Automatic acid storage battery supplementing liquid injecting machine of vehicle

An automatic liquid filling and replenishing technology, which is applied in vehicle maintenance, vehicle maintenance/repair, liquid distribution, transportation or transfer devices, etc., can solve the problems of difficulty in human observation, human damage, battery fluid waste, etc. Effects of waste and corrosion, ensuring personal safety and health, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

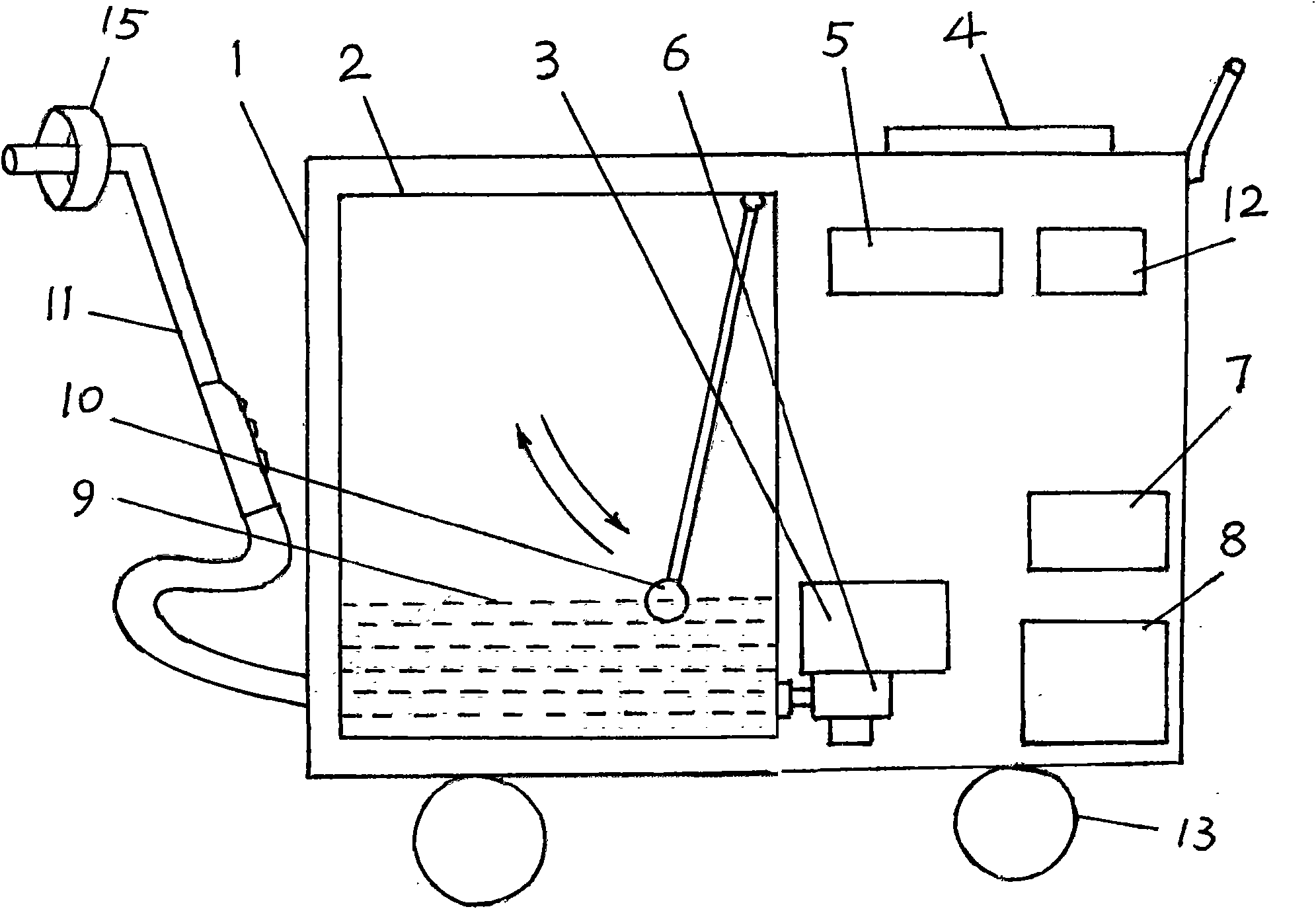

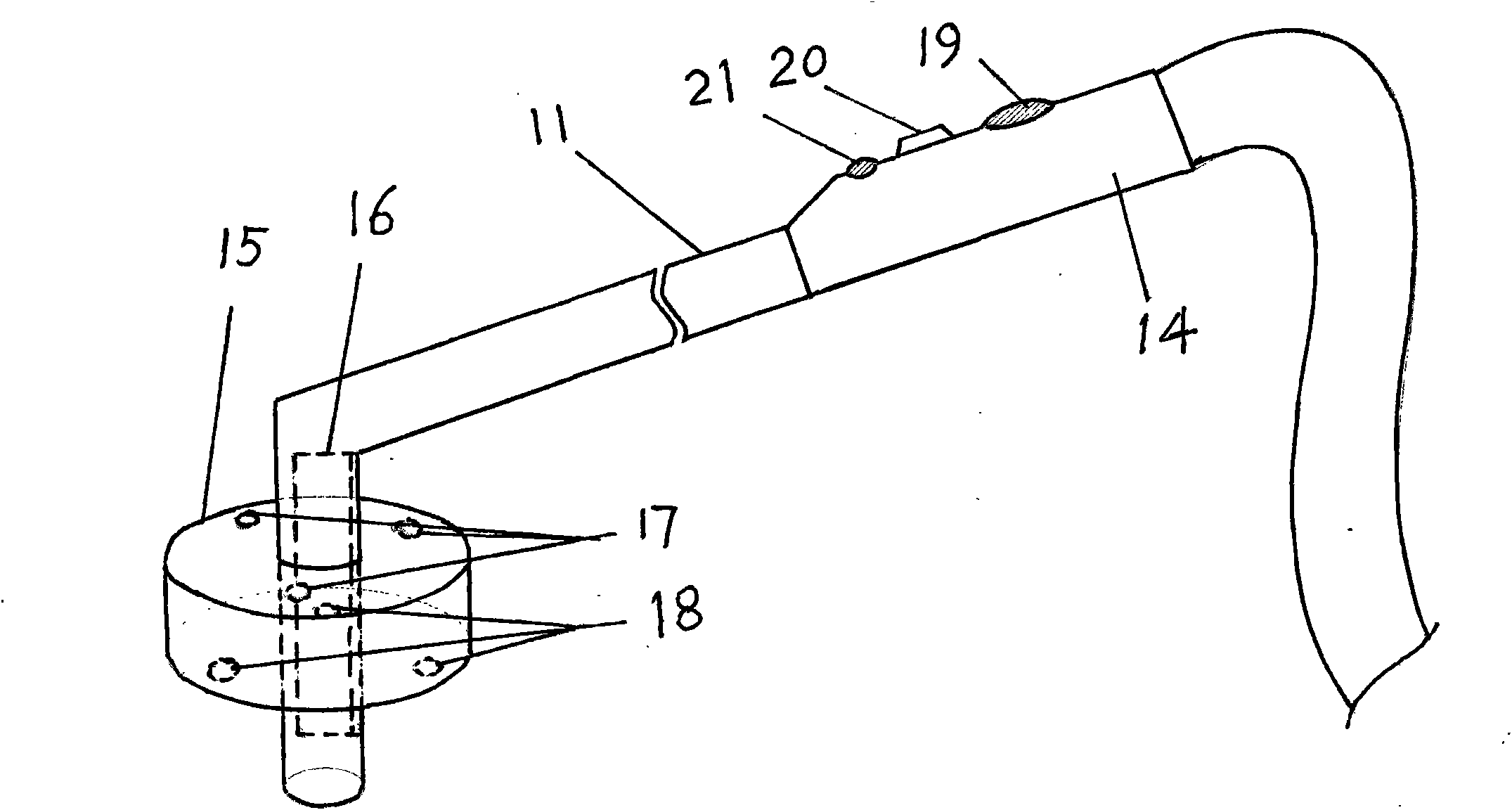

[0017] Refer to attached figure 1 , 2 As can be seen in the figure, the specific components of the present invention include: 1~casing, 2~inner tank (i.e. distilled water tank), 3~filling motor pump, 4~circuit control panel, 5~main control circuit with single-chip processor Module board, 6~Solenoid valve for filling, 7~Charger, 8~Battery (operating power supply), 9~Inner tank distilled water, 10~Inner tank water level detection ball valve, 11~Filling gun, 12~Power supply module board , 13~ small roller, 14~ filling gun grip handle, 15~ gun head cover, 16~ gun head infrared detection line group (including infrared emitting diode, infrared receiving diode and positioning float), 17~ automatic contact switch group SW2, 18~light group LED1, 19~light switch SW4, 20~standby switch SW3, 21~working indicator LED2;

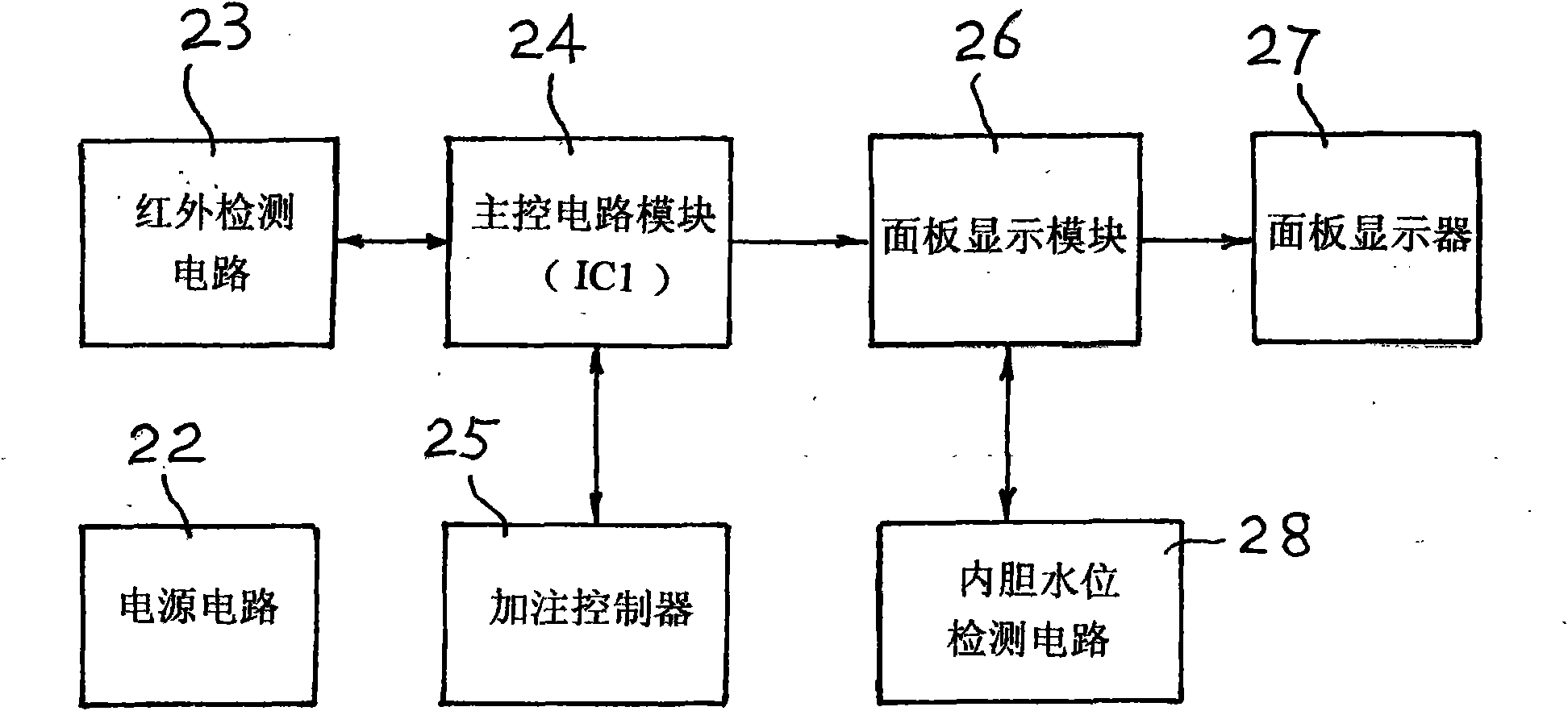

[0018] in the attached image 3 , 4 Middle: 22~power supply circuit (module), 23~(at the gun head) infrared detection circuit (module), 24~main control circuit module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com