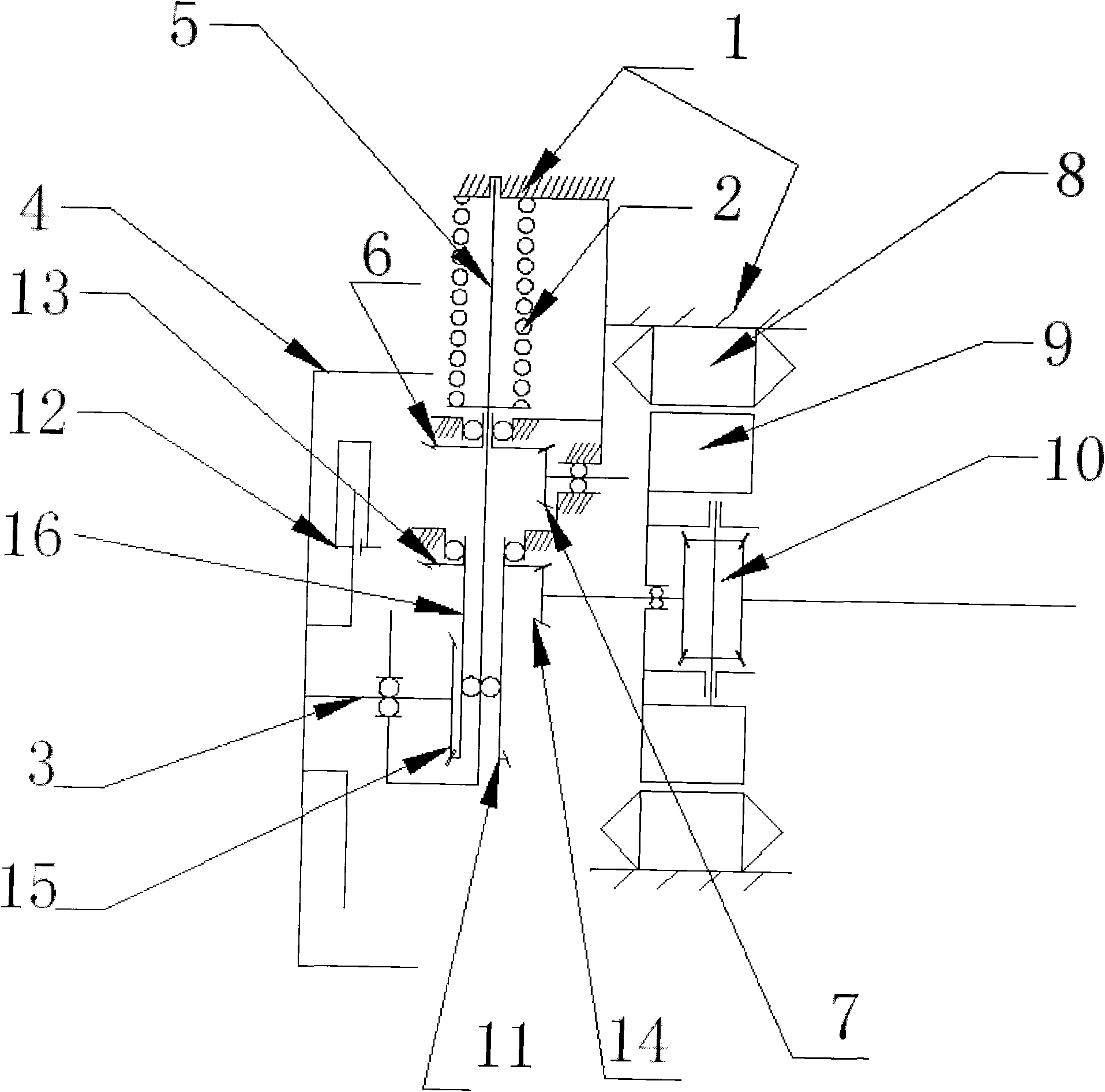

[0014] The present invention will be further described below in conjunction with the drawings.

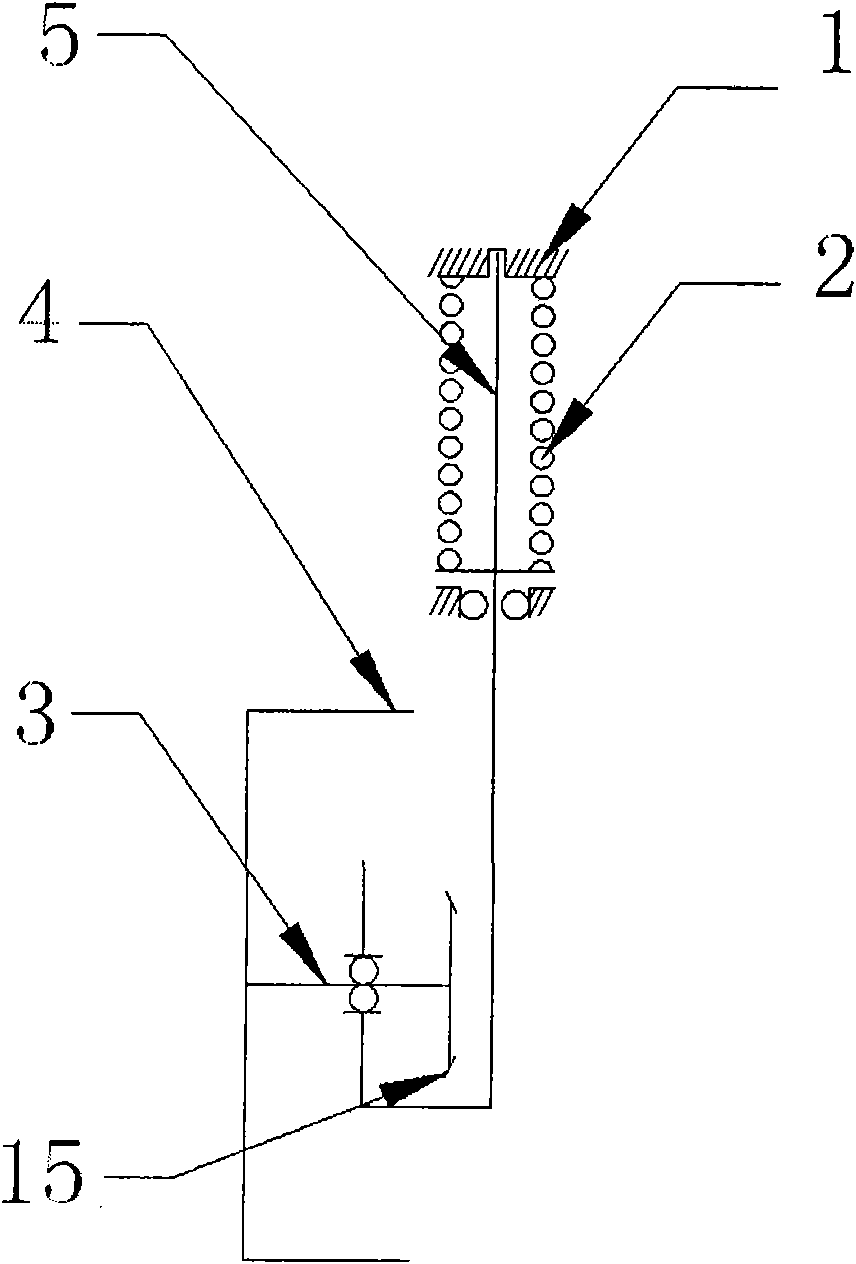

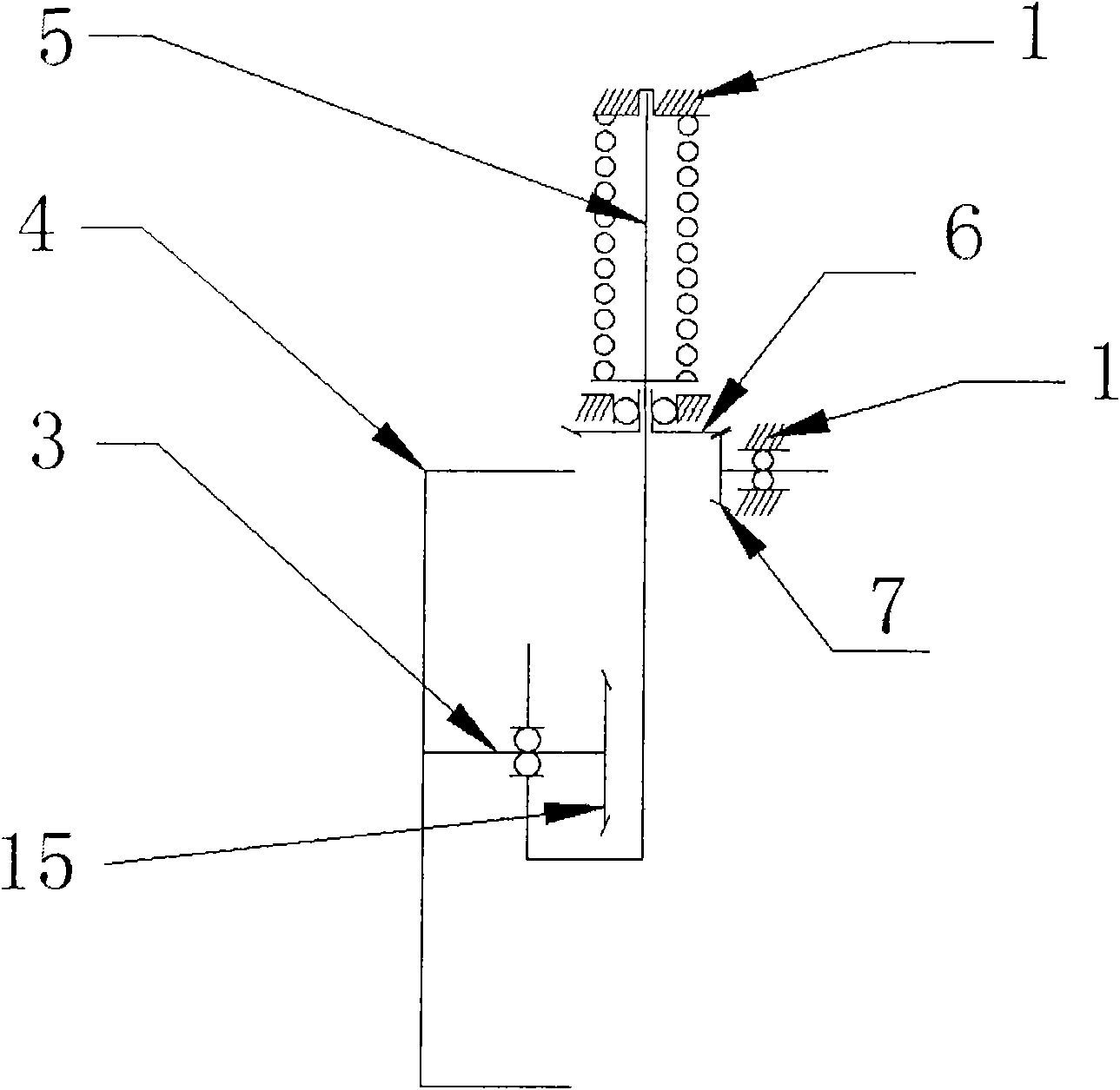

[0015] See figure 1 The drive axle shown for an electric vehicle or hybrid vehicle includes a motor stator 8 fixed on a vehicle body 1, a motor rotor 9 corresponding to the motor stator, and a differential 10 fixedly connected to the motor rotor. The drive bevel gear 14 is arranged on the output end of the half shaft that is matched with the differential, and the upper end is matched with the vehicle body 1 and the middle part is matched with the bearing provided on the vehicle body. The shock-absorbing steering shaft 5 is sleeved on the shock-absorbing steering shaft. One end of the upper part of the shaft is close to the car body 1 and the other end is a damping spring 2 which is close to the spring seat provided on the damping steering shaft. The steering input bevel gear 7 is matched and connected with the steering structure provided on the car body 1; The middle part of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com